Lattice structure tester probe bay protection structure

A lattice structure and protection structure technology, applied in the field of lattice structure testing machine probe socket protection structure, can solve the problems of adsorption of debris, easy residue, damage, etc., to maintain the shape and service life, prevent The effect of chemical corrosion and cable damage prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

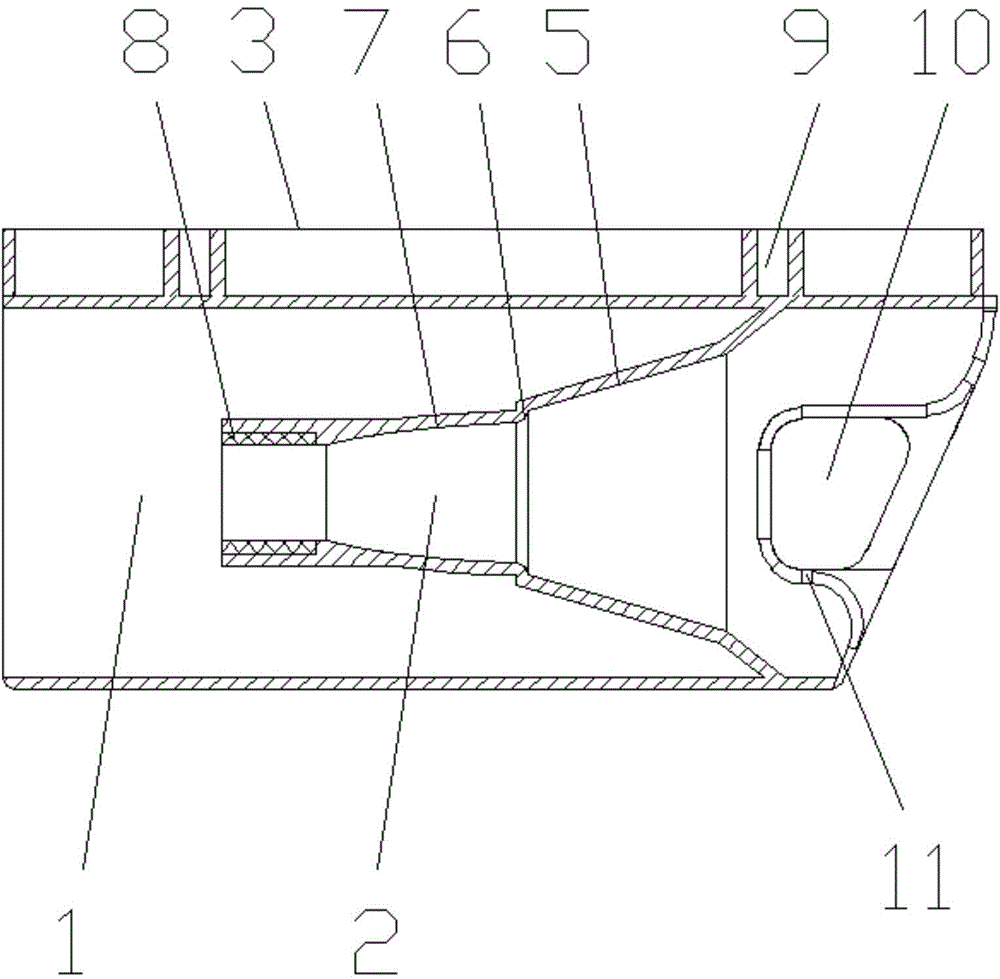

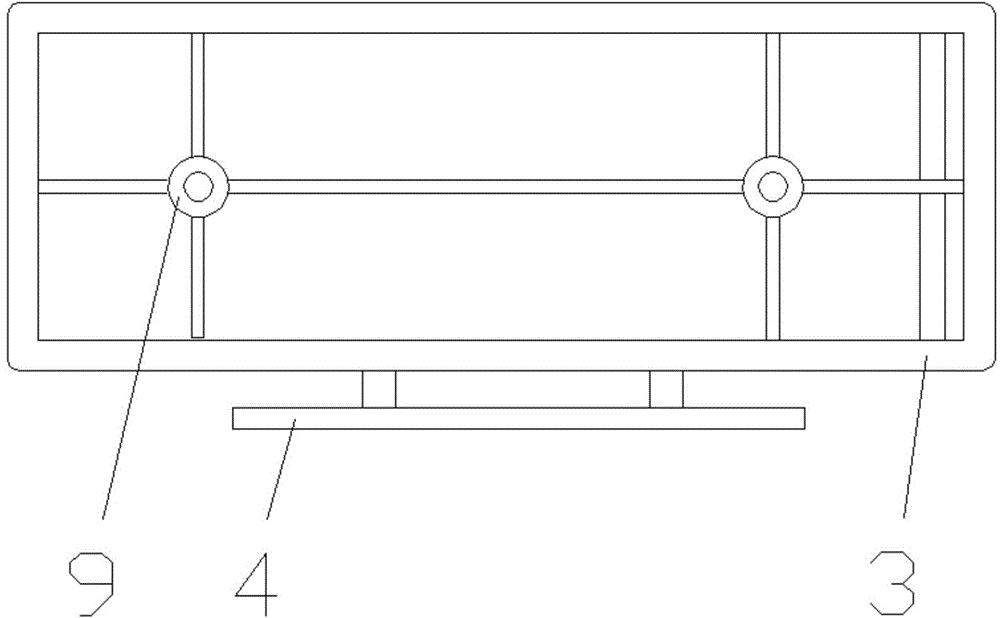

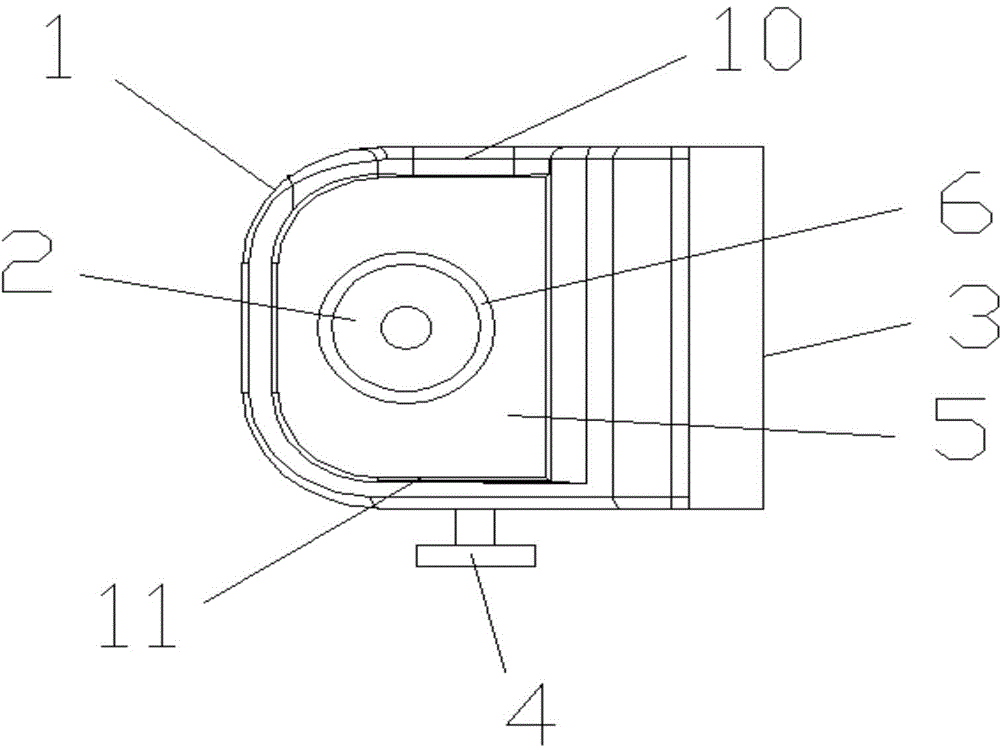

[0022] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

[0023] refer to Figure 1-Figure 6 As shown, the lattice structure testing machine probe socket protection structure includes a socket body 1, and the socket body 1 includes a socket insertion slot 2, a body installation part 3 and a cable hanging part 4. The rack insertion slot 2 is located in the middle of the rack body 1, and the rack insertion slot 2 includes the upper rack guiding vertebral groove 5, the middle probe head avoidance slot 7 and the lower metal collar 8 connected in sequence, The test probe 12 of the lattice structure testing machine is inserted into the insertion slot 2 of the socket, and the cables or lead wires of the test probe can be wound or hung on the cable hanging part 4 .

[0024] Further, the body installation part 3 is provided with a connecting screw hole post 9 and a reinforcing rib group.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com