A self-centering tensioning installation fixture for thin-walled ring gear

A technology for installing fixtures and thin-walled ring gears, which is applied in the direction of measuring devices, manufacturing tools, workpiece clamping devices, etc., can solve the problem of affecting the processing quality of thin-walled ring gears, easily deforming thin-walled ring gears, and detection errors of ring gear deformation and other issues, to improve clamping efficiency and detection accuracy, avoid concentric alignment steps, and ensure the effect of neutrality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

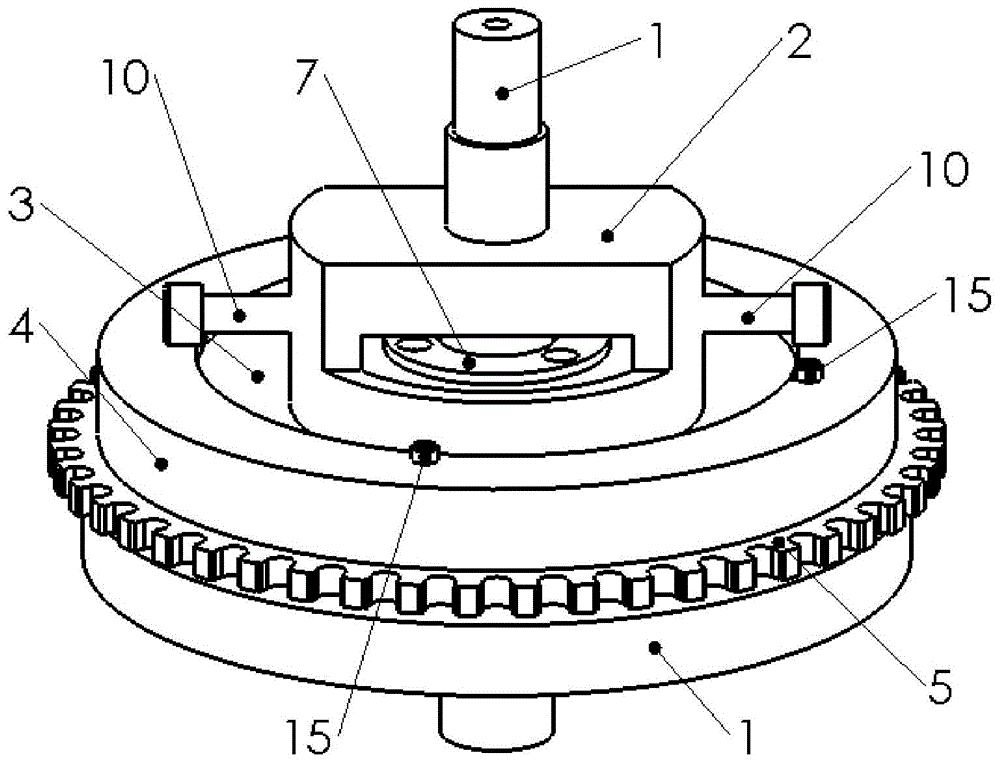

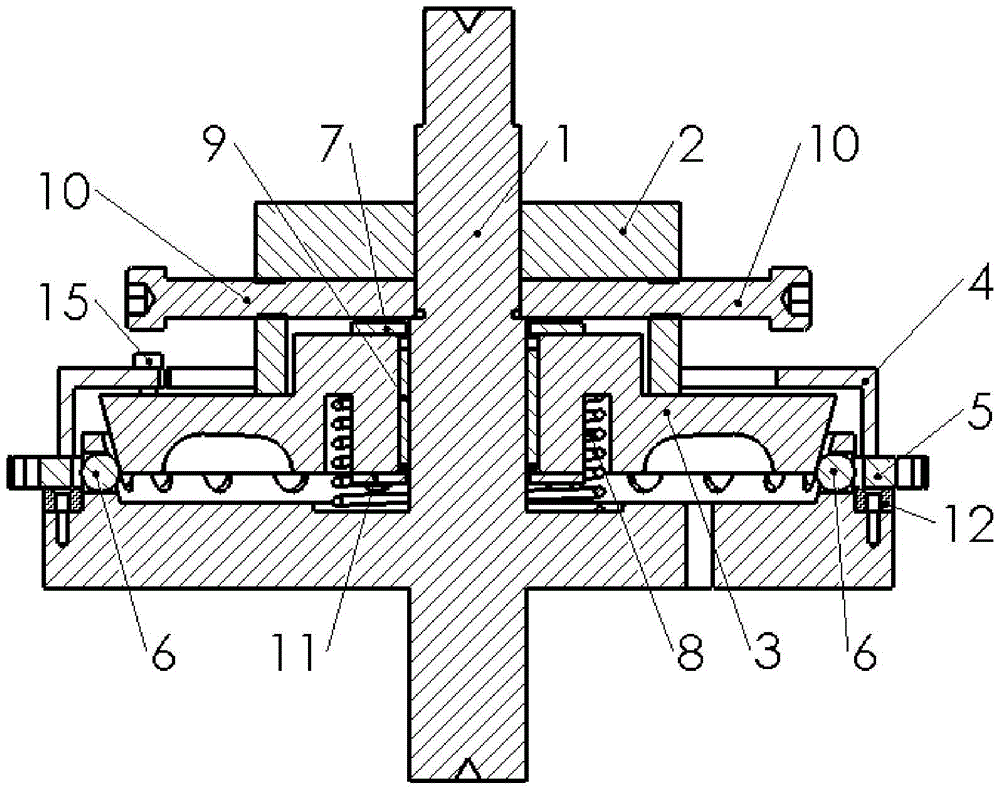

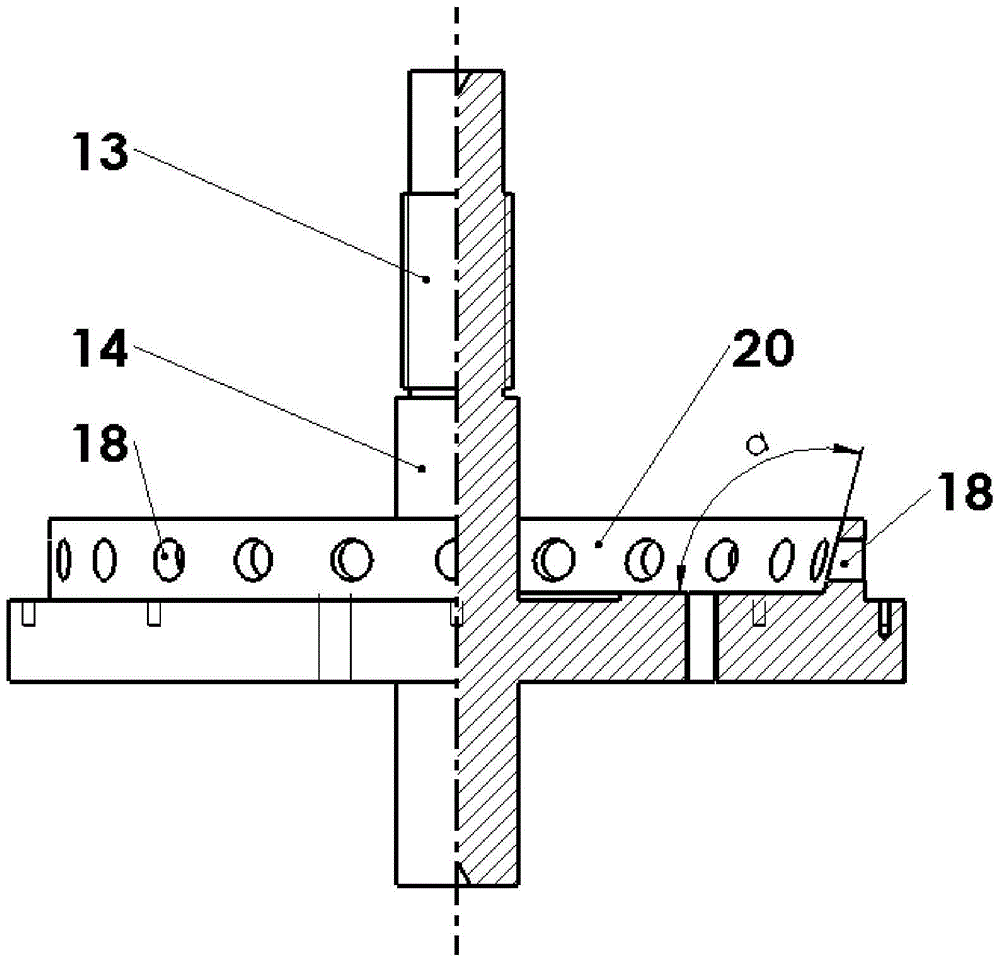

[0036] A self-centering tensioning installation fixture for thin-walled ring gear, see figure 1 , including mandrel base plate 1, compression plate 3, pressure ring 4, compression nut 2, dense ball bearing 9, upper cover 7, lower cover 11, tensioning steel ball 6, ring washer 12, top tight Bolt 10, spring 8, the pressure plate 3 is set on the mandrel base plate 1 through the spring 8, and the dense ball bearing 9 is set between the mandrel precision shaft section 14 on the mandrel base plate 1 and the pressure plate 3 , the upper cover 7 and the lower cover 11 are placed on the compression plate 3, the pressure ring 4 is set on the compression plate 3 and pressed against the thin-walled ring gear under test, the compression nut 2 passes through the thread and the mandrel The mandrel threaded shaft section 13 on the base plate 1 is connected and pressed on the pressure plate 3, the ring washer 12 is arranged on the mandrel base plate 1, and is used to support the thin-walled ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com