Workpiece undamaged washing machine and using method thereof

A technology for cleaning machines and workpieces, which is applied in the directions of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

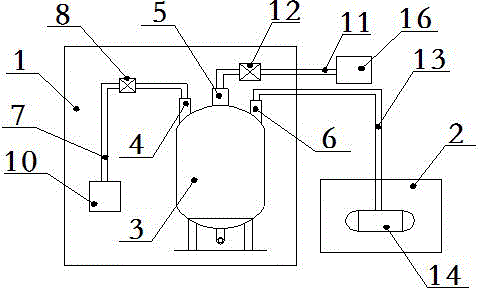

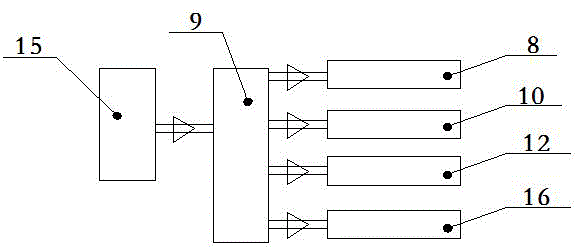

[0018] Such as figure 1 and figure 2 As shown, a workpiece non-destructive cleaning machine, it includes a cabinet 1 and a washing pool 2 matched with the cabinet 1, the inside of the cabinet 1 is provided with a pressure dissolving tank 3, and the upper part of the pressure dissolving tank 3 is provided There is an air inlet 4, a water inlet 5 and a water outlet 6, the air inlet 4 is connected to the air inlet pipe 7, the air inlet pipe 7 is provided with a valve A8, and the valve A8 is connected to the controller 9 through a signal line , the controller 9 is a programmable controller, the air inlet end of the air intake pipe 7 is connected with an air pump 10, the air pump 10 is arranged inside the cabinet 1, and the air pump 10 is connected with the controller 9 through a signal line, and the air pump 10 is connected to the controller 9 through a signal line. The water inlet 5 is connected with a water inlet pipe 11, and the water inlet pipe 11 is provided with a valve B1...

Embodiment 2

[0022] Such as figure 1 and figure 2 As shown, a workpiece non-destructive cleaning machine, it includes a cabinet 1 and a washing pool 2 matched with the cabinet 1, the inside of the cabinet 1 is provided with a pressure dissolving tank 3, and the upper part of the pressure dissolving tank 3 is provided There is an air inlet 4, a water inlet 5 and a water outlet 6, the air inlet 4 is connected to the air inlet pipe 7, the air inlet pipe 7 is provided with a valve A8, and the valve A8 is connected to the controller 9 through a signal line , the controller 9 is a programmable controller, the air inlet end of the air intake pipe 7 is connected with an air pump 10, the air pump 10 is arranged inside the cabinet 1, and the air pump 10 is connected with the controller 9 through a signal line, and the air pump 10 is connected to the controller 9 through a signal line. The water inlet 5 is connected with a water inlet pipe 11, and the water inlet pipe 11 is provided with a valve B1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com