Fully automatic CNC dehydration treatment system

A processing system and fully automatic technology, applied in food processing, seed preservation through drying, climate change adaptation, etc., can solve the problems of low energy utilization rate, many auxiliary components, complex structure, etc., to avoid heat loss and operation The effect of convenience and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

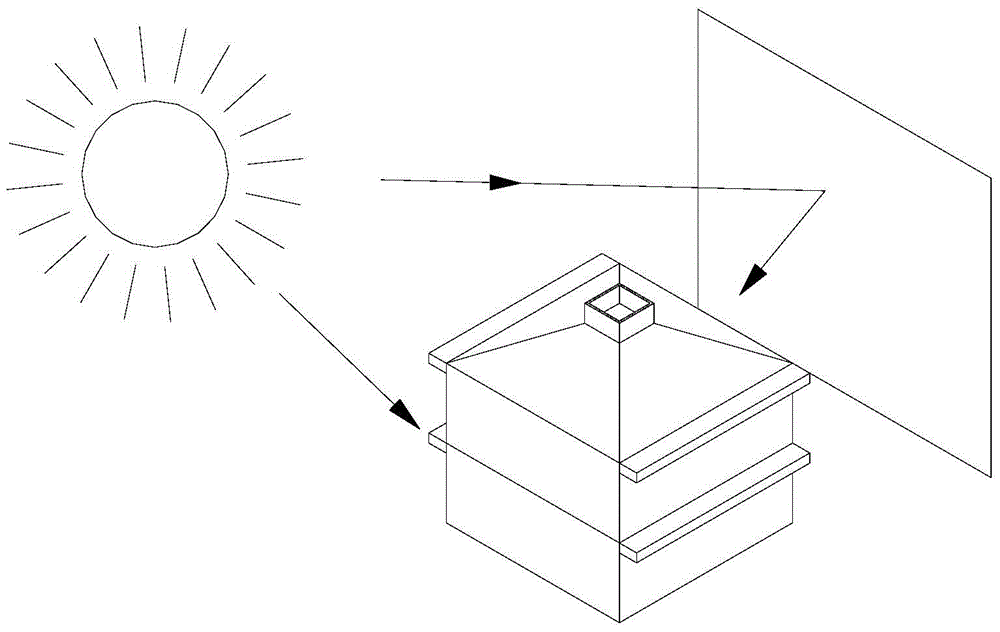

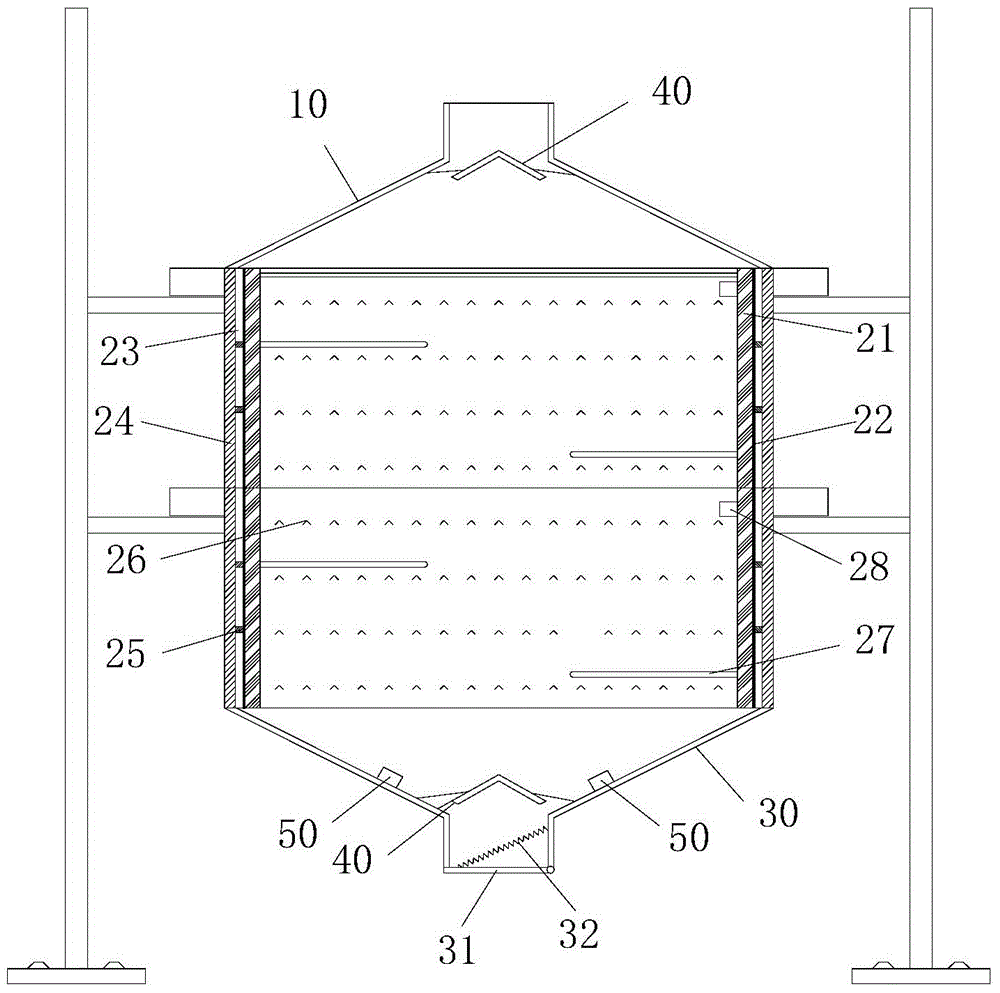

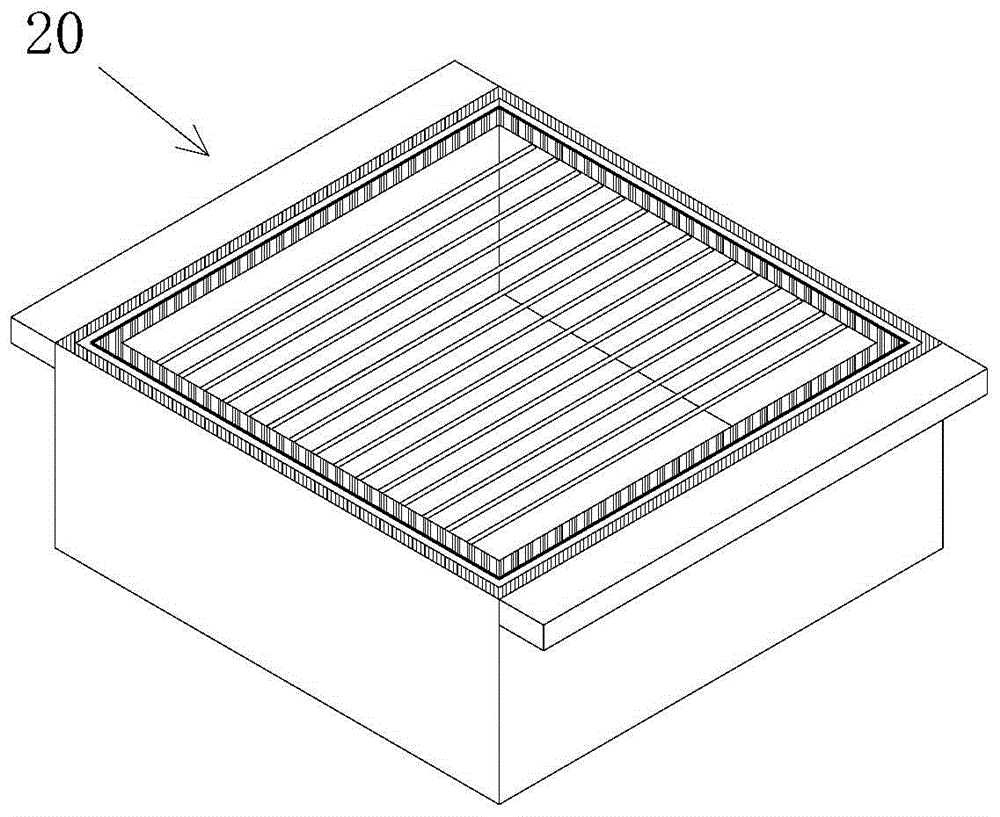

[0025] combined with Figure 1~3 The present invention is further described:

[0026] A fully automatic numerical control dehydration treatment system, comprising two solar ovens 20 connected in series, an upper cover 10 provided with an inlet and a lower cover 30 provided with an outlet, the upper cover 10 being arranged on the upper end of the solar oven 20 At the opening, the lower cover 30 is arranged at the opening of the lower end of the solar oven 20; the solar oven 20 includes a hollow shell 21, and the hollow shell 21 is square, or oval, fan-shaped, round Shape and other shapes, the outer wall of the hollow shell 21 is provided with a heat absorbing film 22, a vacuum heat insulation layer 23, and a tempered glass cover 24 in sequence from the inside to the outside, and the tempered glass cover 24 is fixed on the hollow shell by a compression screw. Outside the outer wall of the body 21, the hollow casing 20 is provided with longitudinal heat dissipation connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com