Stator winder

A stator winding and stator technology, applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of inability to save metal consumables, low efficiency of manual winding, unstable precision, etc., to improve synchronous production efficiency , save labor costs and material costs, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in further detail by the following examples.

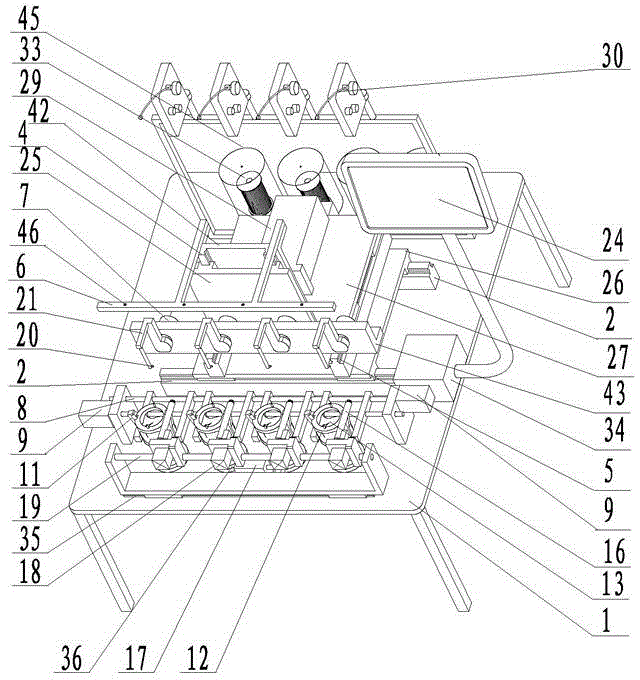

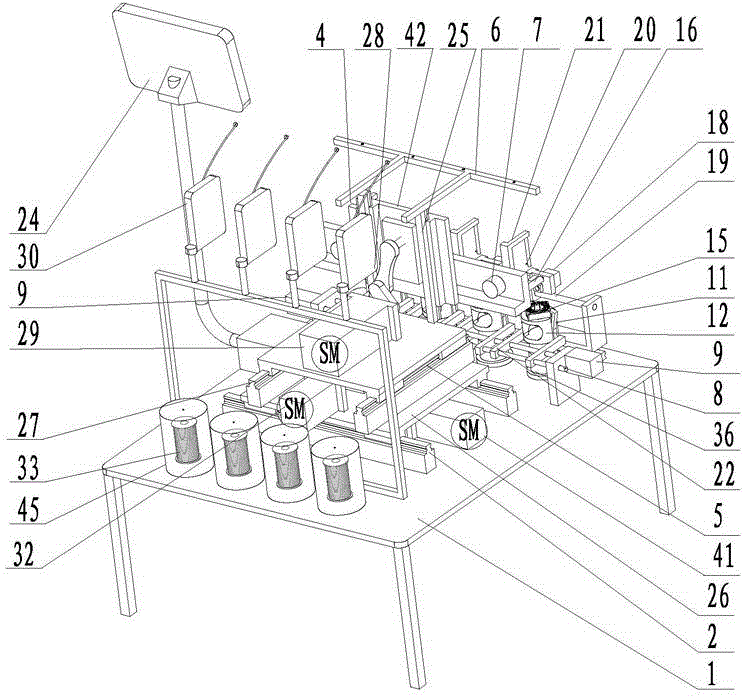

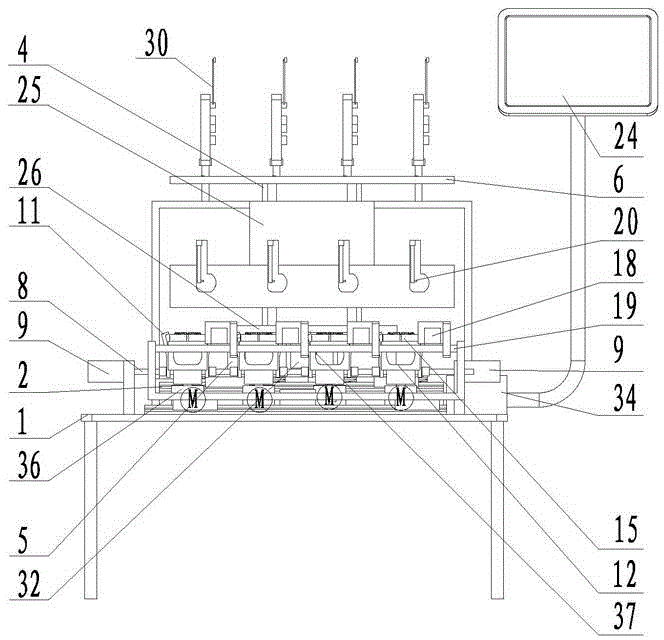

[0034] see Figure 1 to Figure 7 As shown, a stator winding machine is provided with a frame 1, a fixture table, a workbench and a console.

[0035]The fixture table is provided with a stator fixture seat 12, the stator fixture seat 12 is hollow and has a stator insertion groove 13, the stator body 15 is placed in the stator insertion groove 13, and the stator fixture seat 12 side is provided with a stator fixing device to clamp the stator body 15 , the stator clamp seat 12 is provided with a wire clamping / breaking device, and the lower part of the stator clamp seat 12 is provided with a stator clamp seat drive motor 36 to drive the stator clamp seat 12 to rotate and reciprocate; the stator fixing device includes a clamping claw 11, a connecting rod 8 1. Clamping claw cylinder 9, clamping claw 11 is installed on the side of the stator clamp seat 12, the shape of the upper part of the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com