Drilling rig part internet-of-things integration system based on bar code identification

A technology for rig parts and barcode identification, applied in logistics, instruments, data processing applications, etc., can solve the problems of many users complaining, slow response, simple organization, etc., to improve work efficiency, reduce workload, and facilitate operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

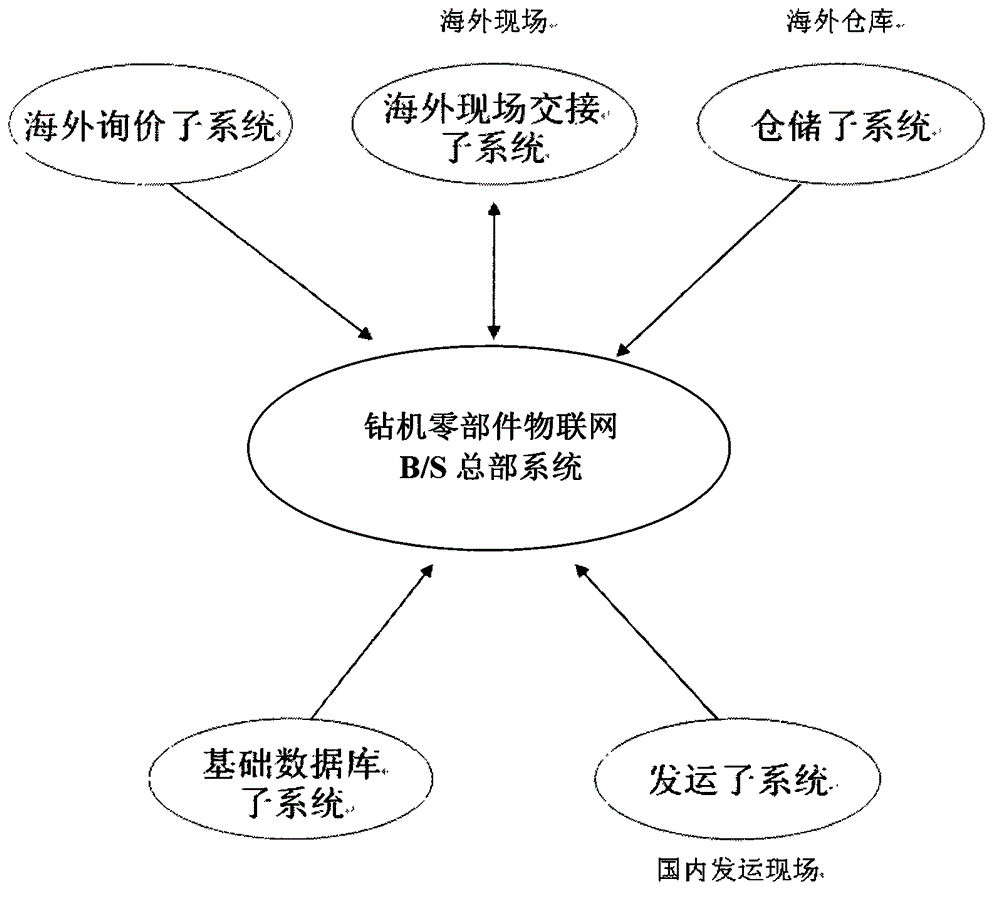

[0141] An integrated system of the Internet of Things for drilling rig parts based on barcode identification. The integrated system for the Internet of Things of drilling rig parts includes: basic database subsystem, overseas inquiry subsystem, shipping subsystem, overseas site handover subsystem, and storage subsystem. A C / S subsystem and a B / S headquarters system of the Internet of Things for drilling rig parts. in:

[0142] The basic database subsystem is the data source of the whole set of drilling rig components IoT integration system. The basic database subsystem helps the operators to import the original complicated basic data such as various drilling rig parts catalogs, drilling rig information, and shipping information into the system for standardized management, and can release the sorted data to other various departments. system as a data source.

[0143] The basic database subsystem includes: basic data import unit, basic data maintenance unit, basic data release...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com