Pressure spot welding tooling and method for sunken type explosive-loading cavity sealing cap

A sealing cover and drug-carrying technology, used in welding equipment, manufacturing tools, laser welding equipment, etc., can solve the problems of human negligence and difficulty in positioning the sealing cover, so as to overcome welding difficulties and meet the requirements of leakage rate. , to ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

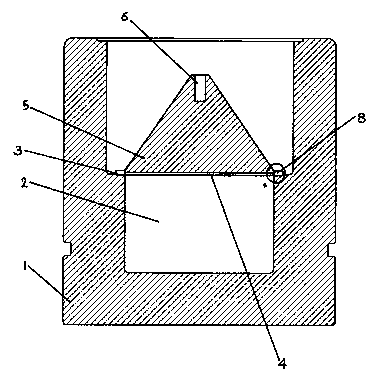

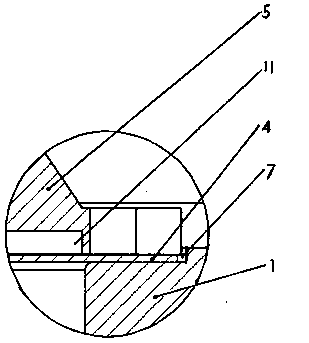

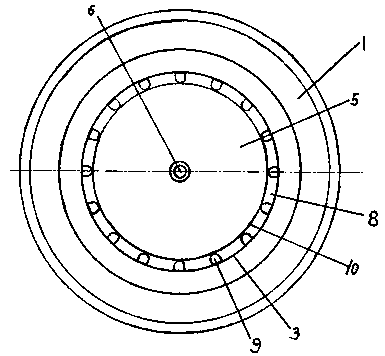

[0021] The present invention is described in detail below in conjunction with accompanying drawing:

[0022] A sinking type medicine-carrying chamber seal cover compression spot welding tool in a cartridge, comprising a cartridge 1, a sunken medicine-carrying chamber 2 is arranged in the cartridge 1, and a sunken medicine-carrying chamber 2 is arranged in the cartridge 1 Filled with black gunpowder, the upper port of the sinking drug chamber 2 is provided with a sealing cover installation step hole 3, and a sealing cover 4 is provided in the sealing cover installation step hole 3, and the thickness of the sealing cover 4 is only 0.2 mm. An annular gap 7 is formed between the sealing cover 4 and the step wall of the sealing cover installation step hole 3. When the annular gap 7 is a uniform gap, the positioning of the sealing cover 4 is accurate. If the positioning of the sealing cover 4 is inaccurate, pass 16 laser welding spot welding groove-shaped gaps 9 can be clearly obser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com