Globe joint cardan

A universal joint and ball joint technology, applied in elastic couplings, mechanical equipment, couplings, etc., can solve the problems that the universal joint cannot be miniaturized and cannot meet the requirements of small space transmission, and achieves a small solution. Space transmission requirements and the effect of ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

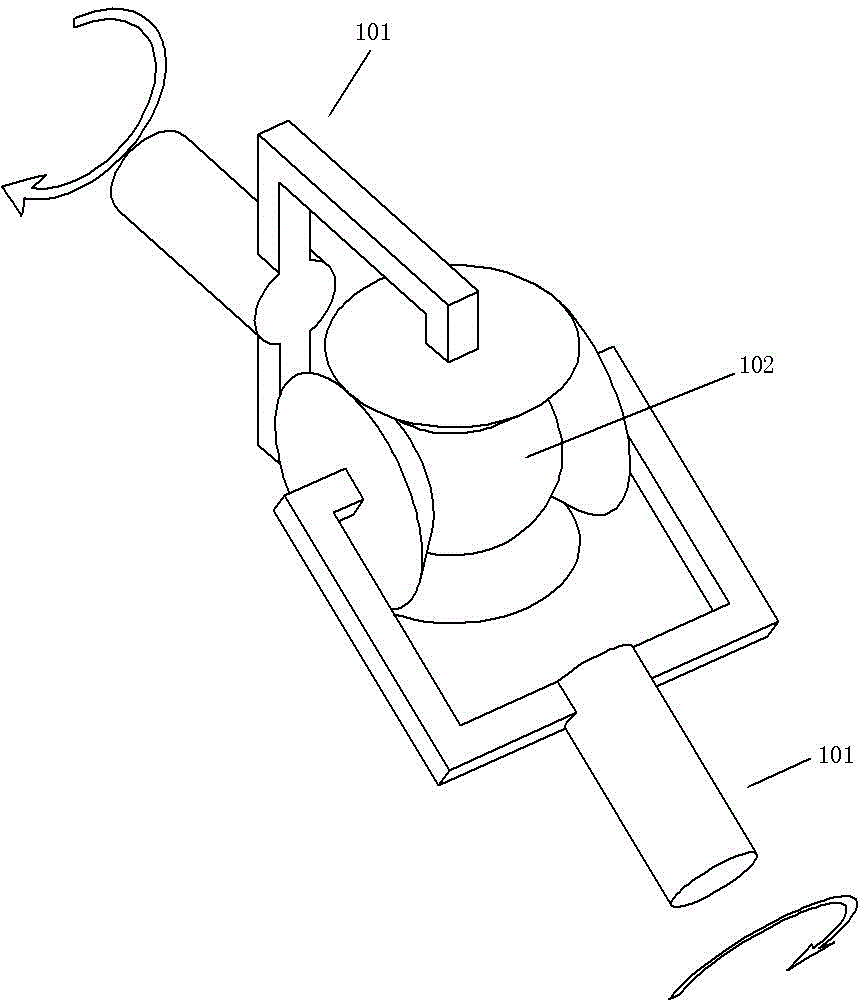

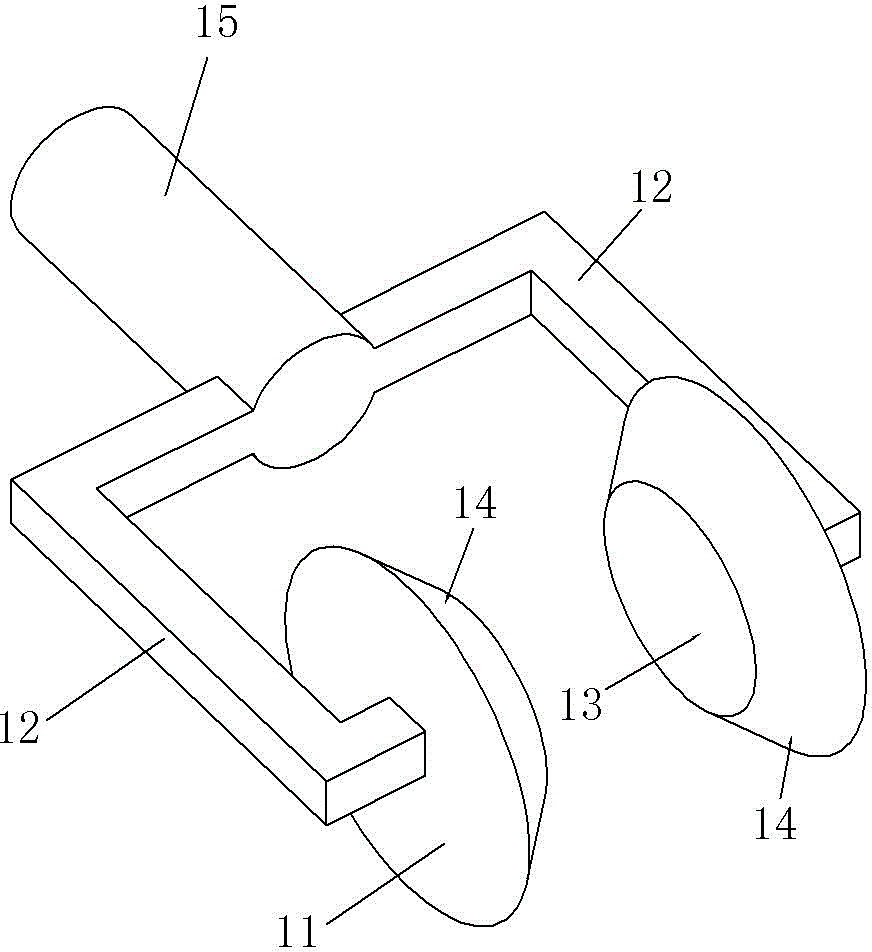

[0016] Examples of ball joints such as Figure 1-2 As shown, the ball joint universal joint includes a universal joint yoke 101 and a joint ball 102 .

[0017] There are two universal joint forks 101, and the two universal joint forks 101 have the same structure, so only the structure of one universal joint fork is introduced here. In this embodiment, the universal joint yoke 101 adopts a one-piece structure, which includes a fork head and a clamping plate 11 oppositely arranged. On the yoke 12 of the fork, the inner side of the clamping plate 11 is provided with a ball socket 13 corresponding to the joint ball 102 and a conical revolving surface 14. The conical shape formed by the revolving surface 14 gradually becomes larger from the inside of the clamping plate 11 to the outside, and the joint ball 102 is clamped between the clamping plates of two universal joint forks, and the rotary surfaces of the adjacent clamping plates of the two universal joint forks are tangentiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com