Dosing system for gaseous materials

A batching system and gaseous material technology, applied in the direction of mixer accessories, gas and gas/steam mixing, dissolution, etc., can solve the problem of uneven material composition and content in the outflow container, improve control accuracy and control difficulty, and meet large materials The effect of leak rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

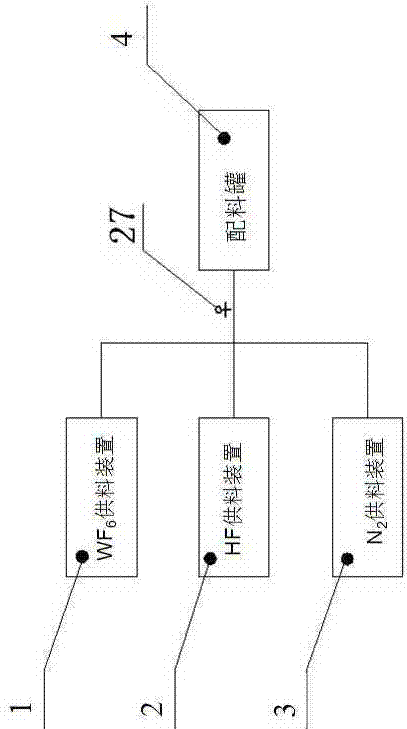

[0029] Such as figure 1 As shown, a batching system for gaseous materials, including WF 6 Feeding device 1, HF feeding device 2, N 2 The feeding device 3 is connected in parallel to the pipeline 6 and communicates with the batching tank 4 .

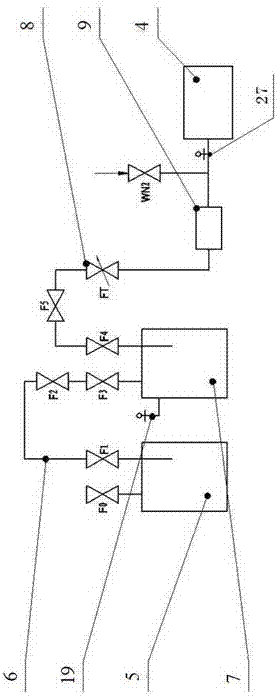

[0030] Such as figure 2 shown, the WF 6 Feed unit 1 includes WF 6 Feed container 5, WF 6 The first interface of the supply container 5 is provided with an F0 valve, WF 6 Feed container 5 with WF 6 The pipelines 6 between the surge tanks 7 are sequentially provided with F1-F3 valves, WF 6 The pipeline 6 between the surge tank 7 and the batching tank 4 is provided with F4 valve, F5 valve, manual fine-tuning valve 8, WF 6 Mass flow meter 9 and No. VII pressure gauge 27.

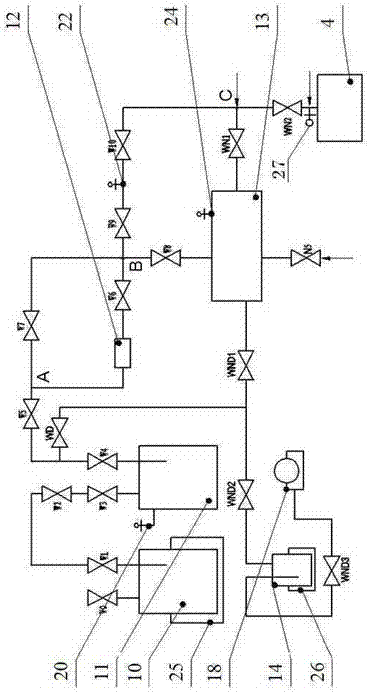

[0031] so image 3 As shown, the HF feeding device 2 described includes a HF feeding container 10, the first interface of the HF feeding container...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com