Device for separating film on material tape

A separation device and material belt technology, which can be applied to layered products, lamination auxiliary operations, lamination, etc., can solve the problems of affecting production efficiency, inconvenience, time-consuming and laborious, etc., and achieve the effect of improving production efficiency and improving success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

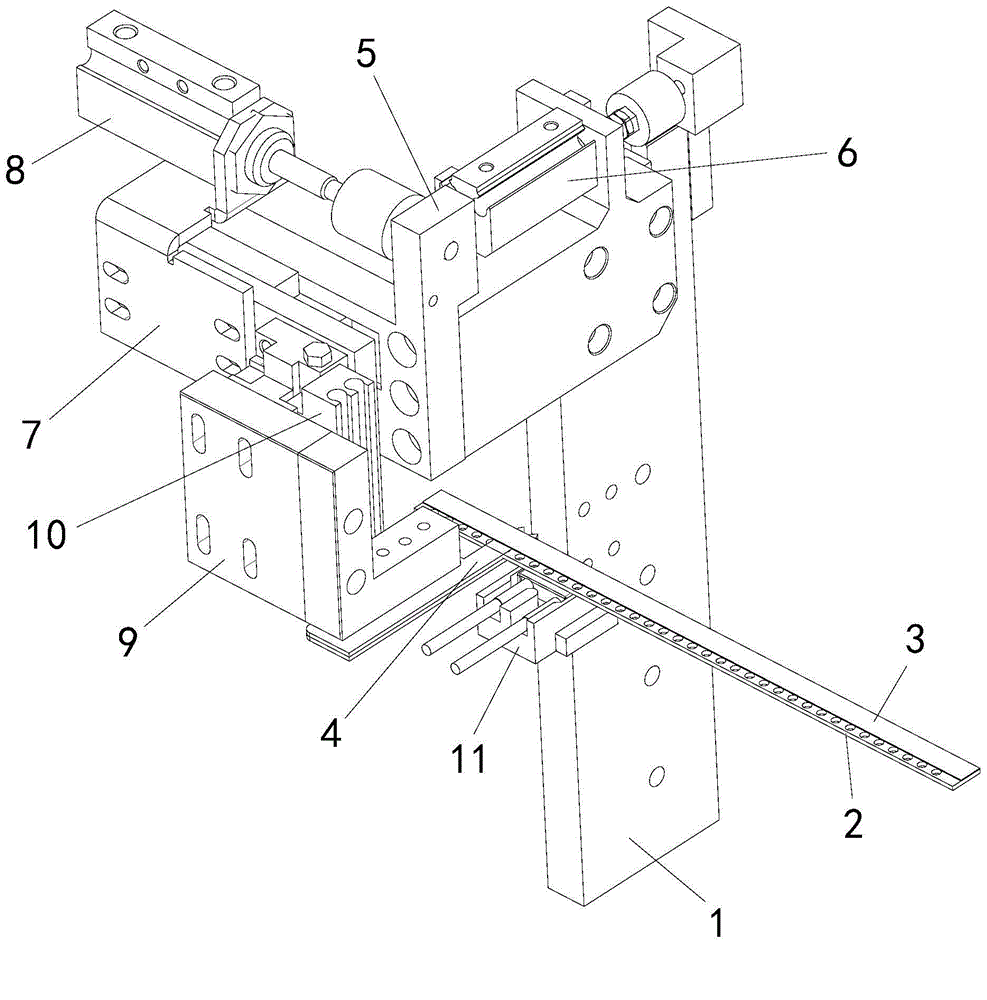

[0015] from the attached figure 1 It can be seen from the schematic diagram of the structure that this embodiment provides a material tape coating separation device, which includes a frame 1 and a support platform connected to the frame 1 for placing the material tape 2 (not shown in the accompanying drawings). ), a stripper 4 movably arranged on the frame 1 , a driving device for driving the stripper 4 to move, and the frame 1 is also provided with a heating device 11 for heating the material tape 2 . The material tape coating separation device of the present invention, by moving the peeler 4, presses it on the material tape 2 and inserts it between the material tape 2 and the film 3, so as to peel off the film 3, and by heating the material tape 2 (and covering the film 3) The film 3) on the top can be more convenient and stable to facilitate the insertion of the peeler 4.

[0016] The stripper 4 in this embodiment is a thin blade.

[0017] The frame 1 is provided w...

Embodiment 2

[0028] The only difference between this embodiment and the first embodiment is that the supporting platform is arranged on the bracket 1 so as to be movable left and right, and the bracket 1 is further provided with a fourth driving device for driving the supporting platform to move.

[0029] The working steps of the material tape coating separation device in this embodiment:

[0030] Steps 1-4 are the same as in Embodiment 1;

[0031] Step 5. After the stripper 4 is inserted between the material belt 2 and the film 3, the support platform is moved along the length direction of the material belt 2 by moving the support platform, so that the material belt 2 and the film 3 are separated.

Embodiment 3

[0033] The only difference between this embodiment and the second embodiment is that the stripper 4 is fixedly connected to the third connecting frame 9 , and the third connecting frame 9 is directly connected to the first connecting frame 5 so as to be movable up and down. The third driving device 10 is arranged on the first connecting frame 5 .

[0034] The working steps of the material tape coating separation device in this embodiment:

[0035] Step 1. Position the stripper 4 at the initial position at the start of the work by moving the first connecting frame 5;

[0036] Steps 2-5 are the same as the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com