Device and method for online measuring polymer melt rheological parameter

A melt rheology and polymer technology, applied in the direction of DC flow characteristics measurement, etc., to reduce the impact and reduce the effect of test error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

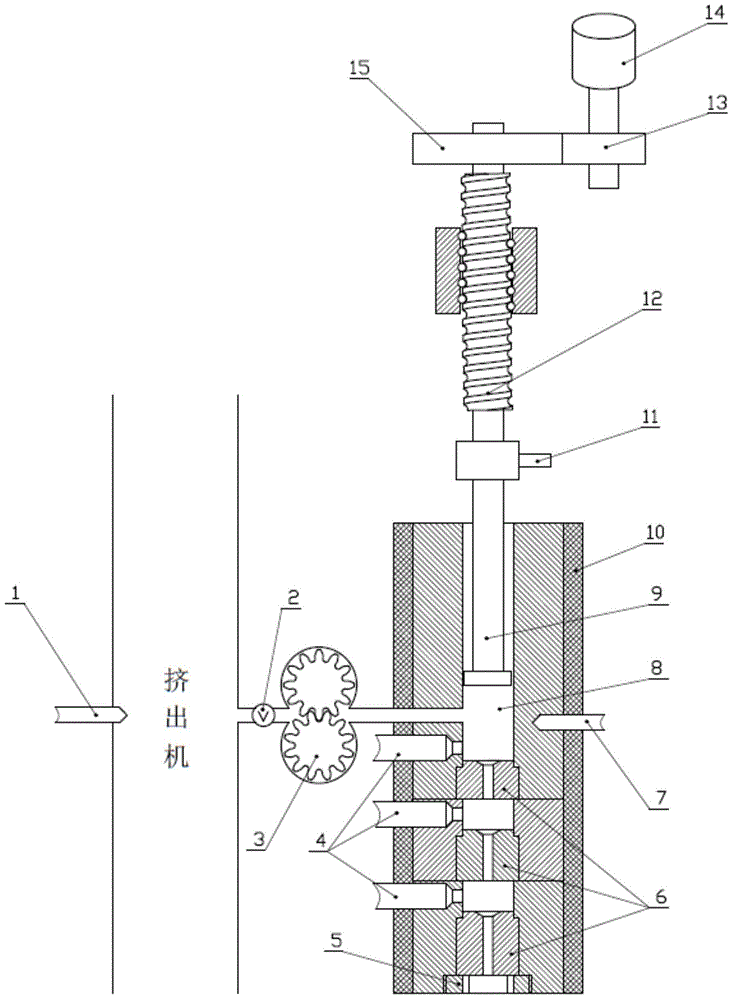

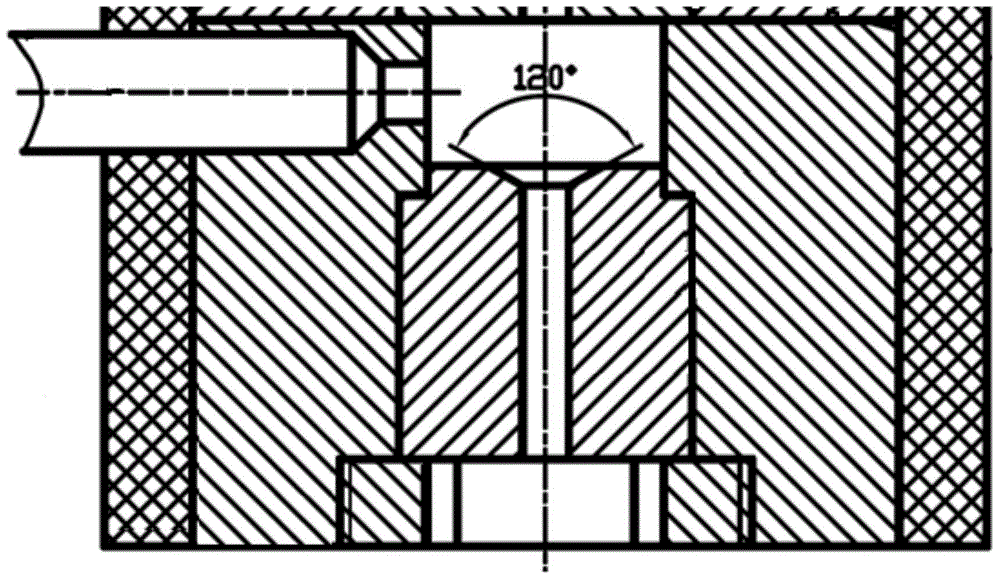

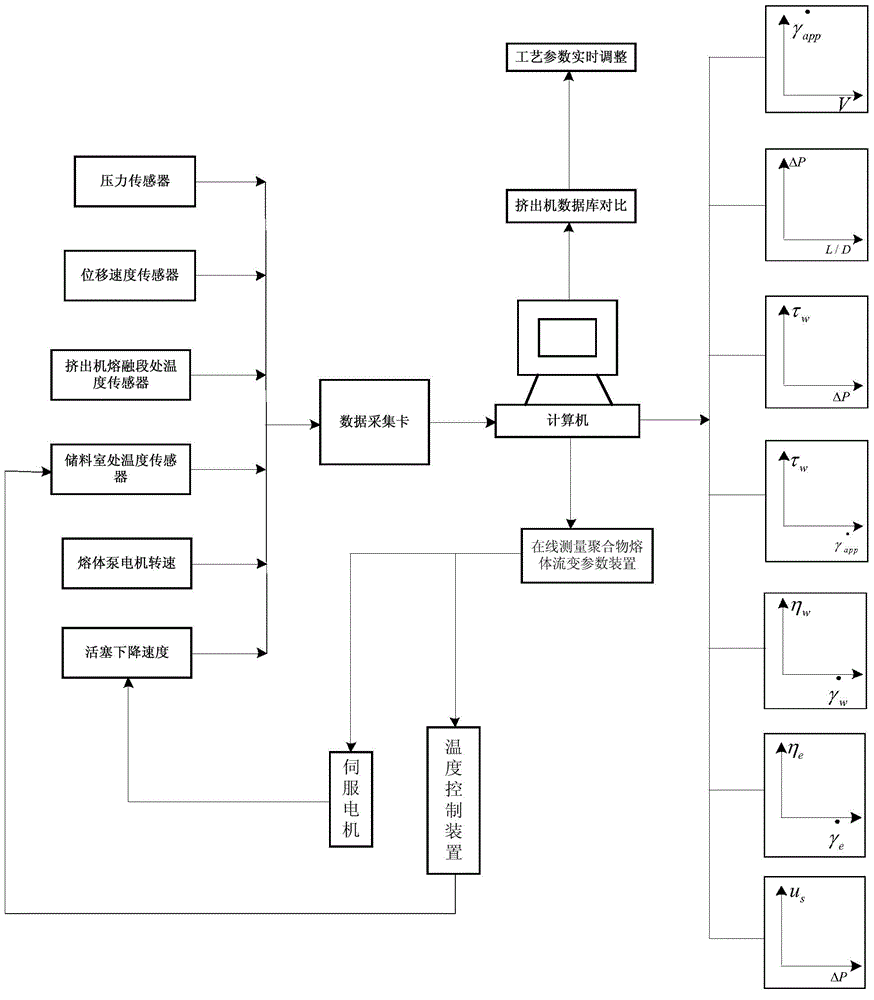

[0030] Such as Figures 1 to 3 shown. The device for measuring the rheological parameters of polymer melt on-line according to the present invention comprises a temperature control device 10, a housing of the temperature control device 10 has a storage chamber 8; the top of the storage chamber 8 is a piston with a piston 9 section, the bottom of the storage chamber 8 is the polymer melt extrusion section, in which a plurality of capillary dies spaced apart from each other are arranged sequentially from top to bottom; at the entrance of each capillary die 6, a pressure sensor 4;

[0031] The storage chamber 8 is connected to the melting and plasticizing section of the extruder through the melt pump 3, and the melt pump 3 introduces the polymer melt into the storage chamber 8 from the melting and plasticizing section of the extruder, and the extrusion of the piston 9 pressure, so that the polymer melt in the storage chamber 8 is extruded from a plurality of capillary dies 6 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com