A powertrain layout form of an electric vehicle

A technology of power assembly and form, applied in the direction of electric power device, power device, control device, etc., can solve the problems of vibration, noise pollution, complicated process, etc., and achieve the effect of reducing the number of parts and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

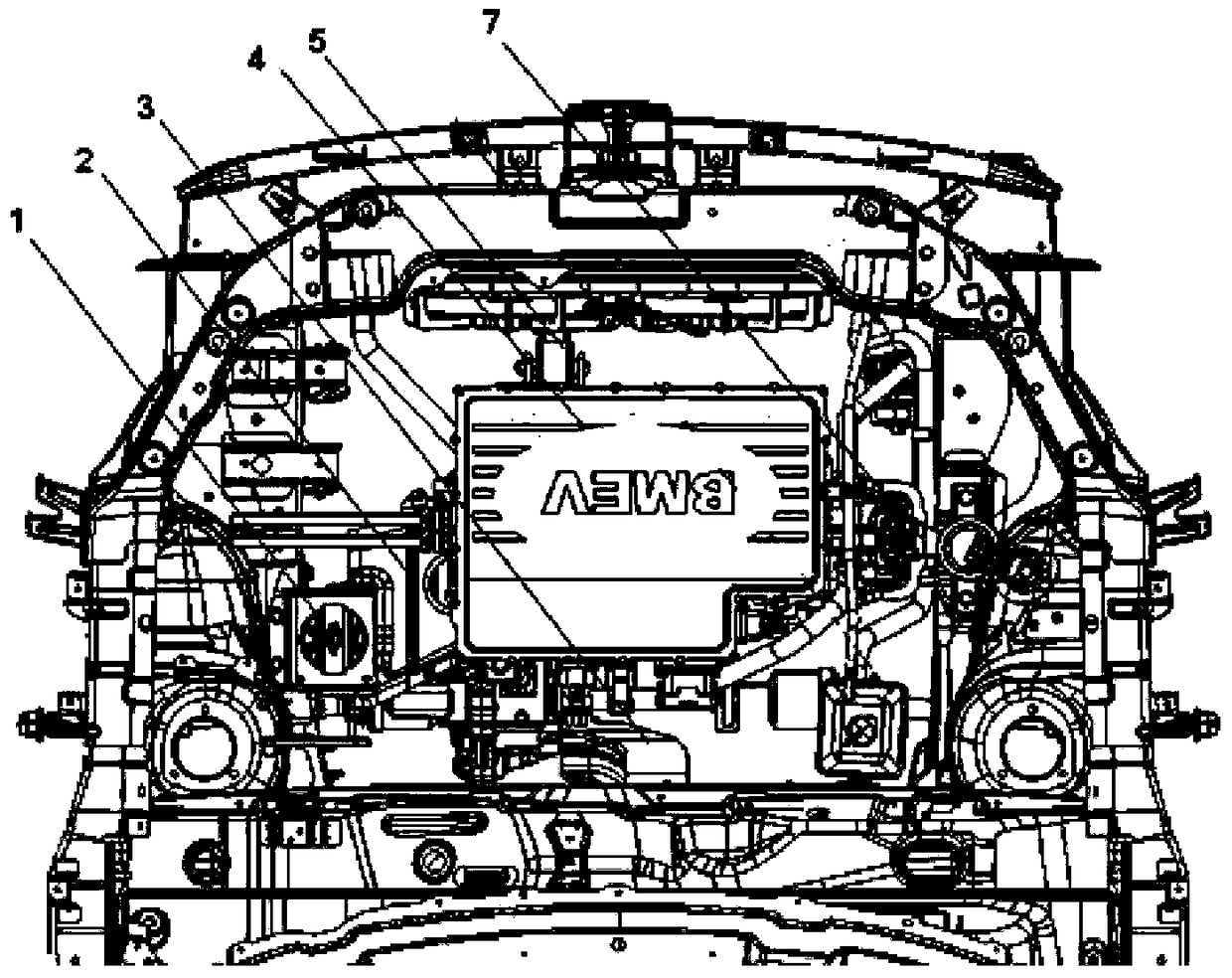

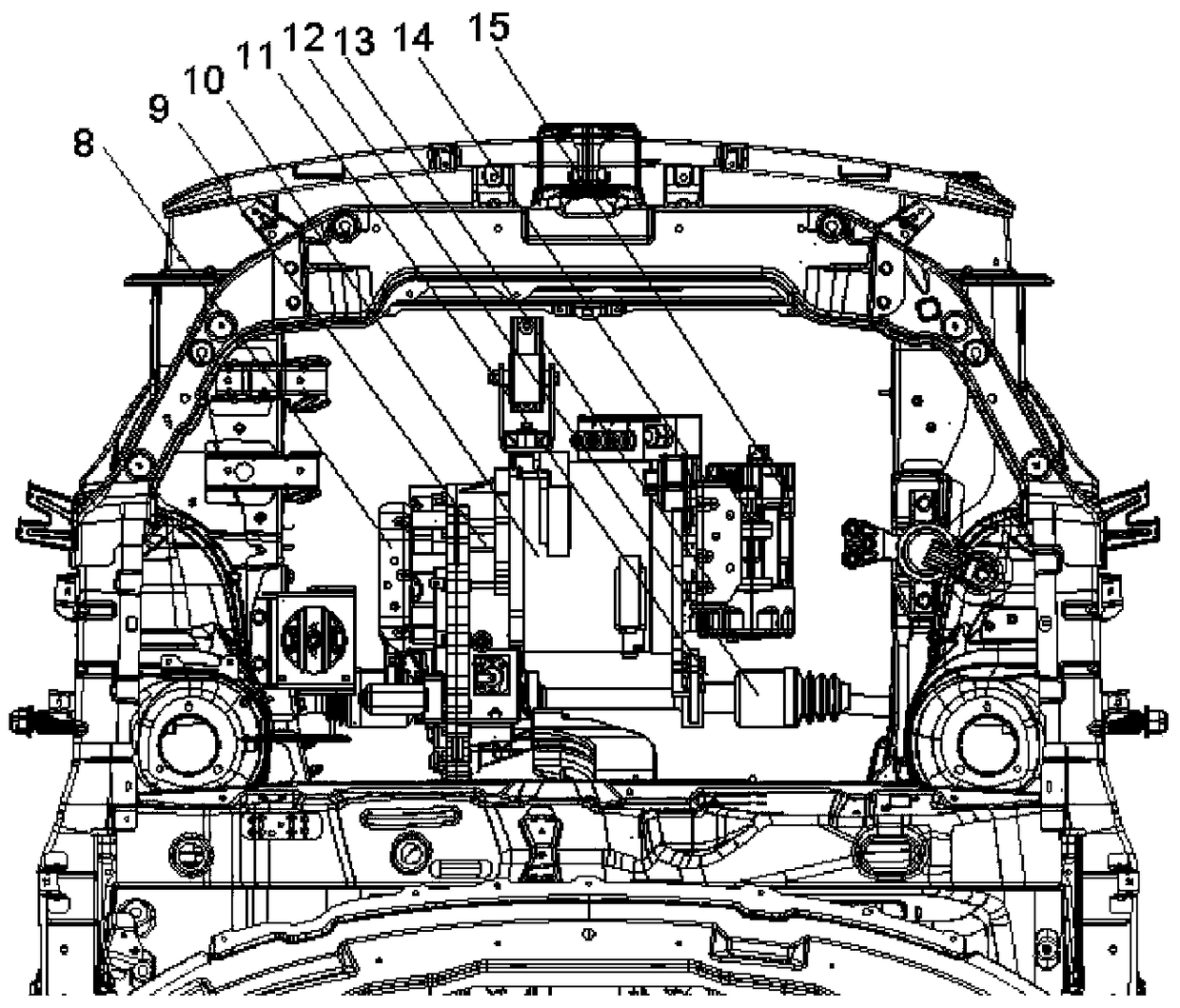

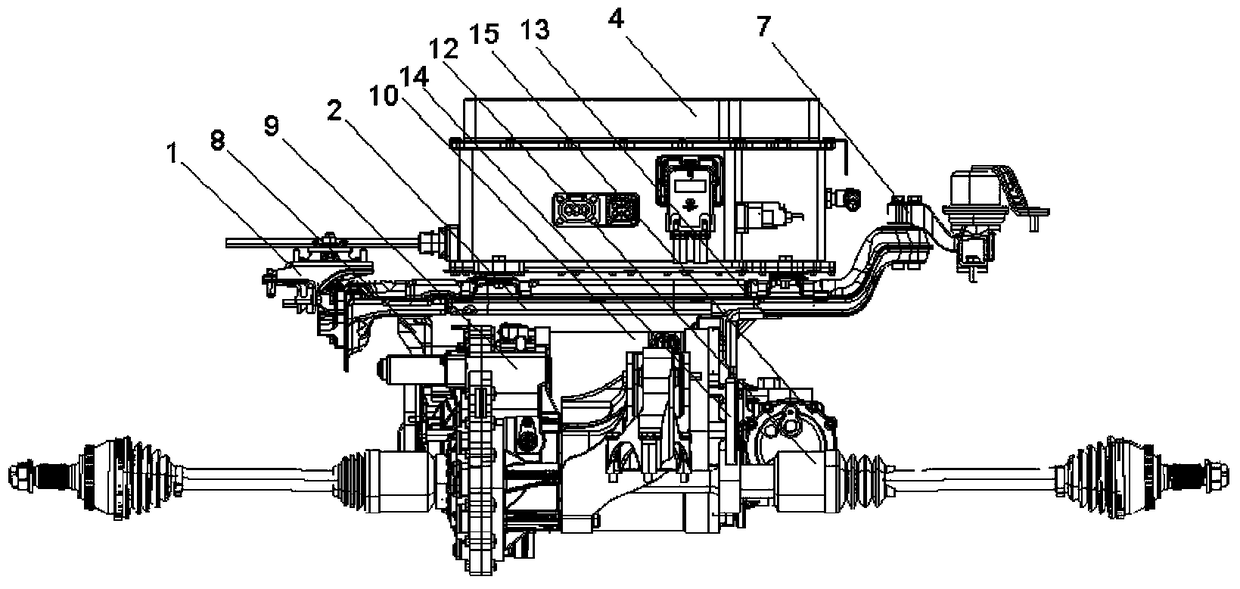

[0018] Embodiment 1: as Figure 1 to Figure 3 As shown, the present embodiment provides a powertrain layout form of an electric vehicle. The powertrain is provided in the front cabin, and the powertrain includes a left mount 1, a front cabin beam 2, a rear mount 3, an integrated controller 4, Front mount 5, right mount 7, reducer installation transition bracket 8, reducer 9, drive motor 10, transmission shaft support 11, drive shaft 12, drive motor installation transition bracket 13, compressor installation bracket 14 and air conditioner compressor 15. The front cabin beam 2 is fixed in the center of the front cabin by the left suspension 1 and the right suspension 7. The first end of the left suspension 1 is connected to the left end of the front cabin beam 2 by bolts, and the first end of the left suspension 1 The two ends are connected to the left longitudinal beam provided in the front cabin; the first end of the right suspension 7 is connected to the right end of the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com