Protective device for vehicle transmission shaft

A protection device and transmission shaft technology, applied in control devices, vehicle parts, transportation and packaging, etc., can solve the problems of reducing the shaking amplitude of the transmission shaft, the shaking of the transmission shaft, etc., to improve the safety performance, realize fixing and disassembly, prevent mopping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

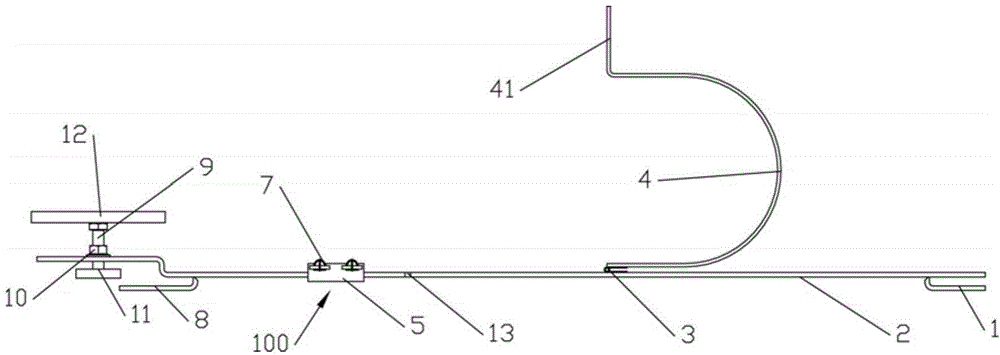

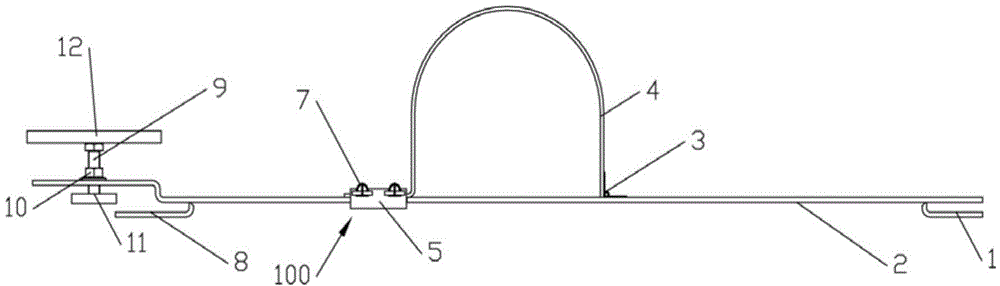

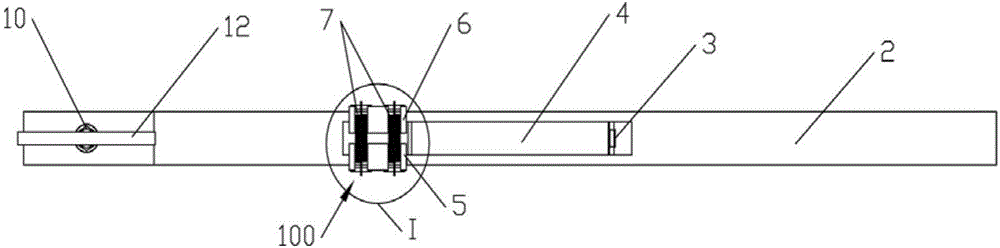

[0041] Such as Figures 1 to 6 As shown, the present invention is used for the protective device of the propeller shaft of vehicle, and it comprises: protective beam 2 and protective ring 4, and the two ends of protective beam 2 are respectively provided with the first connection part that is used for detachable connection with the vehicle frame of vehicle and the second connection part. Preferably, the first connecting part includes a first U-shaped groove 1 fixed at the end of the protective beam 2 and opening outward, and the second fixing part includes a second U-shaped groove 1 fixed at the end of the protective beam 2 and opening outward. The slot 8, the first U-shaped slot 1 and the second U-shaped slot 8 are respectively used to engage with the beam of the vehicle frame. The protective ring 4 is provided with an opening, and the protective ring 4 is preferably a U-shaped, oval or circular steel ring, and the size of the protective ring 4 is adapted to the transmission...

Embodiment 2

[0048] Embodiment 2 is basically the same as Embodiment 1, except that the insertion slot 100 is replaced by an integrated bushing with a cross-section of a zigzag shape, and the insertion slot 100 of the integrated sleeve is not provided with a locking portion 14 . During use, the slot 100 is slid to be connected to the plug board 41, lacking the locking function of the locking part 14 and the locking slot 13, and compared with Embodiment 1, the slot cannot be prevented from being locked during use. move.

Embodiment 3

[0050] This embodiment is basically the same as Embodiments 1 and 2, except that the first connecting portion and the second connecting portion at both ends of the protection beam 2 are detachably connected to the longitudinal beam of the vehicle frame by fasteners. During use, the two ends of the protection beam are clamped to the longitudinal beam of the vehicle frame through fasteners, and the protection ring is rotated to fix the position of the transmission shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com