Device for preparing fuel by utilizing biomass catalysis and preparation method

A technology for catalytic preparation and biomass raw materials, applied in the field of biomass thermal conversion, can solve the problems of poor adaptability, different types and particle size requirements, etc., and achieve the effects of strong continuity, prolonged residence time and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

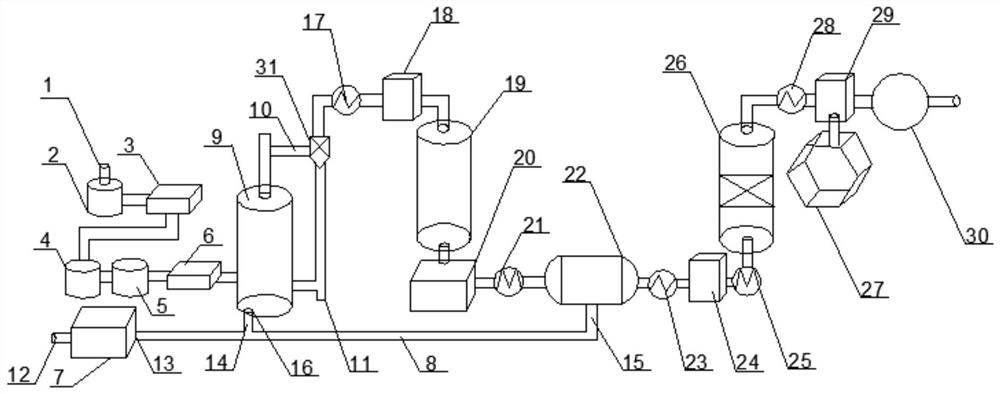

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] like figure 1 As shown, a device for preparing fuel using biomass catalysis includes a biomass raw material pretreatment system, a gasification system, a gasification product processing system and a synthesis system;

[0028] The biomass raw material pretreatment system includes a biomass raw material inlet 1, a water washing tank 1 2, a drying chamber 1 3, a pickling tank 4, a water washing tank 2 5 and a drying chamber 2 6, a biomass raw material inlet 1 and a water washing tank. The inlet end of one 2 is connected, the outlet end of washing tank one 2 is connected with the inlet end of drying chamber one 3, the outlet end of drying chamber one 3 is connected with the inlet end of pickling tank 4, and the outlet end of pickling tank 4 is connected with the water washing tank 4. The inlet end of the second tank 5 is connected, and the outlet end of the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com