Pre-spinning-colored fiber color testing and matching method

A pre-spinning coloring and fiber technology, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

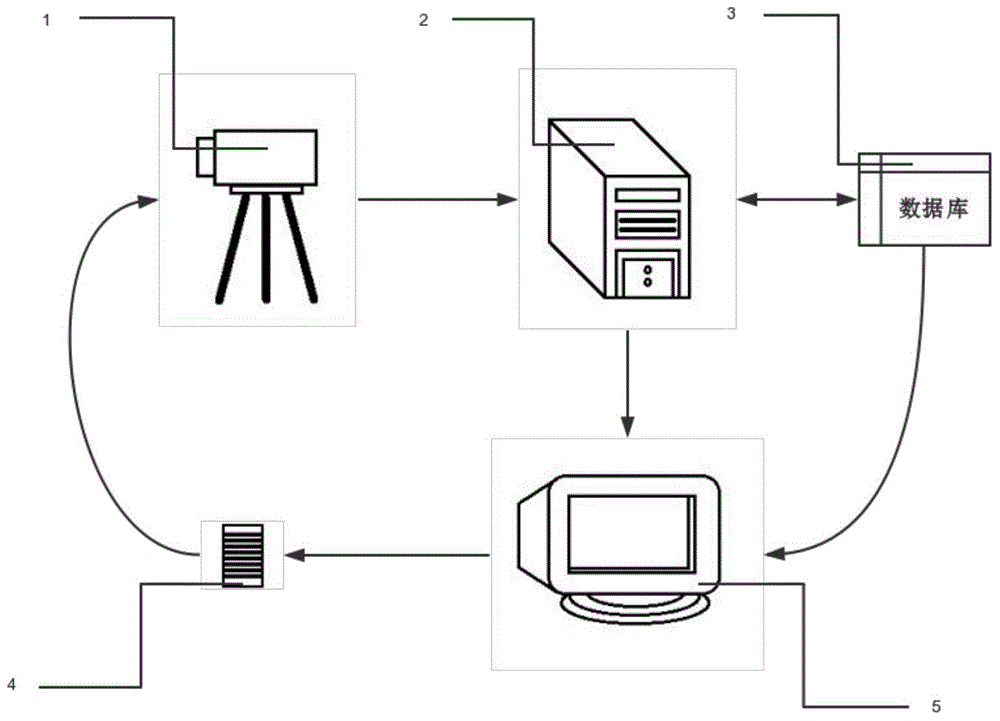

[0034] Such as figure 2 As shown, it is a schematic diagram of the composition and structure of the system used in the method for measuring and matching color of pre-spinning colored fibers in this embodiment: 1 is the DigiEye color measuring system; 2 is a computer host with computing power; 5 is a display connected to the host computer for displaying formula information and object images in the database; 4 is the actual coloring fiber sample produced before spinning according to the optimized formula of the method for measuring color matching of the present invention.

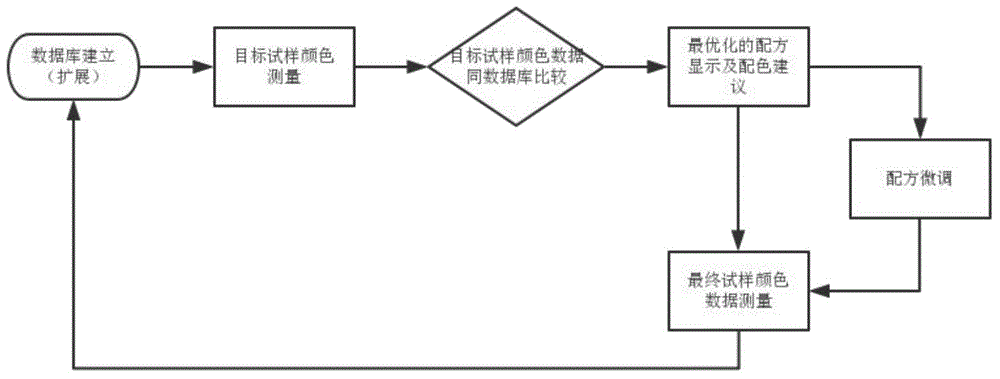

[0035] Such as figure 1 As shown, a kind of pre-spinning colored fiber measuring and matching method of the present embodiment comprises the following steps:

[0036] (1) Establish a database for the relevant data of the existing pre-spinning colored fiber samples.

[0037]The produced pre-spun colored fiber is evenly wound on the glass slide. During the winding process, the surface of the filament needs t...

Embodiment 2

[0048] (1) Establish a database for the relevant data of the existing pre-spinning colored fiber samples.

[0049] The produced pre-spun colored fiber is evenly wound on the glass slide. During the winding process, the surface of the filament needs to be kept flat to ensure the accuracy of the color measurement data. The glass slide wound with the pre-spun colored fiber is passed through the The DigiEye color measurement system of British Verivide company obtains the color data and sample image of the pre-spun dyed fiber sample, and builds a database for the color data (Lab value and RGB value) and image of the sample. The establishment and management of the database can be done through Microsoft Office Access 2007 database software. At the same time, the formula information (selection and proportion of raw material masterbatch) of the above samples is also imported into the established database, and the sample number is used as the only mapping method between the two.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com