Integral top beam combined suspension hydraulic support of moving frame with pressure and method of moving frame with pressure

A technology of moving racks with pressure and hydraulic supports, which is applied to mine roof supports, earthwork drilling, mining equipment, etc. It can solve the problems of occupying limited space of equipment, unsatisfactory results, and broken roofs, so as to reduce the probability of broken roofs, The effect of reducing repeated unloading and improving safety production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with embodiment the present invention is further described.

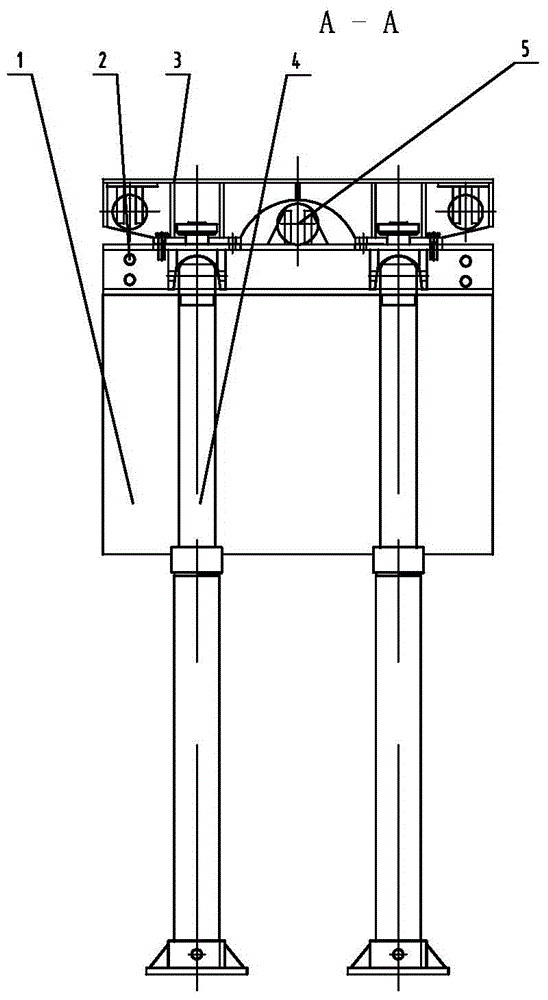

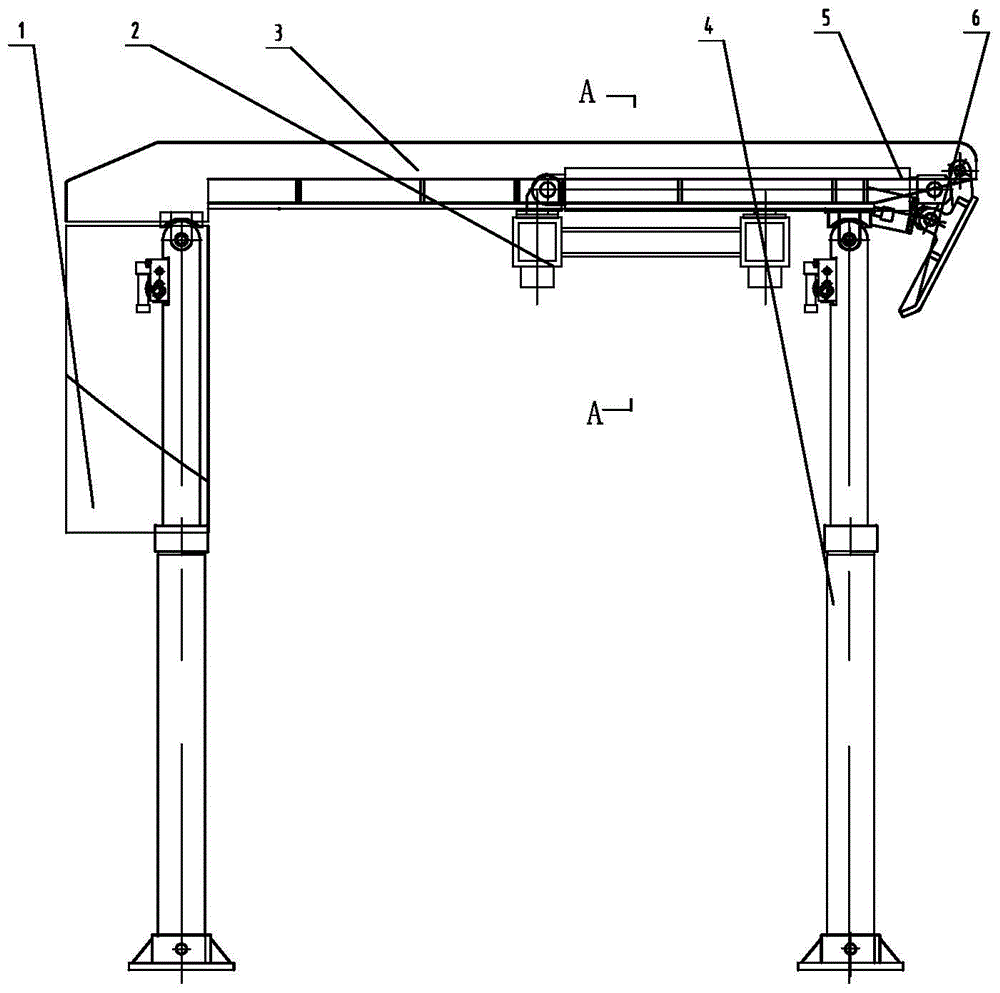

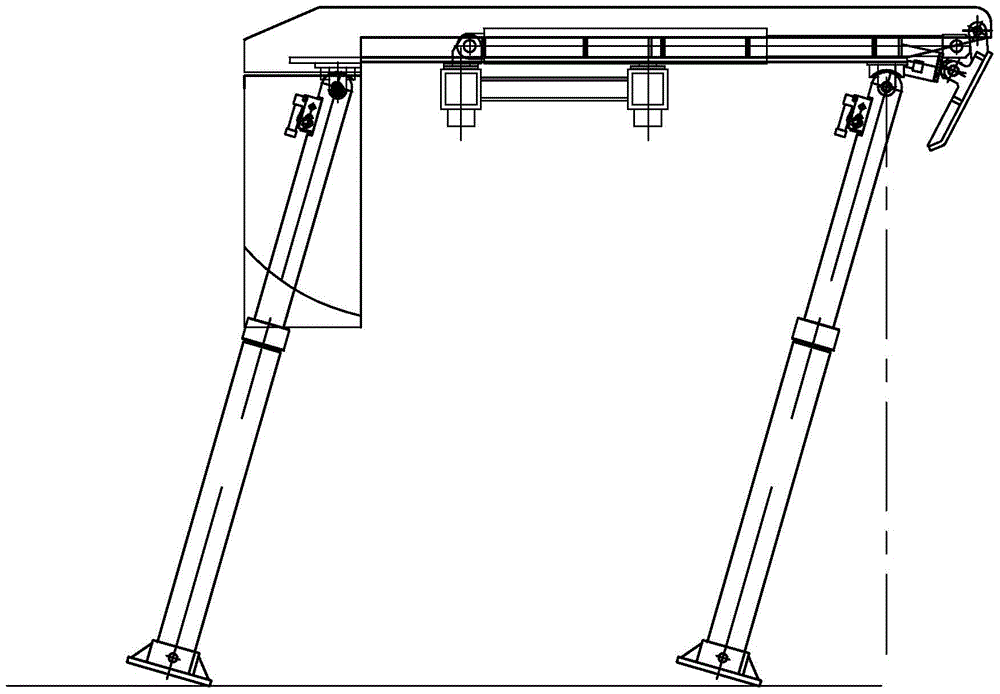

[0030] Such as figure 1 , such as 2, image 3 Shown is a combined suspension hydraulic support with a pressure-shifting frame and an integral top beam, which includes a joist 2, a top beam 3, a hydraulic column 4 and a top beam jack 5, and the lower end of the top beam 3 is hinged to four hydraulic Column 4, one end of the moving beam jack 5 is hinged to the joist 2, the other end of the moving beam jack 5 is hinged to the front end of the top beam 3, and a jacking beam is installed between the joist 2 and the top beam 3 3. A guiding mechanism for front and rear guide sliding is made on the joist 2, and the gap between the joist 2 and the top beam 3 can float up and down within a certain range. The adjacent hydraulic supports on both sides are hinged into one body by respective joists 2 . The hydraulic control system of the four hydraulic columns 4 includes: a high-pressure liquid supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com