A spray drift performance test device

A test device and performance technology, applied in the direction of measuring device, fluid dynamics test, mechanical parts test, etc., can solve problems such as difficulties and uncontrollable factors affecting droplet drift, and achieve a wide and universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

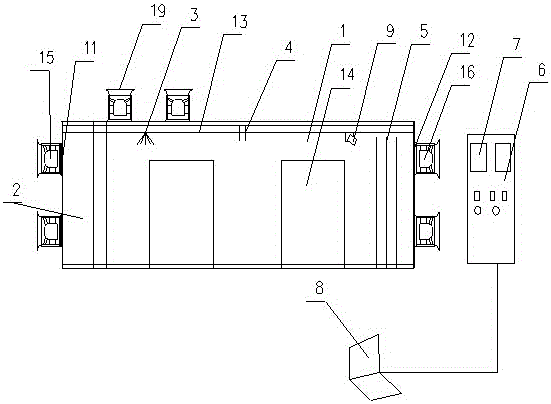

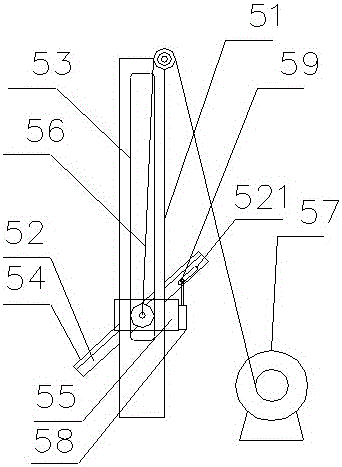

[0015] As shown in the figure, the spray drift performance test device includes a simulation chamber 1, a gas rectifier 2, an atomizing nozzle 3, a measurement module 4, a drift collection unit 5 and a control cabinet 6, and the two ends of the simulation chamber are respectively provided with Air inlet 11 and air outlet 12, the upper side of described simulation room is provided with longitudinal air supply port, and described air inlet, air outlet are respectively provided with air inlet mechanism 15, air outlet mechanism 16, longitudinal air supply mechanism 19, and described gas The rectifier 2 is set on the side of the simulation room close to the air inlet. When the air inlet mechanism and the air outlet mechanism are working, a uniform wind field is formed in the simulation room; when the longitudinal air supply mechanism is turned on, it produces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com