Technical method of directly separating vanadium and chromium from sodium modification vanadium extraction waste water

A technique for extracting vanadium by sodium and a process method, which is applied in the field of direct separation of vanadium and chromium, which can solve the problems of long vanadium and chromium separation process, large production safety hazards, and large amount of impurity remover, so as to achieve strong continuity and reduce processing costs , the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

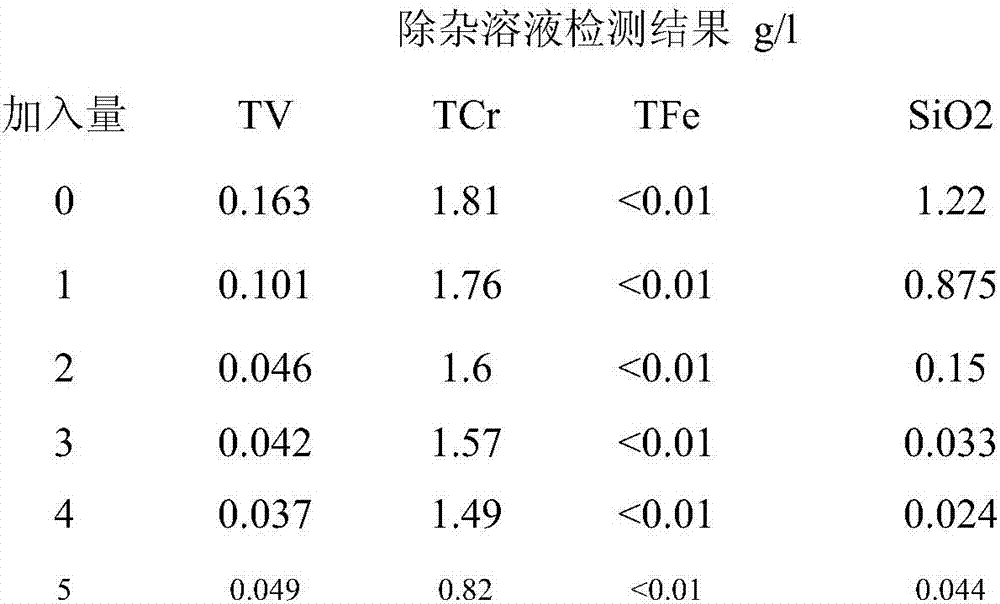

[0022] Addition test of impurity remover

[0023] In the laboratory, the test to determine the amount of impurity remover added was carried out, and the same amount was added to the test to detect the effect of impurity removal; the experimental results are as follows:

[0024]

[0025] According to the test results, it is determined that the optimal amount of impurity remover added is 4ml / l.

Embodiment 2

[0027] Determination of pH value of vanadium silicon precipitation

[0028] In the laboratory, vanadium and silicon precipitation tests were carried out under different pH conditions. The test results are as follows:

[0029]

[0030] The test results show that the optimal pH of vanadium-silicon co-precipitation is 4.5-5.

Embodiment 3

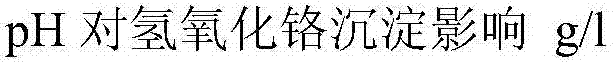

[0032] Determination of pH Value of Chromium Hydroxide Precipitation

[0033] In the laboratory, precipitation tests were carried out under different pH conditions; the test results are as follows:

[0034]

[0035]

[0036] The test results show that the optimum pH for chromium hydroxide precipitation is 7.5-8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com