Low-resistance sawtooth-shaped fin

A sawtooth-shaped, low-resistance technology, applied in heat exchange equipment, lighting and heating equipment, heat transfer modification, etc., can solve problems such as increased resistance, channel blockage, and high resistance, and achieve lower resistance and less blockage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

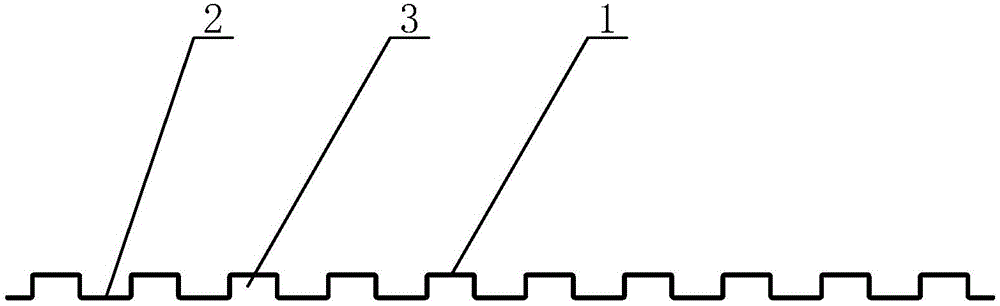

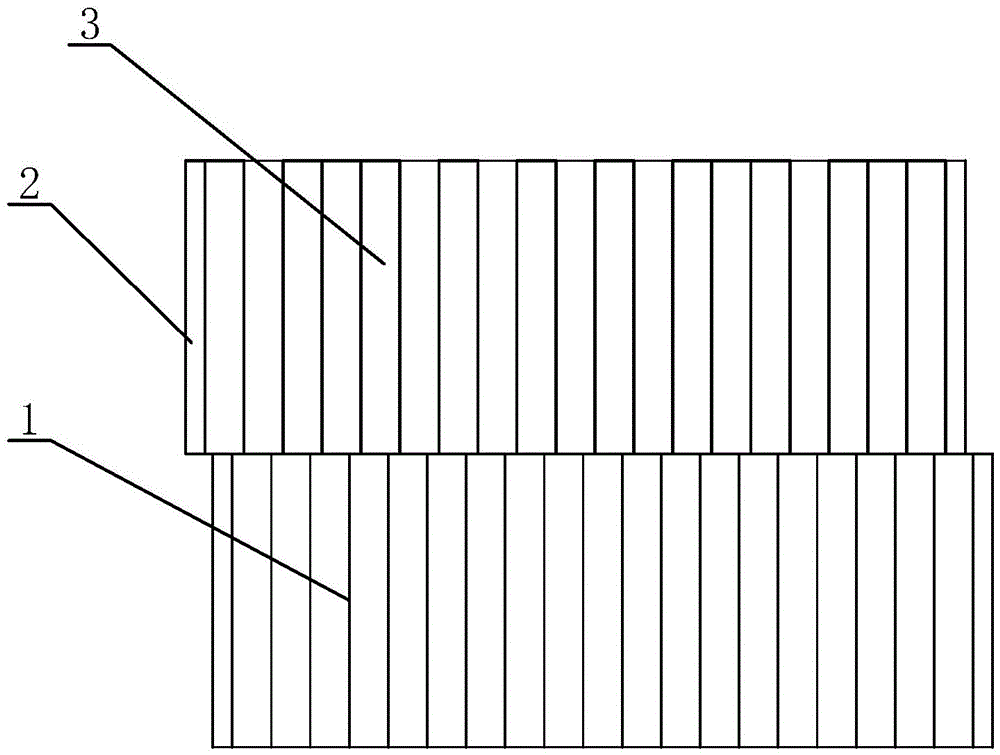

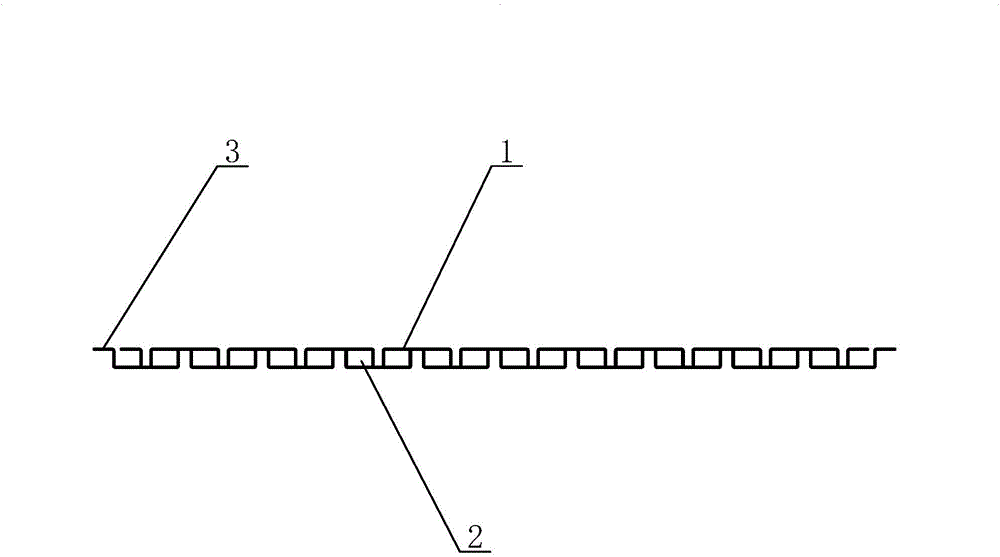

[0017] see Figure 1 to Figure 3 , the low-resistance zigzag fins are welded by several fin bodies 1 with a thickness of 0.15 mm, and several fin bodies 1 are arranged alternately in pairs. Starting from the convex mouth 3 of the fin plate 2, the shape of the convex mouth 3 is a U-shaped convex mouth 3, and 10 U-shaped convex mouths 3 are arranged on the described fin body. The pitch of the opening is 4mm, the depth of the protrusion 3 is 2mm, and the length of the fin body 1 is 30mm.

[0018] The pitch of the convex mouth 3 is reduced, which reduces the resistance of the fin body 1, and the fin body 1 with a large pitch and a small thickness has light weight and is convenient for transportation. In addition, the U-shaped convex mouth 3 can also be modified. With the V-shaped convex notch 3, the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com