Method for high-speed rotation laser direct-writing arbitrary graph

A technology of laser direct writing and high-speed rotation, applied in the field of high-speed rotating laser direct writing of arbitrary graphics and laser direct writing, it can solve the problems of difficult to guarantee accuracy, inability to write graphics, and inability to write, and achieve the effect of wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the examples, but the protection scope of the present invention should not be limited thereby.

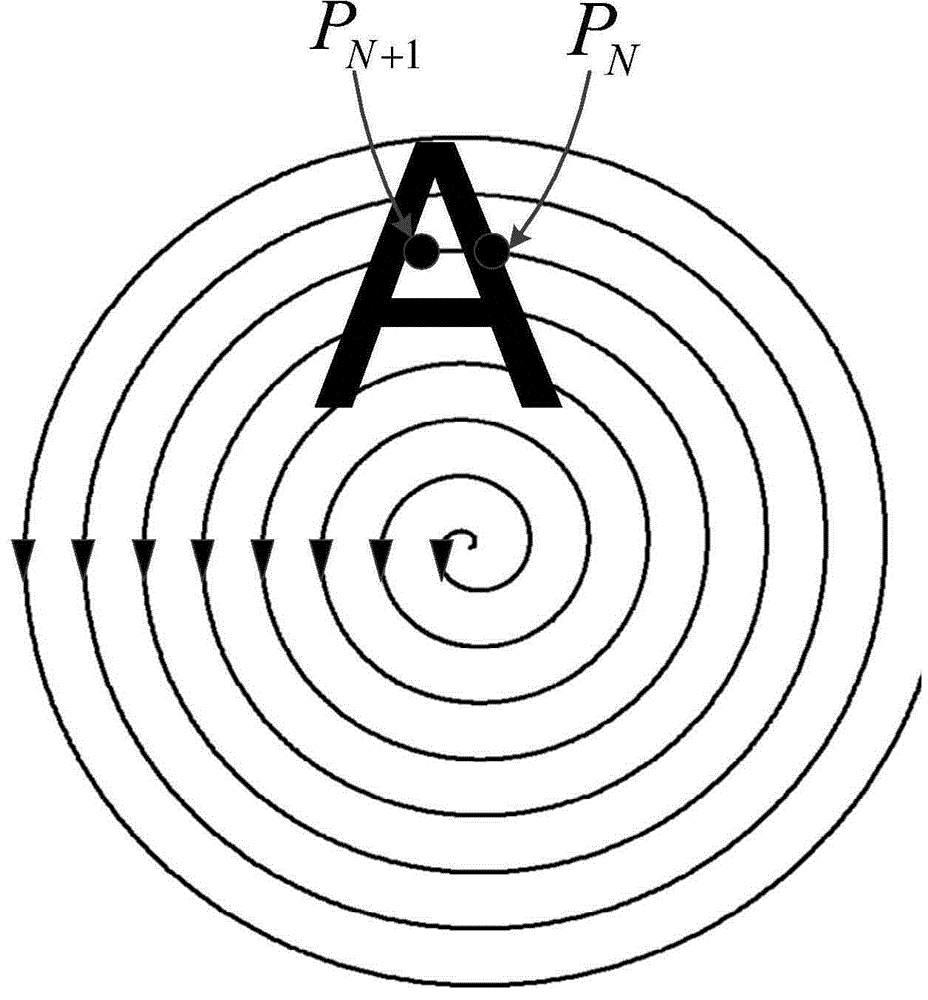

[0022] The method for directly writing arbitrary graphics with high-speed rotating laser of the present invention comprises the following steps:

[0023] 1) Build a polar coordinate laser direct writing system:

