Circuit arrangement for inductively heating at least one fuel injector, fuel injector arrangement comprising the circuit arrangement, and method for operating the circuit arrangement and the fuel injector arrangement

A circuit device, fuel injection technology, applied in the direction of fuel injection device, valve heating/cooling device, fuel injection control, etc., to achieve the effect of saving lines, reducing costs, and avoiding sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

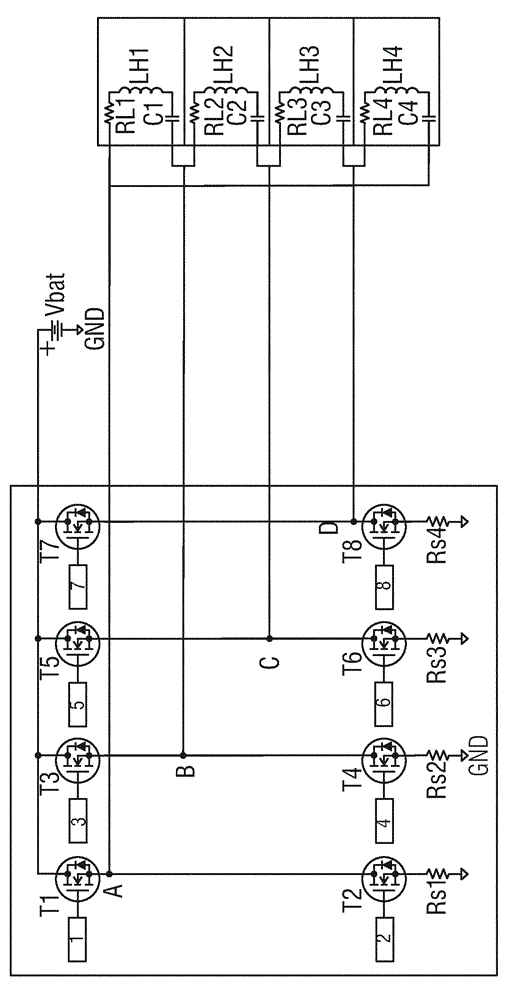

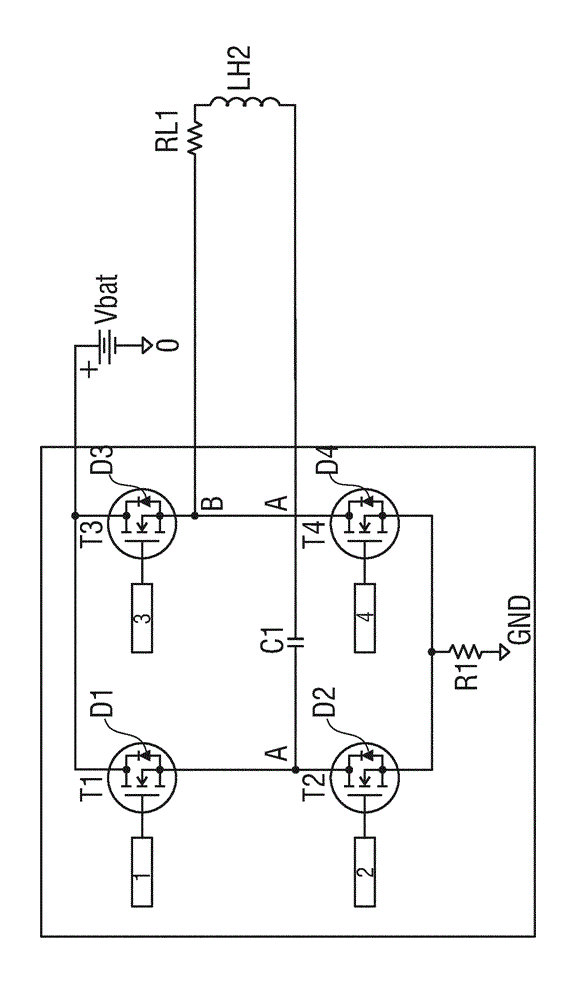

[0037] in accordance with figure 1 In the circuit arrangement of , a first series circuit is electrically connected between the positive pole Vbat and the negative pole GND of the voltage supply device, the first series circuit consisting of a first controllable switching element configured as a field effect transistor with a substrate diode D1 T1 is formed with a second controllable switching element T2, which is likewise designed as a field-effect transistor with a substrate diode D2. The connection point of the two switching elements T1 , T2 forms a first connection node A.

[0038] In the same way, between the positive pole Vbat and the negative pole GND of the voltage supply means is electrically connected a second series circuit consisting of a third controllable switching element T3 constructed as a field effect transistor with a substrate diode D3 and a fourth controllable switching element T4 configured as a field effect transistor with a substrate diode D4. The con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com