Heat exchange tail heat recovery microwave oxygen insulation dryer

A tail heat recovery and heat exchange technology, which is applied in the direction of progressive dryers, dryers, and drying solid materials, can solve the problems of difficult heat transfer and penetration, unsatisfactory lily, and difficult industrial production, etc., to achieve uniformity Quality, tail heat recovery is simple and reliable, and the effect of improving drying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

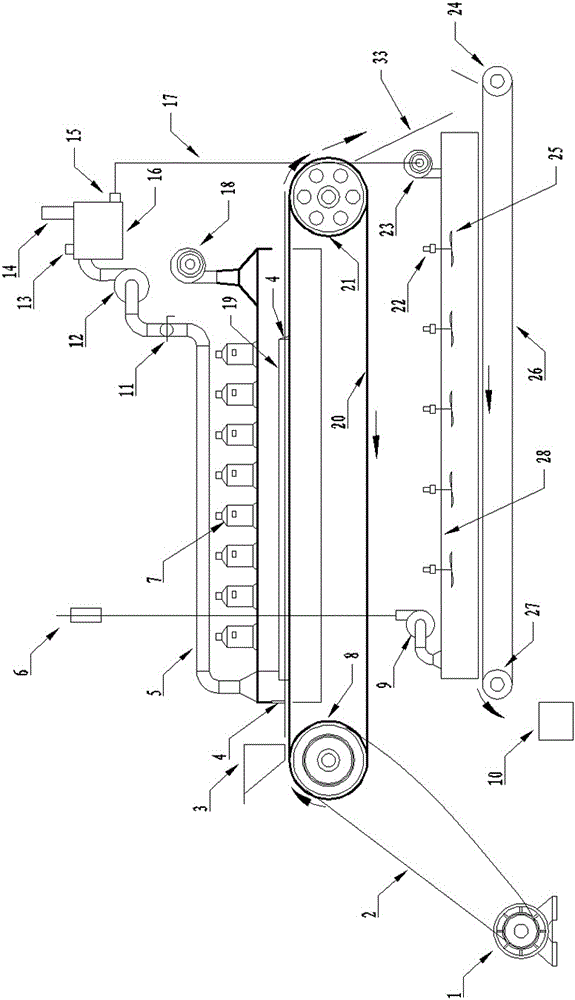

[0027] Now in conjunction with accompanying drawing, the present invention is described in further detail.

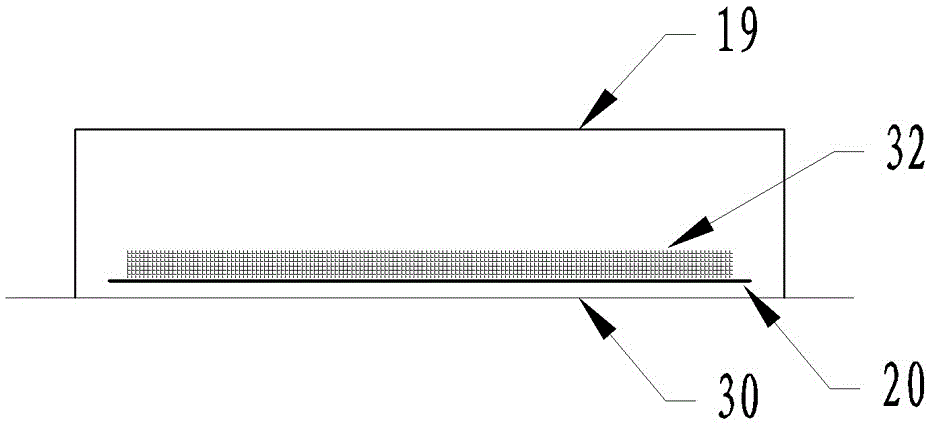

[0028] Such as figure 1 and figure 2 The shown heat exchange tail heat recovery microwave oxygen insulation dryer includes a conveyor belt 20, a microwave unit 7 and a glass cover 19. The glass cover 19 is tunnel-shaped and fixed on the substrate 30 below the conveyor belt 20. The tunnel-shaped glass cover 19 A microwave unit 7 is arranged outside, and the material 32 on the conveyor belt 20 is heated by the microwave unit 7 in the tunnel-shaped glass cover 19 and arrives on the conveyor belt 26 of the isolation box 28 through the slide plate 33; There is a barrier curtain 4 and a blower 18, the inlet is provided with a barrier curtain 4 and an air extraction pipe 5, the air extraction pipe 5 is provided with a damper 11 and connected to an exhaust fan 12, and the exhaust fan 12 is connected to a plate heat exchanger 16, and a plate heat exchanger 16 An exhaust port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com