Slide valve

A sliding valve and spool technology, applied in sliding valves, multi-way valves, valve devices, etc., can solve the problems of rising material costs and manufacturing costs, and achieve the effect of simple structure and restraining the rise of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

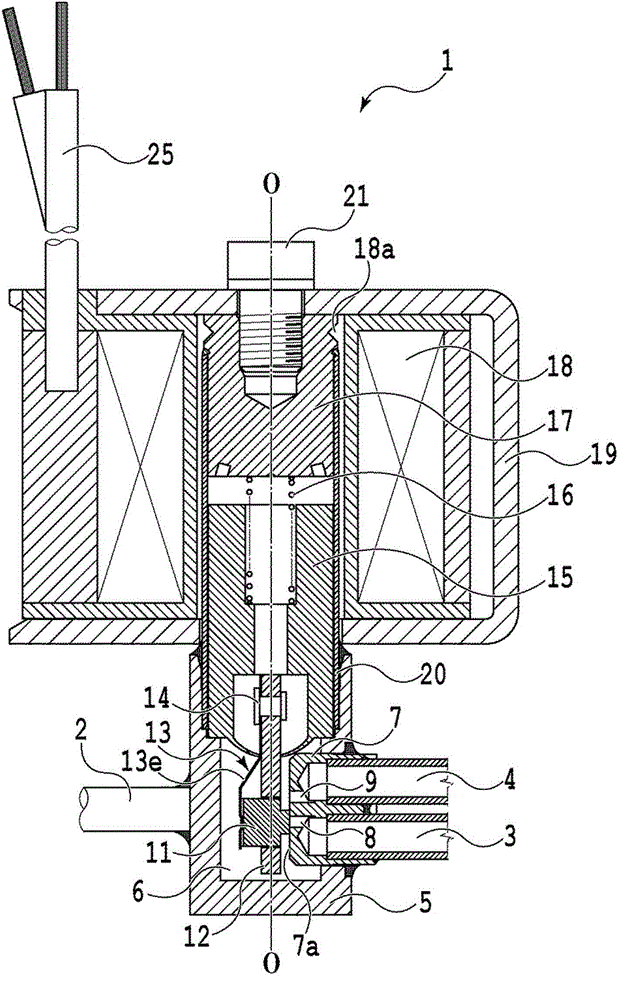

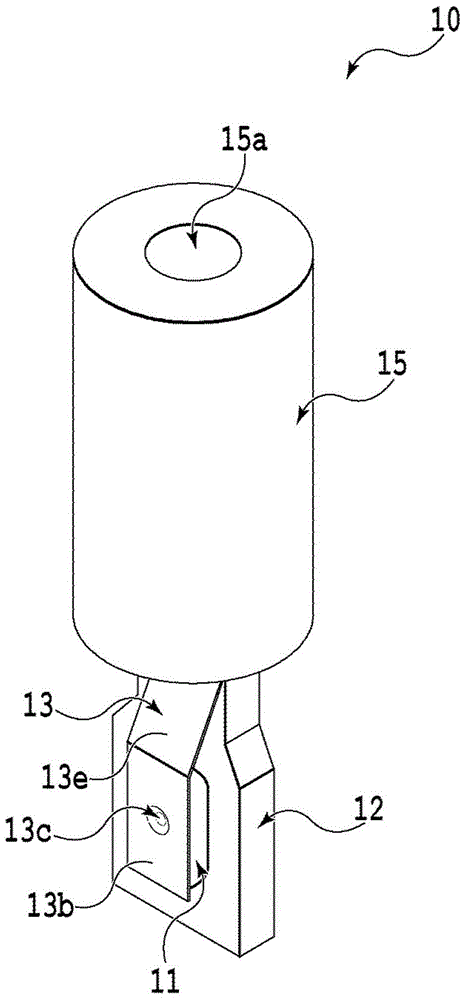

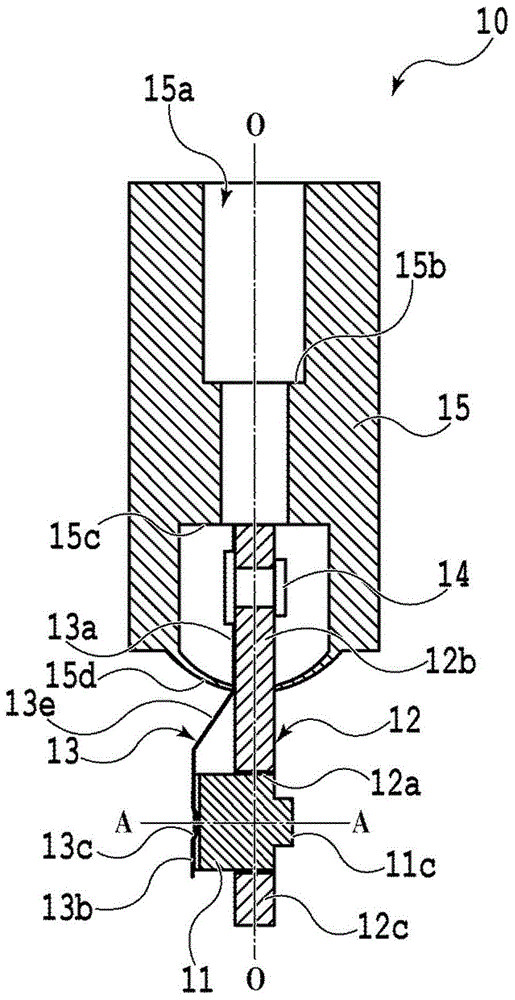

[0030] figure 1 A cross-sectional view of a typical embodiment of the slide valve of the present invention is shown. As an embodiment of the present invention, figure 1 The shown slide valve is an example of a three-way valve used in an automatic vending machine, but the present invention is not limited thereto, and can also be applied to a slide valve as a four-way valve incorporated in an air conditioner, a refrigerator, etc. as described later. .

[0031] The slide valve 1 of this embodiment has figure 1 The center axis O-O extending vertically in the vertical direction roughly includes a valve main body 5 , a valve element assembly 10 , and a solenoid 18 .

[0032]The valve main body 5 constituting the slide valve 1 defines a valve chamber 6, which is connected to the inlet side joint 2 communicating with the upstream side channel through the inlet side port (not shown), and connected to the outlet side port 8 and 9 through the outlet side port. The outlet-side joints ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com