Column-by-column anti-freezing cooling unit capable of realizing air-side flow self-equalizing for indirect cooling tower

A cooling unit and self-flow technology, applied in refrigeration plants, industrial buildings, etc., can solve the problems of rising water temperature of cooling column 9, unbalanced water temperature of cooling column, weakening cooling performance of cooling triangle, etc. Local supercooling leads to freezing, improving overall cooling performance, and the effect of improving overall cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

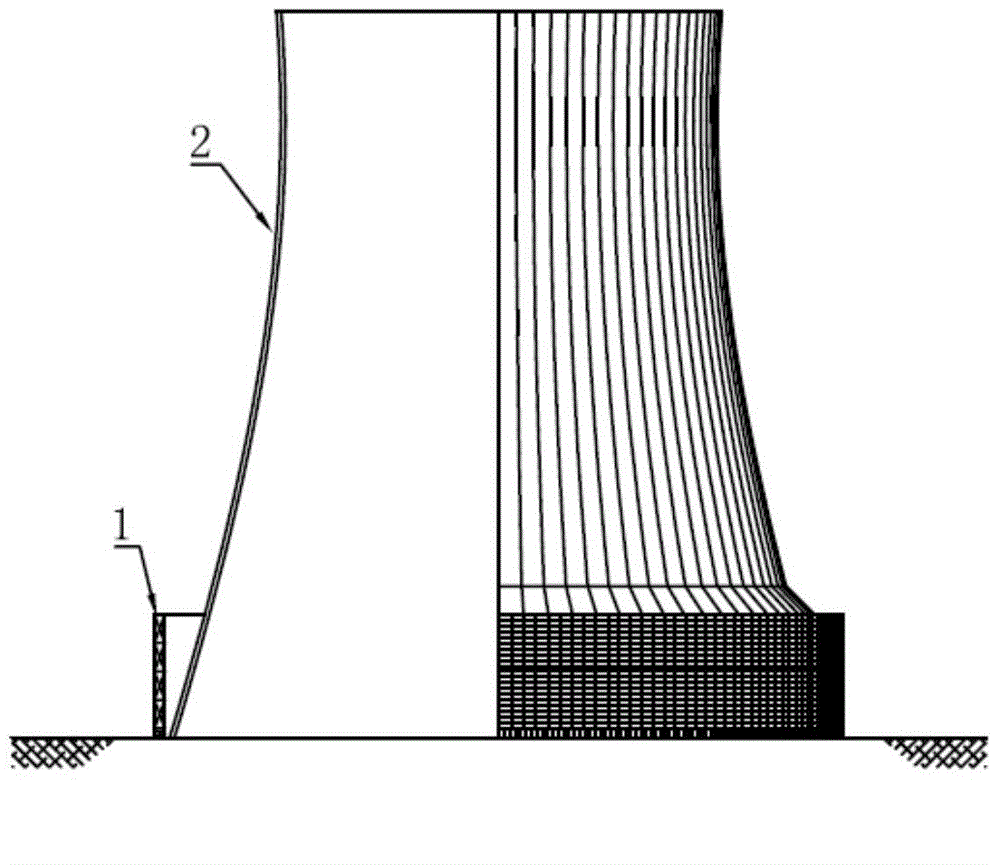

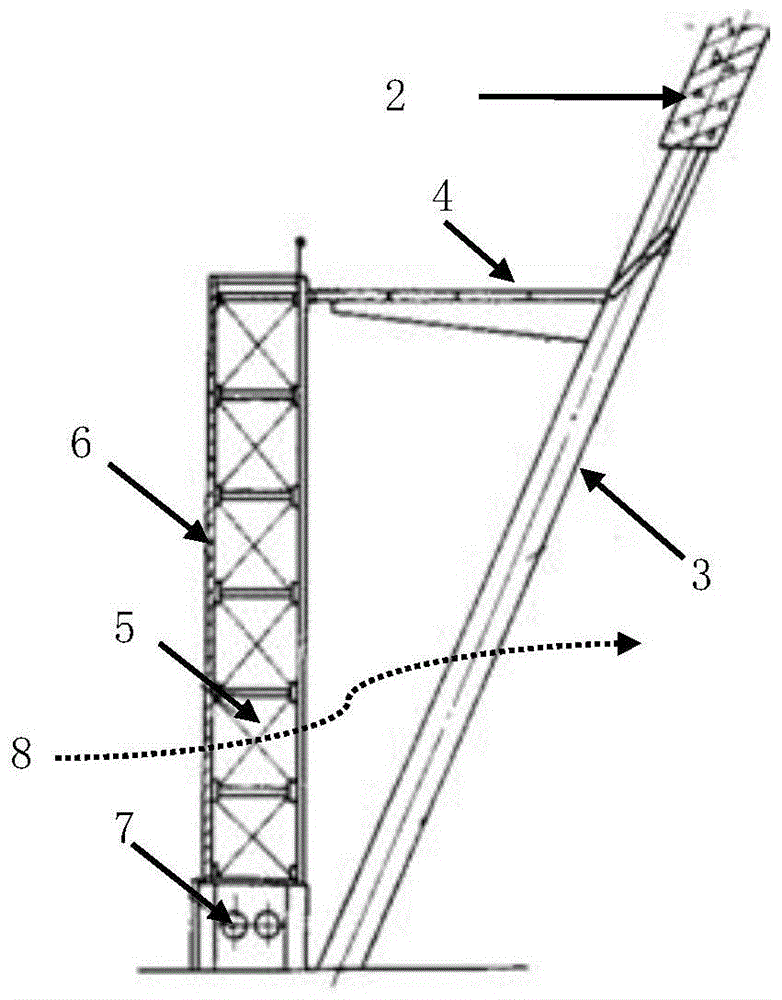

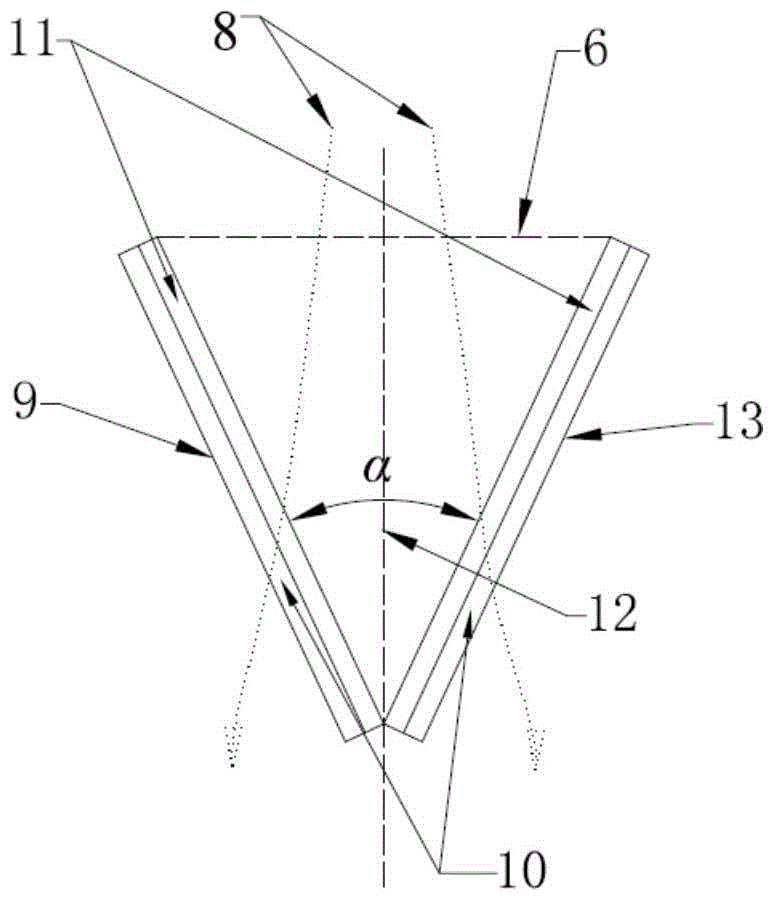

[0045] Such as figure 1 As shown, outside the tower shell 2 of the intercooling tower, a triangular cooling unit 1 is vertically arranged outside the air inlet of the intercooling tower. Such as figure 2 As shown, it is a schematic diagram of the longitudinal projection of the triangular cooling unit of the existing intercooling tower. Depend on figure 2 It can be seen that the triangular cooling unit is vertically arranged on the outer side of the pillar 3 and the sealing plate 4 of the intercooling tower, and is composed of a heat dissipation cooling column 5 and an air intake louver 6, wherein the air intake louver 6 is a plate structure and is horizontally arranged on the heat dissipation cooling column. 5; the circulating water enters the upper water side tube bundle of the cooling column from the water pipe 7 below the cooling column and then flows out through the lower water side tube bundle, while the ambient air 8 sweeps across the heat dissipation tube bundle to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com