AGV (automated guided vehicle) intelligent material distribution vehicle

A cloth vehicle, intelligent technology, applied in the direction of two-dimensional position/channel control, etc., can solve the problems of inconvenient disassembly of the power mechanism, no automatic cloth, and insufficient flexibility in steering, so as to improve work safety and stability, and facilitate maintenance. The effect of improving work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

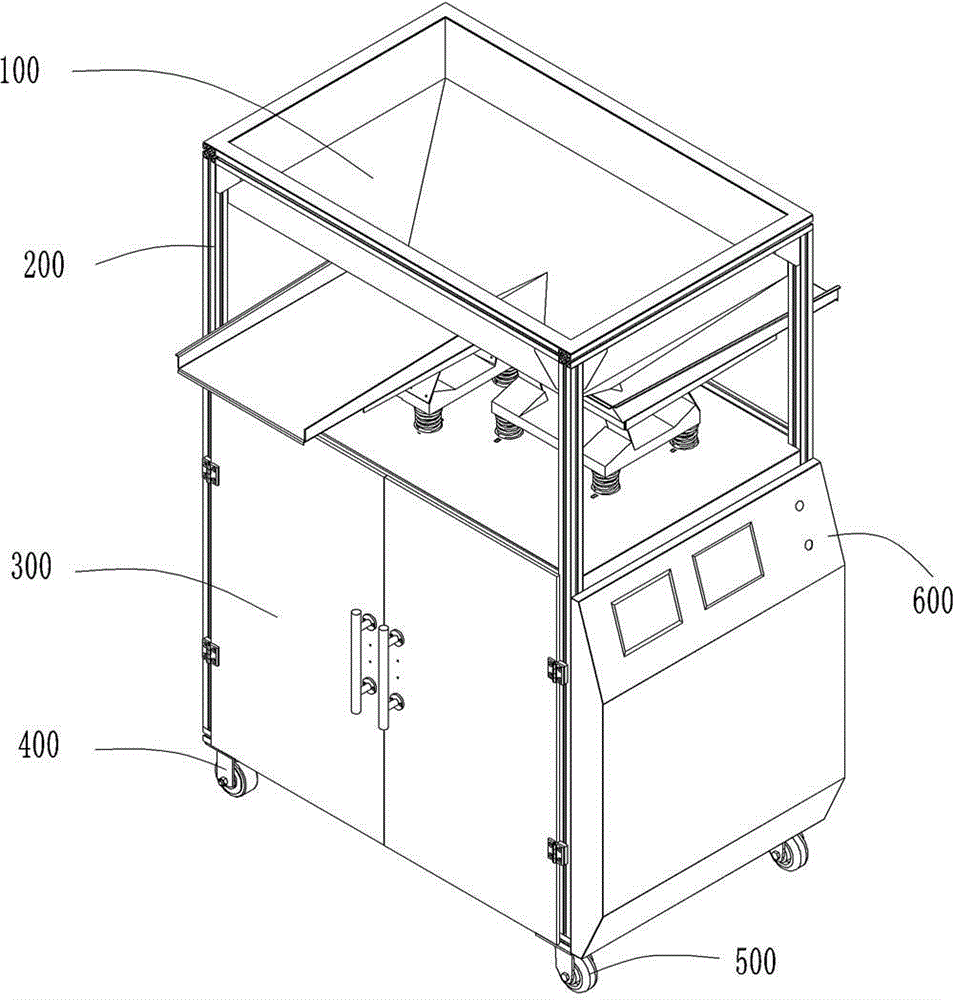

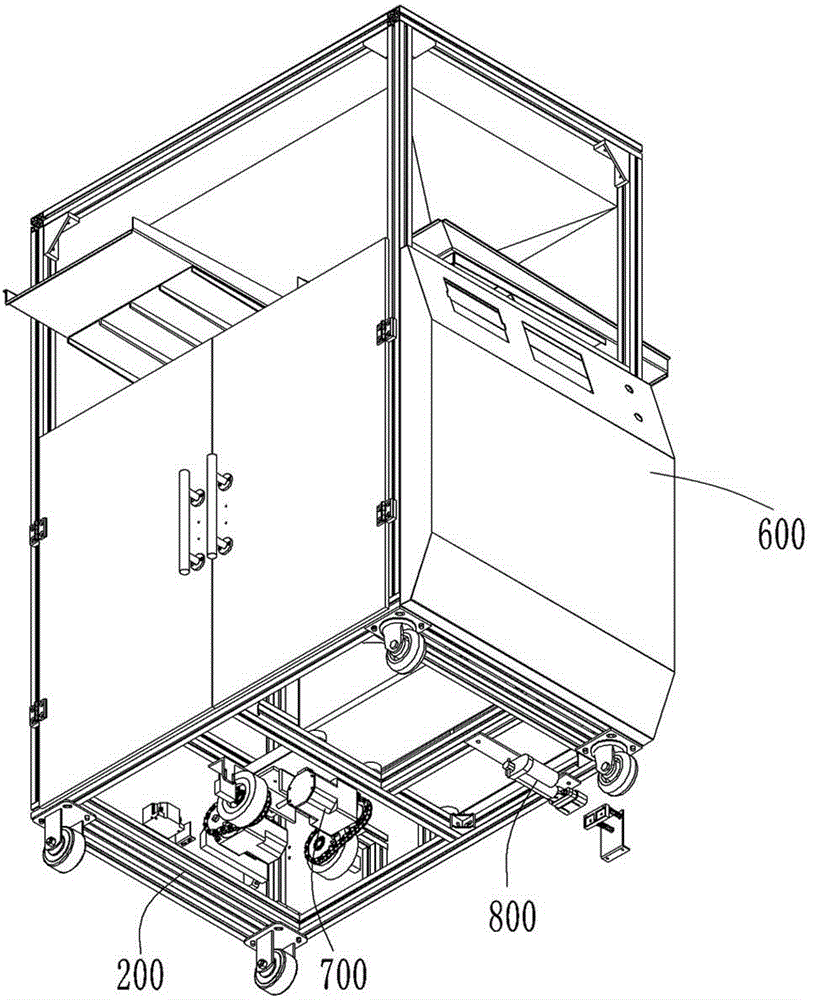

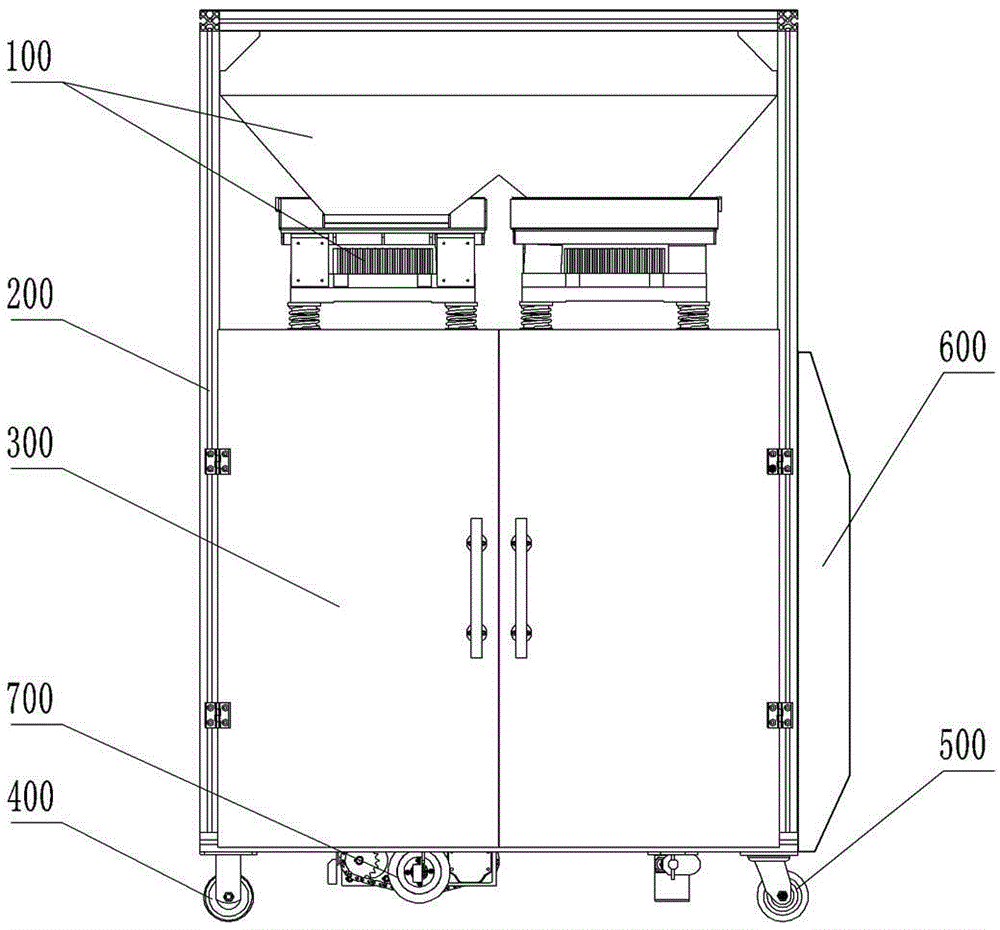

[0037] Embodiment 1: see Figure 1 to Figure 11 , an AGV intelligent cloth vehicle, including a car body, a driving part, a walking part, and a battery installed on the car body frame, a cloth part, an operation panel, and an automatic charging part, and the lower part of the car body frame is fixed on the car body frame The baffle plate forms a control room, and the control room is provided with a controller part and a guide part; the walking part is arranged on the bottom surface of the car body frame, and the driving part is arranged under the car body and is connected to the car body through a shock-absorbing connection device. The lower part of the car body frame is connected in the middle.

[0038] In the above structure, the shock-absorbing connection device includes a bracket, an adapter frame, a drive frame and a shock-absorbing mechanism, the bracket is connected to the lower part of the vehicle body frame, and the drive frame is connected to the bracket through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com