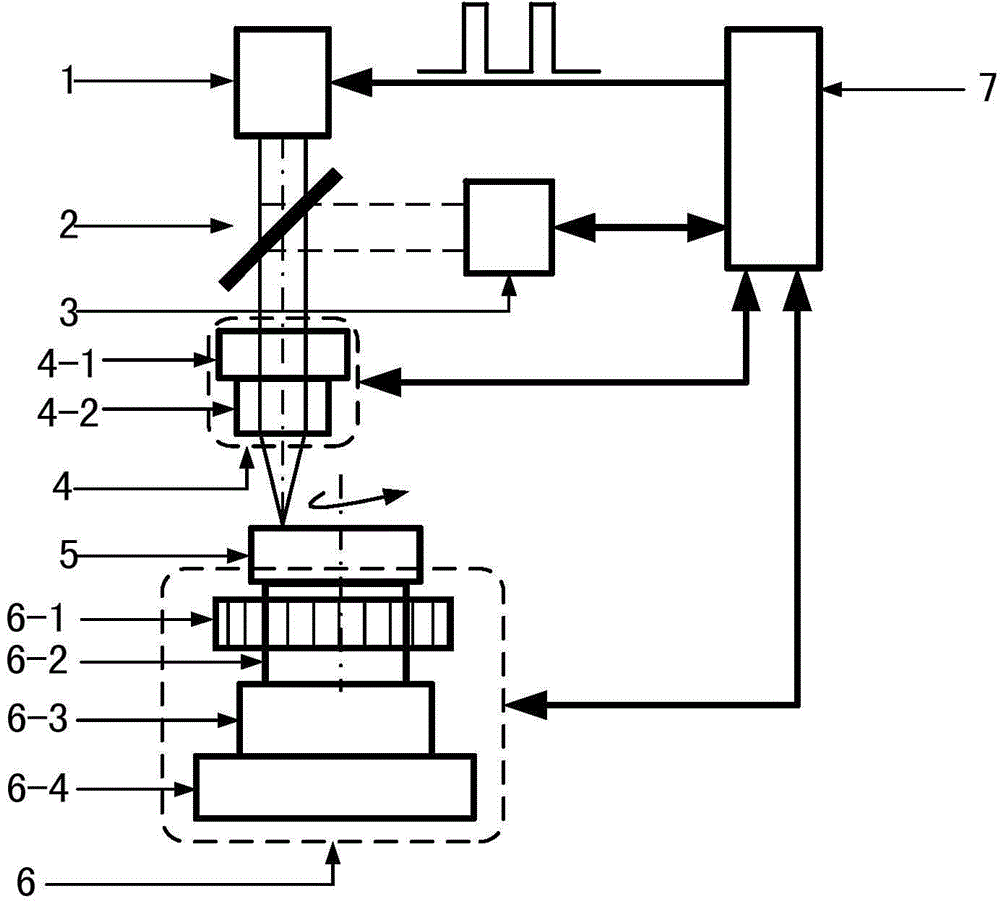

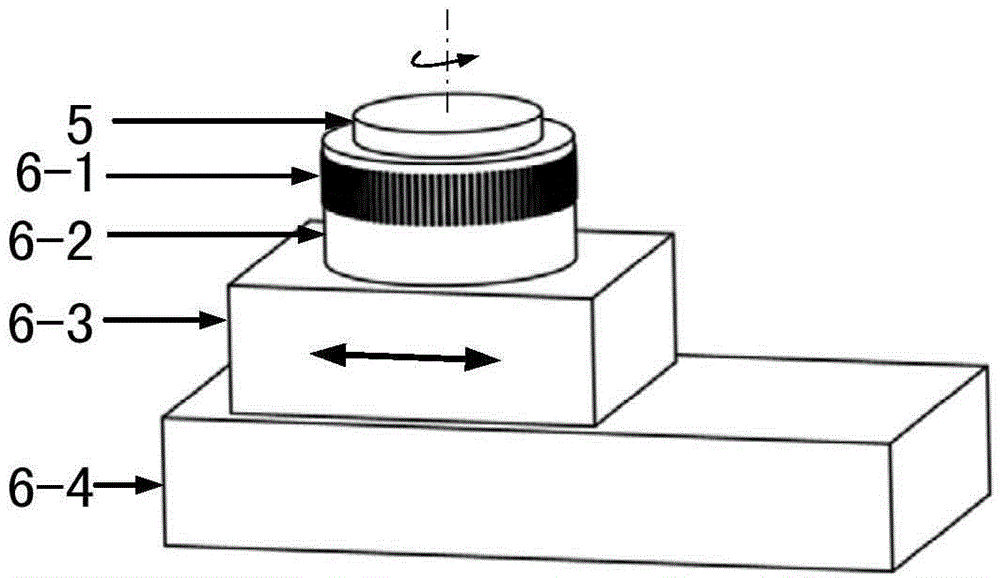

[0024] The system includes a modulatable laser light source module 1, a spectroscopic beam splitter 2, a defocus detection module 3, an adjustable focus converging objective lens module 4, a sample to be written 5, a rotary translation stage 6 and a general controller 7. The modulatable laser The light source module 1 and the out-of-focus detection module 3 are respectively located on both sides of the spectral beam splitter 2, and the angle between the optical axis of the light beam emitted by the modulated laser light source module 1 and the out-of-focus detection module 3 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com