A method of near-shore oil transportation for a non-dock tanker

An oil tanker and oil transportation technology, applied in transportation and packaging, ships, cargo handling equipment, etc., can solve the problems of a large number of infrastructure construction work, limited oil tanker handling, large initial investment, etc., to prevent leakage and recovery, improve handling efficiency, The effect of convenient oil delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

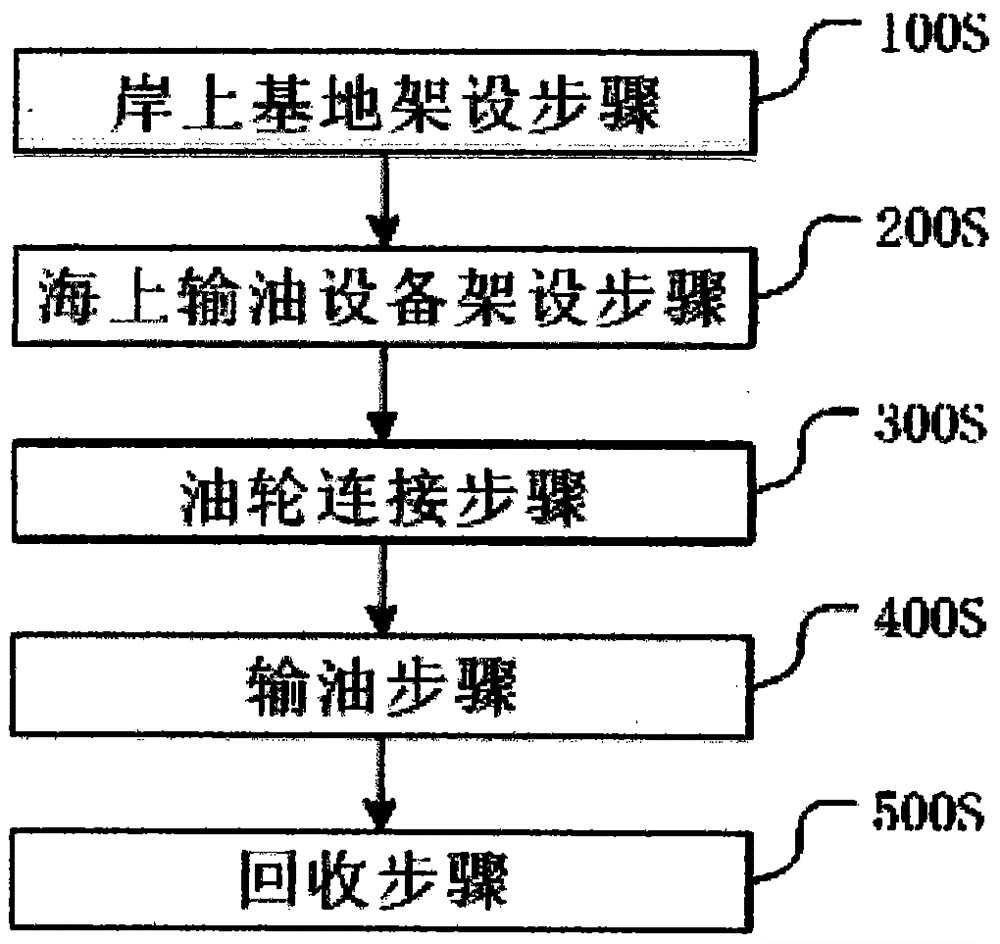

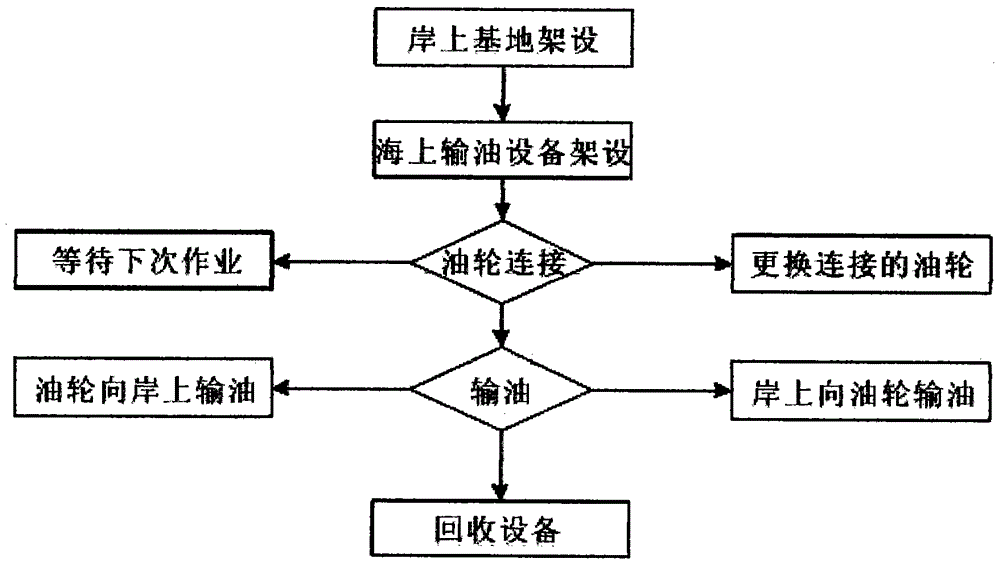

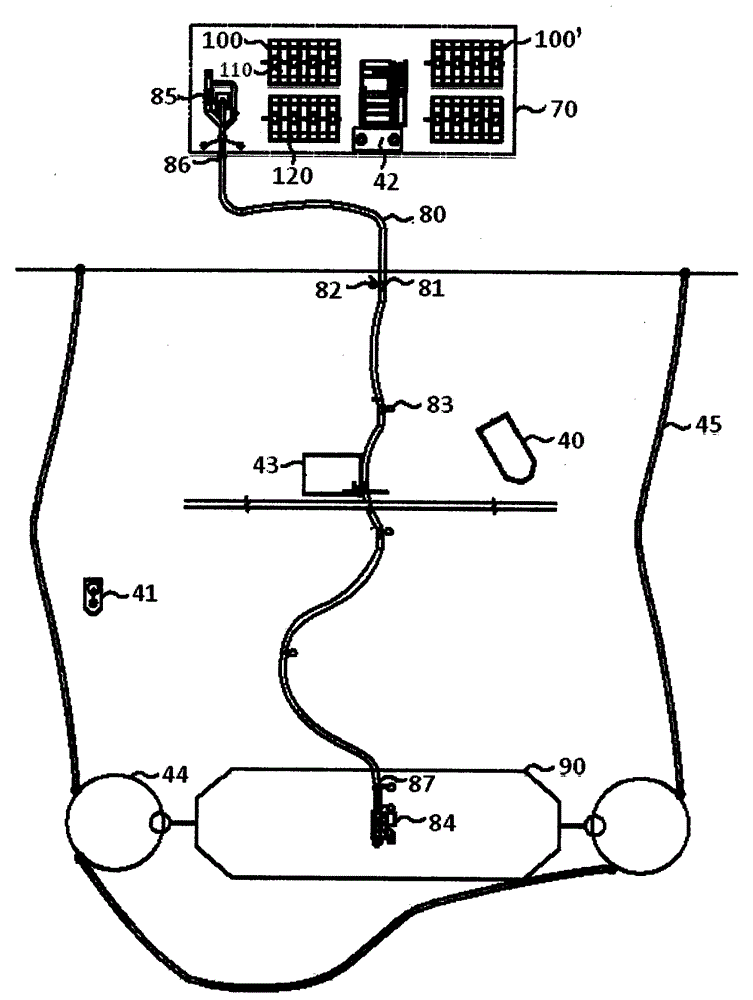

[0034] Such as figure 1 , 2 , 3, the dockless tanker nearshore oil delivery method of the present invention first establishes a temporary oil delivery base on the shore, and then connects with the offshore tanker 90 through the oil pipeline 80, and then realizes nearshore tanker oil delivery operations without docks at any time. Specific steps are as follows:

[0035] Onshore base erection step 100S: This step is used to provide onshore oil pipelines and power, including the installation of the retractable device 100 for retracting and unwinding the oil pipeline 80 and the installation of power equipment for powering the oil transportation process.

[0036] Through this step, the installation of equipment required for onshore oil transportation operations is realized. Wherein the retracting device 100 can be a complete set of equipment that can be used independently to control the automatic retraction of the oil delivery pipe 80, and can also be a manually operated device th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com