Fly-eye lenses and optical systems comprising same

A fly-eye lens and optical system technology, applied in the field of illumination devices, can solve the problems of high cost, unsatisfactory uniformity, different illumination intensity, etc., and achieve the effect of improving uniformity and intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

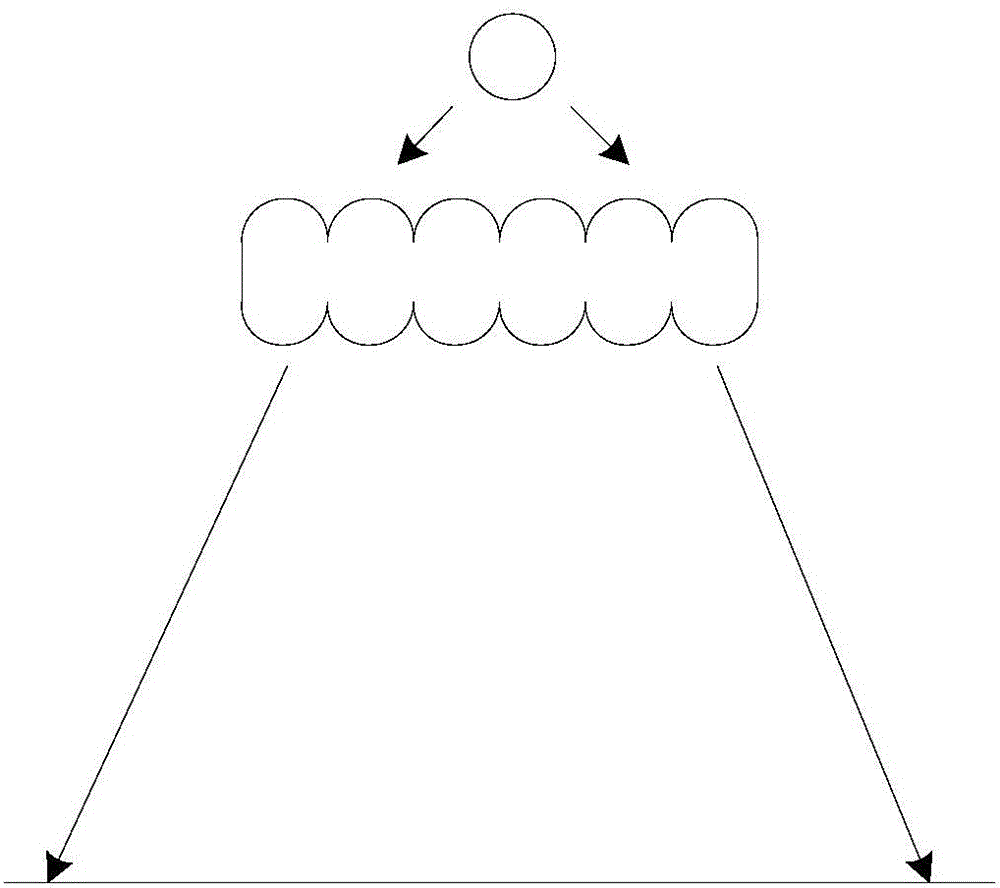

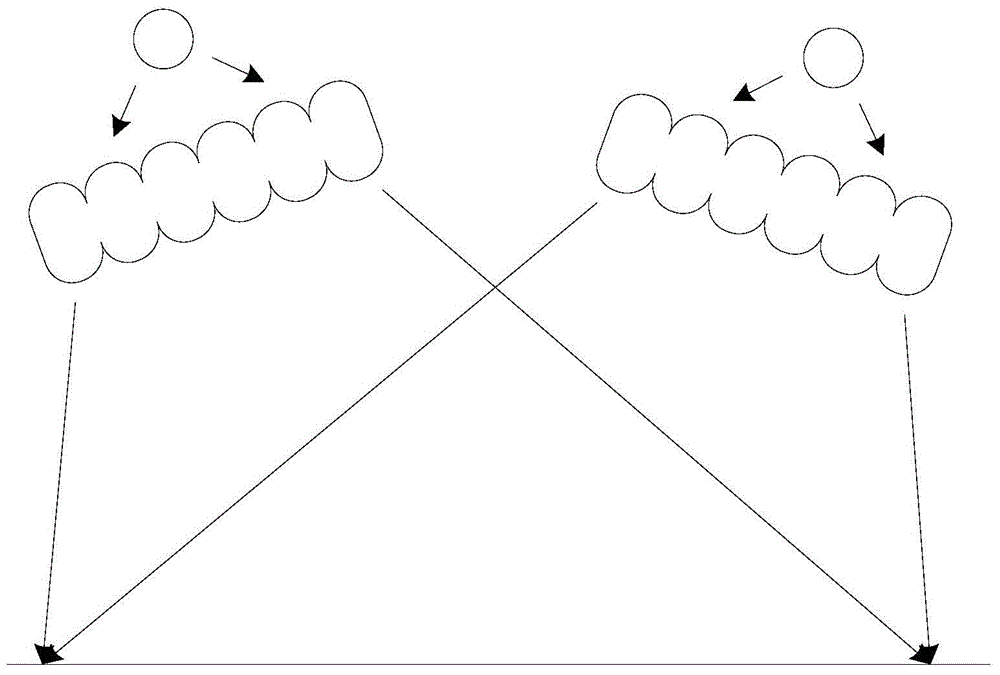

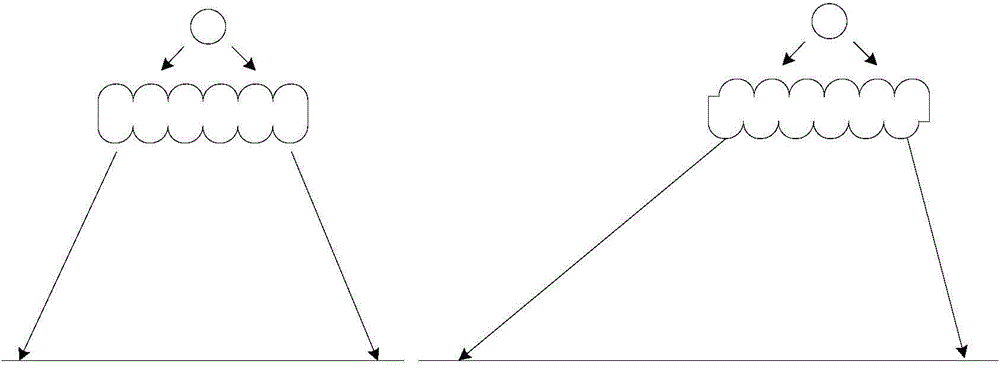

[0044] In order to achieve the purpose of the present invention, as image 3 , 4 As shown in and 6, in some embodiments of the fly-eye lens of the present invention, it includes a base 1 and a plurality of lens units 2 arranged on opposite sides of the base 1, and the lens units 2 are arranged obliquely relative to the base. Among them, the manufacturing materials and process of the fly-eye lens are no different from the prior art. The present invention is only a structural change, and the manufacturing materials and processes do not belong to the improvement of the present invention. Therefore, the specific manufacturing materials and processes used Processes and the like can be based on prior art, and will not be listed in detail here.

[0045] combine image 3 , 4As shown in and 6, the fly-eye lens is a double-sided fly-eye lens, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com