Method for building liquid seal of ORVR (onboard refueling vapor recovery) oil filling pipe

A technology of liquid sealing and refueling tubes, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of inability to obtain test results, large manpower and material resources, and increased test costs, so as to facilitate popularization and application and reduce test costs. Cost, the effect of improving the sealing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

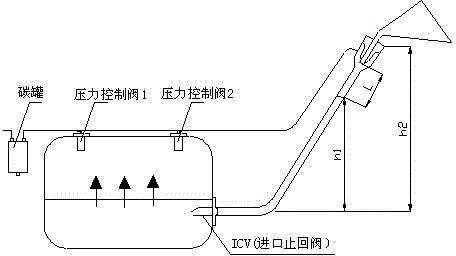

[0039] see figure 1 , a kind of method that establishes ORVR refueling pipe liquid seal, described method comprises the following steps:

[0040] 1) Measure the vertical distance from the fuel inlet of the fuel tank to the head of the filling pipe, h2=515mm;

[0041] 2) Select ICV, the inlet check valve, and measure its pressure drop. The pressure drop when the fuel flow Q is 38L / min is △P1=300Pa;

[0042] 3) Select the pressure control valve and measure its pressure drop. The pressure drop when the fuel vapor flow rate is 50L / min is △P2=90Pa;

[0043] 4) Select the carbon canister and measure its pressure drop. The pressure drop when the fuel vapor flow rate is 50 L / min is △P3=890Pa;

[0044] 5) The pressure generated by the liquid seal section in the oil filling pipe is P4, P4= ;

[0045] 6) The pressure generated by the fuel beam during refueling is P5, P5= ;

[0046] 7) The resistance generated between the fuel beam and the inner wall of the fuel pipe when refuelin...

Embodiment 2

[0068] see figure 1 , a kind of method that establishes ORVR refueling pipe liquid seal, described method comprises the following steps:

[0069] 1) Measure the vertical distance from the fuel inlet of the fuel tank to the head of the filling pipe, h2=515mm;

[0070] 2) Select ICV, the inlet check valve, and measure its pressure drop. The pressure drop when the fuel flow Q is 45L / min is △P1=340Pa;

[0071] 3) Select the pressure control valve and measure its pressure drop. The pressure drop when the fuel vapor flow rate is 55L / min is △P2=120Pa;

[0072] 4) Select the carbon canister and measure its pressure drop. The pressure drop when the fuel vapor flow rate is 55 L / min is △P3=940Pa;

[0073] 5) The pressure generated by the liquid seal section in the oil filling pipe is P4, P4= ;

[0074] 6) The pressure generated by the fuel beam during refueling is P5, P5= ;

[0075] 7) When refueling, the resistance generated between the fuel beam and the inner wall of the refuel...

Embodiment 3

[0097] see figure 1 , a kind of method that establishes ORVR refueling pipe liquid seal, described method comprises the following steps:

[0098] 1) Measure the vertical distance from the fuel inlet of the fuel tank to the head of the filling pipe, h2=515mm;

[0099] 2) Select ICV, the inlet check valve, and measure its pressure drop. The pressure drop when the fuel flow Q is 15L / min is △P1=140Pa;

[0100] 3) Select the pressure control valve and measure its pressure drop. The pressure drop when the fuel vapor flow rate is 19L / min is △P2=70Pa;

[0101] 4) Select the carbon canister and measure its pressure drop. The pressure drop when the fuel vapor flow rate is 19 L / min is △P3=370Pa;

[0102] 5) The pressure generated by the liquid seal section in the oil filling pipe is P4, P4= ;

[0103] 6) The pressure generated by the fuel beam during refueling is P5, P5= ;

[0104] 7) When refueling, the resistance generated between the fuel beam and the inner wall of the refueli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com