Fully symmetrical cable-membrane anti-hanging structure synchronous rotary sealing system

A technology of synchronous rotation and sealing system, which is applied to waterway systems, drainage structures, base frames, etc., can solve the problems of easy corrosion of internal steel structures, increased costs, and the self-heavyness of sealing covers, so as to achieve reliable processing quality and reduce site costs Occupancy and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

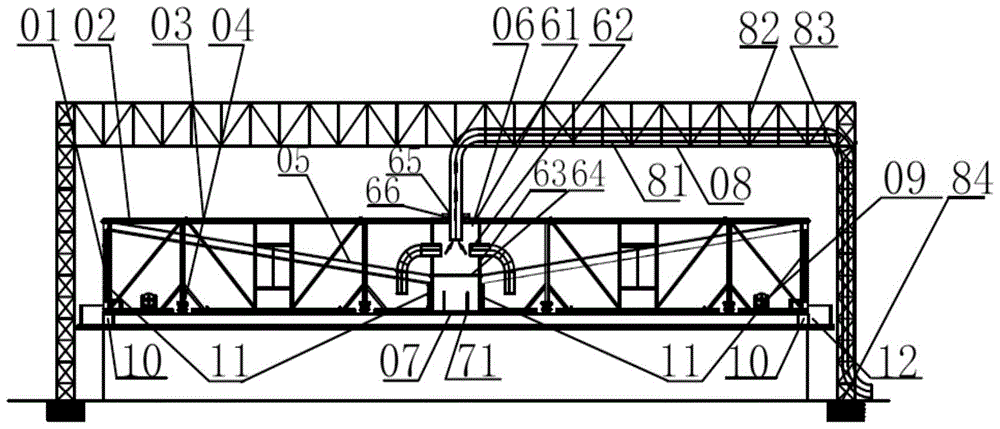

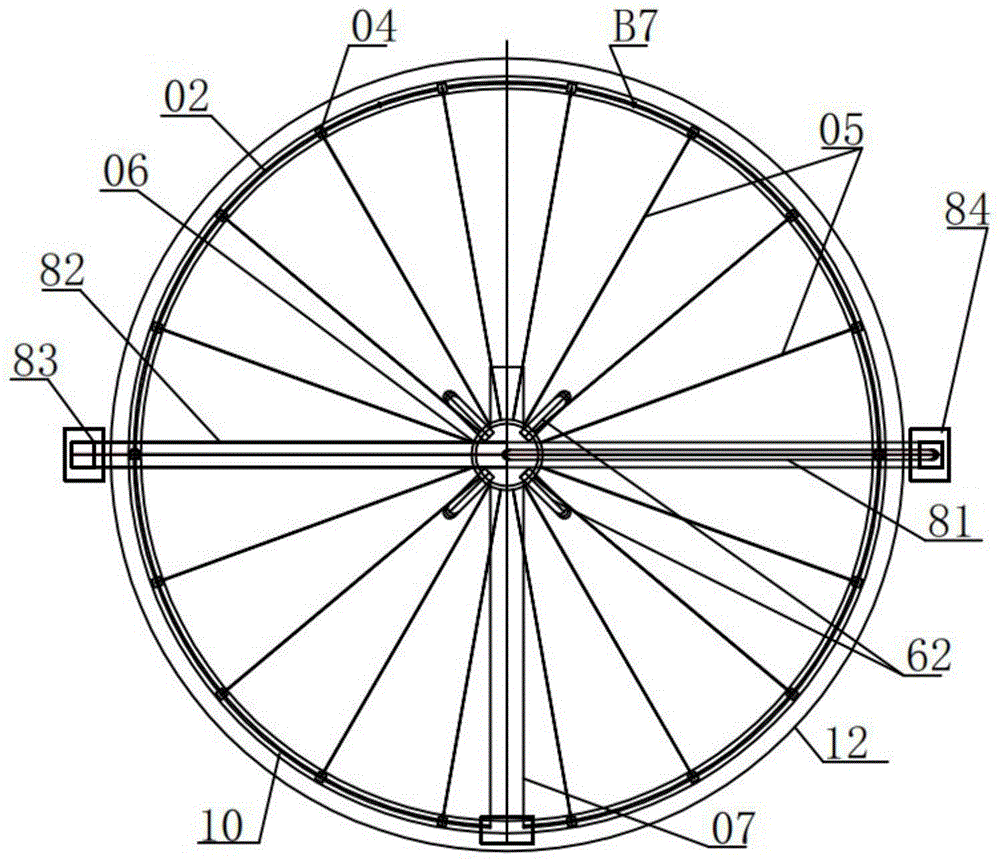

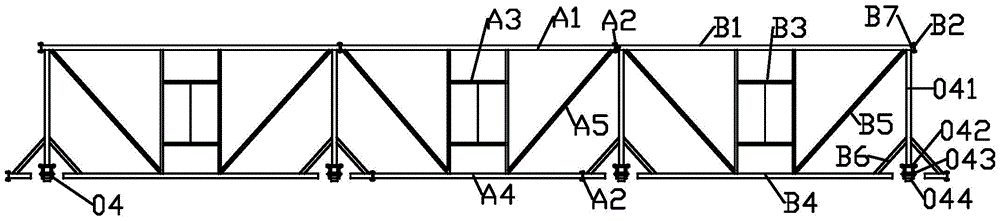

[0038] The following is a further detailed description of the fully symmetrical cable-membrane anti-hanging structure synchronous rotation sealing system of the present invention in conjunction with the accompanying drawings.

[0039] The fully symmetrical cable-membrane anti-hanging structure synchronously rotating sealing system of the present invention includes an annular track beam, a sealing cover, a universally adjustable load-bearing wheel device, a fully symmetrical dynamic sealing central gas collection device, and an intermediate air extraction pipeline through which the intermediate air extraction pipeline passes The bracket is fixed outside the sealing cover, the universally adjustable load-bearing wheel device is fixed on the ring track beam, the sealing cover is fixedly connected with the ring track beam through the sealing cover frame of a fully symmetrical structure, and the sealing cover and the ring track beam are in the same circle The mud scraper in the shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com