Processing technology of hanging shaft of can presser

A processing technology and technology of pressing cans, which is applied in the field of processing technology of hanging shafts for pressing cans, can solve problems such as inability to guarantee product quality requirements, and achieve the effect of low cost and strong continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

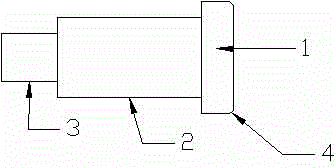

[0008] Below in conjunction with accompanying drawing, the present invention will be further described:

[0009] In the view, take the hanging shaft of the tank press as an example, choose ordinary carbon round steel and cut it to the required length, and then clamp it on the chuck of the instrument lathe - first, flush the round steel head with the car - car fixed shaft 3, car Revolving shaft 2, car stop plate 1, car chamfer 4-overall rotation and polishing-soaking to remove oil and rust-surface chrome plating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com