Fixing structure for nail gun cartridge clip slotting

A technology of fixed structure and bullets, which is applied in the field of processing fixtures, can solve problems such as loose clip fixing, production rate drop, and clip shifting, and achieve the effects of improving production efficiency, product quality, convenient use, and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

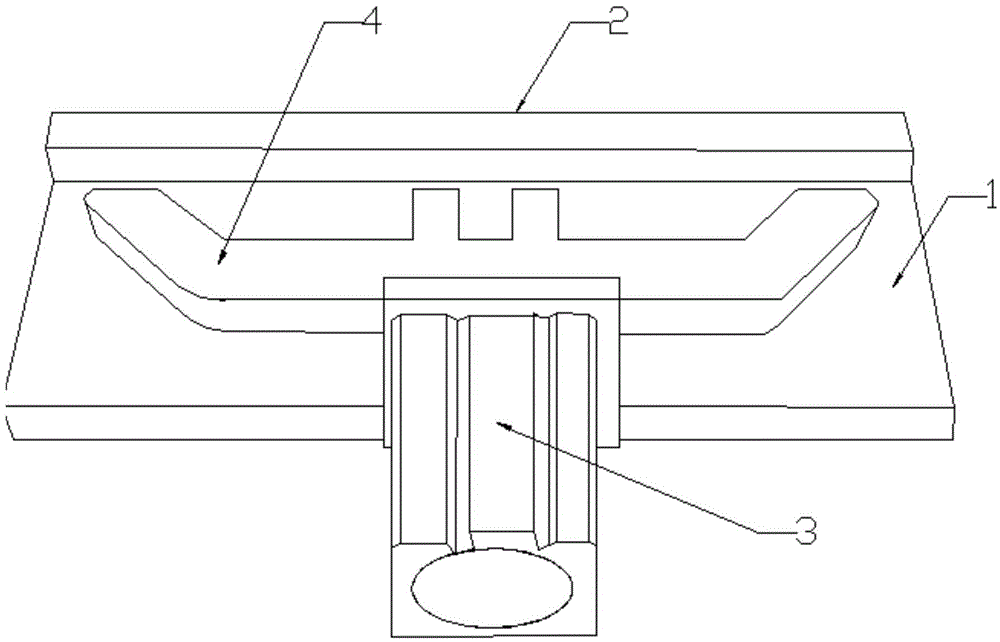

[0016] Such as figure 1 As shown, a nail gun magazine slotted fixing structure is characterized in that: a support plate 1 is provided, a baffle plate 2 is fixed on one side of the support plate 1, and a baffle plate 2 is fixed on the other side of the support plate 1 A cylinder 3 is installed, and a limit mechanism 4 is connected to the piston rod of the cylinder 3, the limit mechanism 4 is located between the baffle plate 2 and the cylinder 3, and the limit mechanism 4 includes a first limit portion, a second limit mechanism Two limiting parts and a connecting part, the connecting part is also fixedly connected with the piston rod of the cylinder 3, the first limiting part, the connecting part and the second limiting part are sequentially connected into a "C" shape structure, so The limiting mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com