All-leather shoes for wearing indoors and manufacturing method of all-leather shoes

A production method and technology of leather shoes, applied in the field of shoes, can solve the problems of incomplete drying and disinfection, uneconomical, difficult to remove peculiar smell, etc., and achieve the effects of not being prone to foot diseases, simple and strong structure, and high heat preservation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

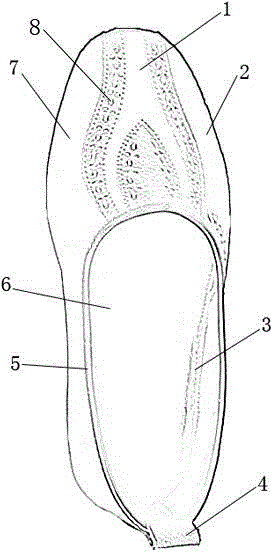

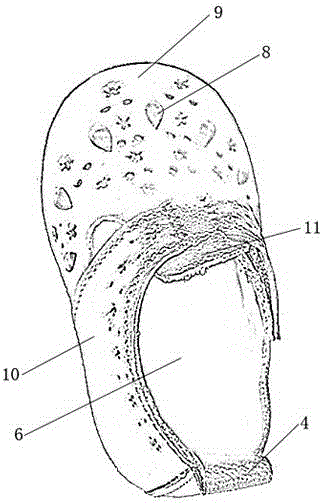

[0022] figure 1 , figure 2 As shown, the present invention includes the inner upper 7 of the sole 6 and the upper of the shoe 2 and the outer upper 2 and or the upper upper 9 of the shoe, and the upper upper 10 of the rear shoe 6, which are each curved portion of the close-fitting foot. High, said sole 6, inner upper 7, outer upper 2 or front upper 9, rear upper 10 are all made of a known leather material, sole 6 and inner upper 7, outer upper 2 and or front upper 9, rear upper The stitching between the upper of a shoe 10 is all stitching in the shoe, and the stitching between the sole 6 and the inner upper of a shoe 7, the outer upper of a shoe 2 and or the front upper of a shoe 9, and the rear upper of a shoe 10 is manual stitching, and can also be machine stitched.

[0023] Said inner upper of a shoe 7, outer upper of a shoe 2 rear sutures can also be set up heel bar 4, can increase the firmness of rear sutures.

[0024] Said inner upper of a shoe 7, outer upper of a sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com