Optical excitation and ultrasonic excitation combined infrared nondestructive testing device

A technology of infrared non-destructive testing and composite excitation, which is applied in the direction of optical testing for flaws/defects, etc. It can solve problems such as short excitation energy and excitation time, failure to detect internal damage, and limited detectable depth, so as to improve detection accuracy and sensitivity. , Make up for the lack of detection ability, reduce the effect of false detection and missed detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments are described in detail below in conjunction with the drawings. It should be emphasized that the following description is only exemplary, and is not intended to limit the scope and application of the present invention.

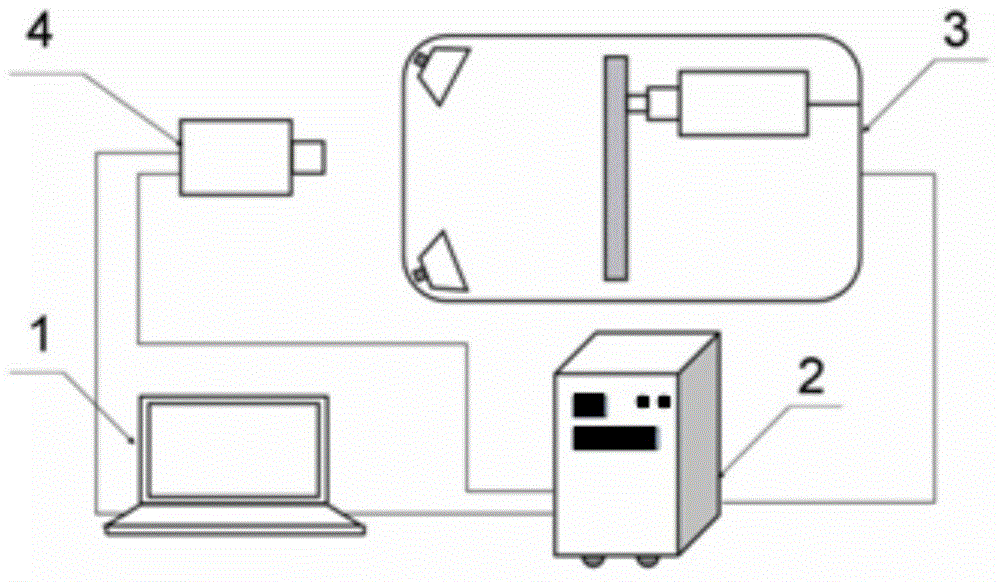

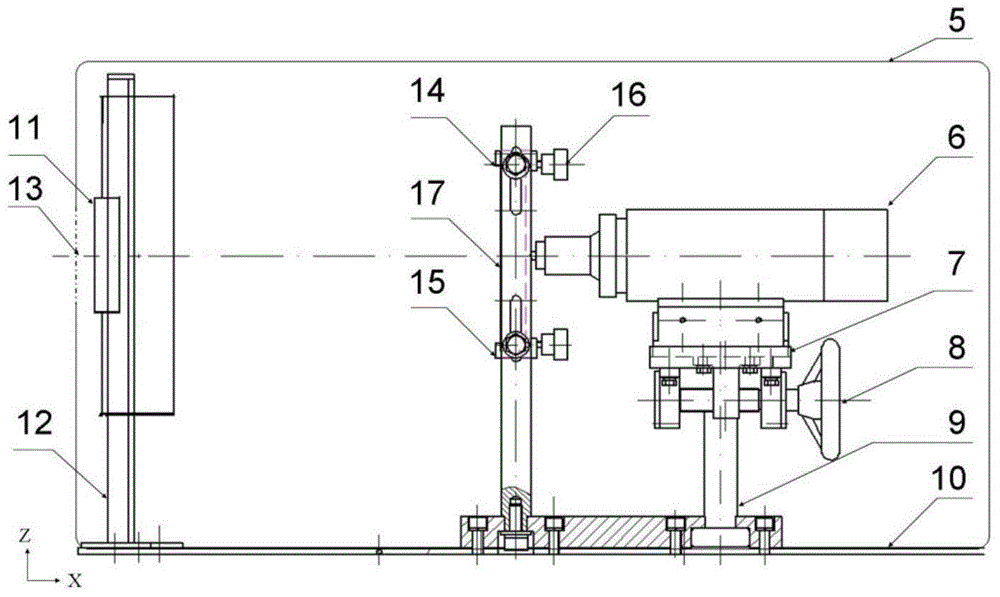

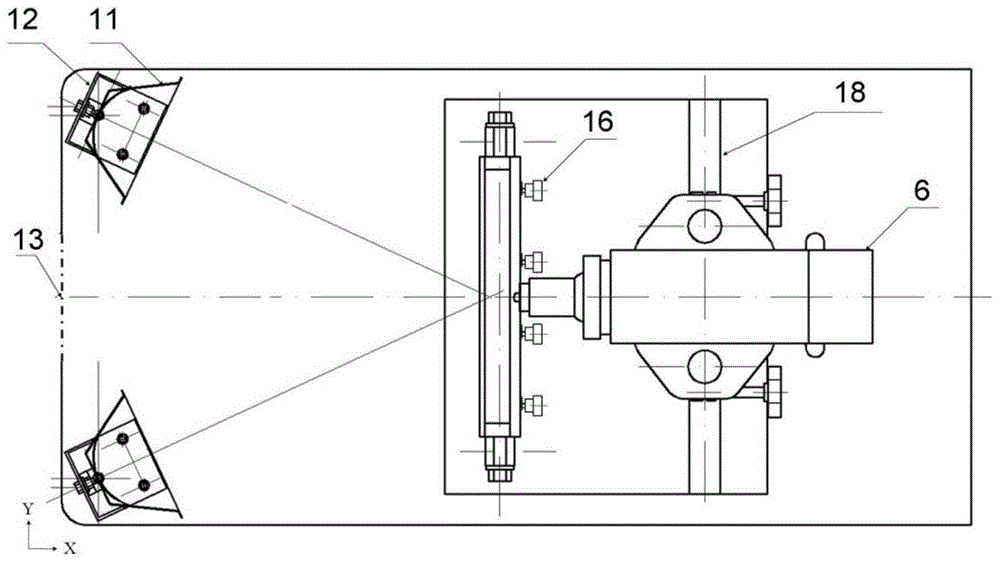

[0027] figure 1 It is a schematic diagram of the structure of the infrared thermal wave nondestructive testing system provided by the present invention. figure 1 Among them, the infrared non-destructive testing device provided by the present invention is composed of a computer 1, a control cabinet 2, an excitation system 3 and an infrared thermal imager 4. The computer 1 is connected to the infrared thermal imager 4 through the IEEE1394 interface to collect and process infrared thermal images; it is connected to the control cabinet 2 through the RS232 communication line to control the test process. The control cabinet 2 is connected to the infrared thermal imager 4 through a trigger circuit to perform a synchronous external trigge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com