Fuze High Overload Linear Inertial Force Simulation Support Clamping Device

An inertial force and high overload technology, applied in fuzes, weapon accessories, offensive equipment, etc., can solve the problems of inability to simulate the overload process, short action time, and inability to effectively release the recoil insurance, etc., to achieve simple structure, strong versatility, and rotation stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

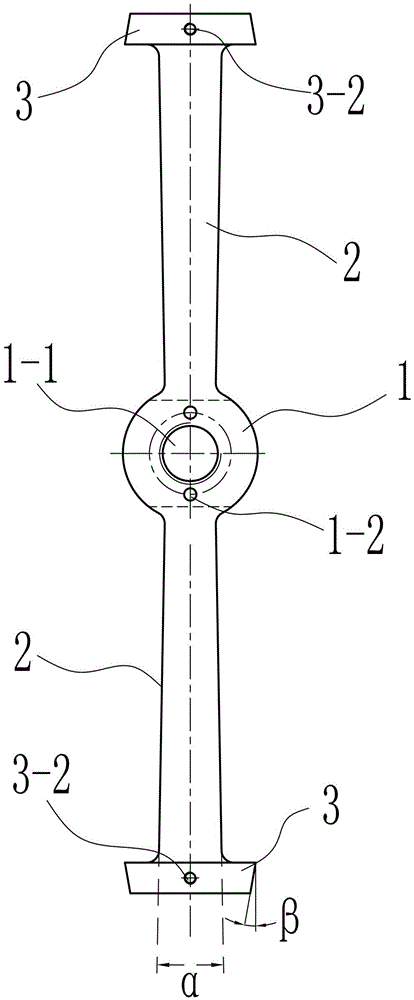

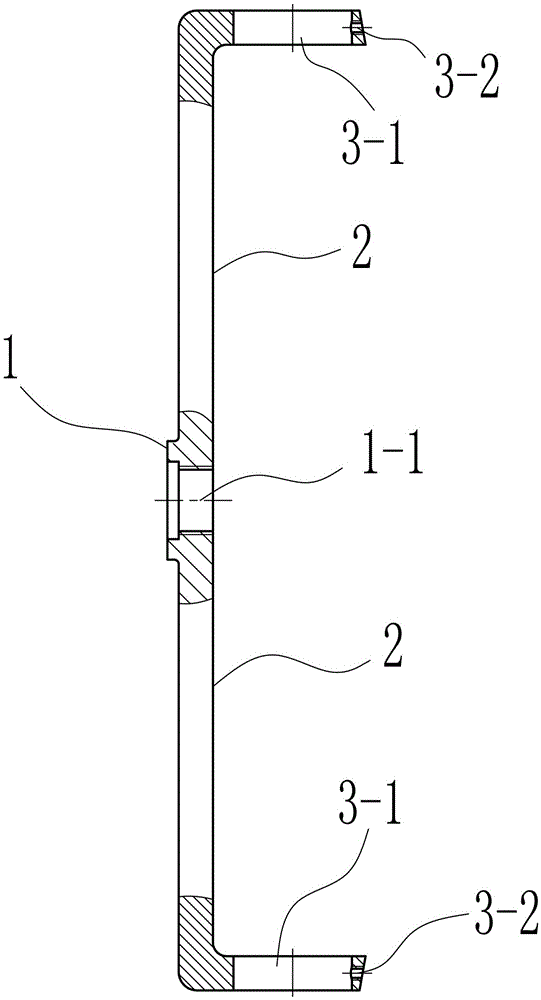

[0021] Attached below Figure 1-4 The present invention is further described in detail with specific embodiments.

[0022] as attached figure 1 The shown is a fuze high overload linear inertial force simulation support clamping device, which includes a rotating shaft fixing part 1 and a fuze long arm clamping mechanism mirrored at both ends of the rotating shaft fixing part 1, and the rotating shaft fixing part 1 is set at the center There is a connecting hole 1-1 for fixed connection with the rotating shaft 5, the connecting hole 1-1 is provided with an internal thread, and two pins for fixed connection with the rotating shaft 5 are symmetrically arranged on the rotating shaft fixing part 1 Holes 1-2. The clamping mechanism of the long arm of the fuze is symmetrical about its own axis to ensure stable operation during rotation.

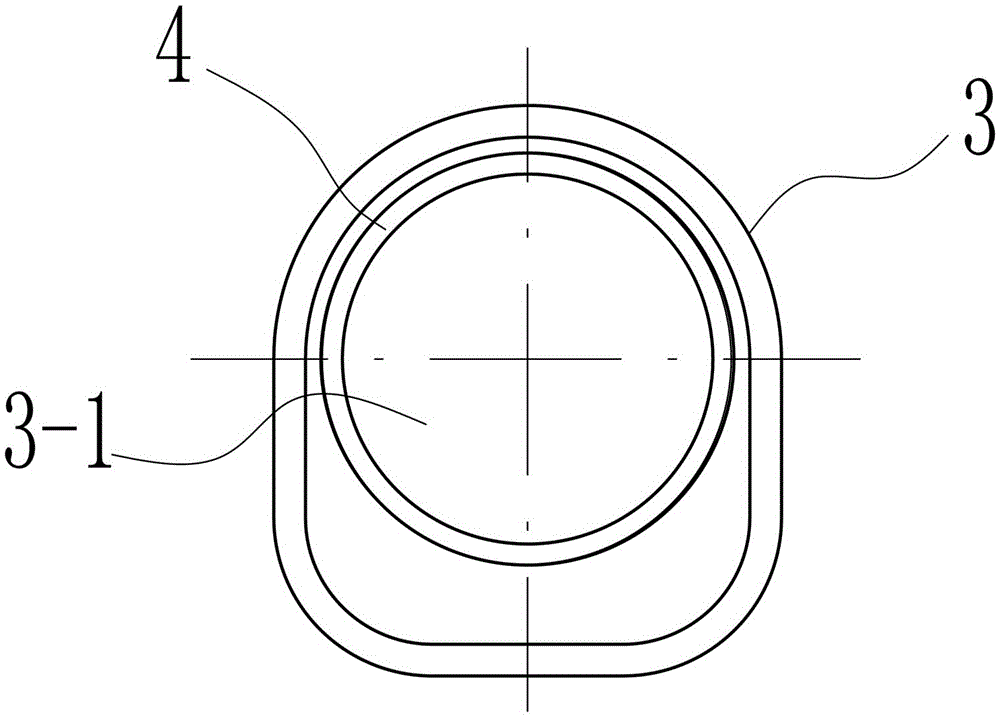

[0023] Such as figure 1 , 2 The long arm clamping mechanism of the fuze includes a connecting arm 2 fixedly connected to the rotating shaft fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com