Numerical control machining center tool changing and machining process demonstration teaching aid

A machining process and machining center technology, which is applied in the field of CNC machining center tool change and machining process demonstration teaching aids, can solve the problems that teaching is not intuitive and difficult for students to understand, and achieves the effect of facilitating upgrade and replacement and solving hysteresis problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

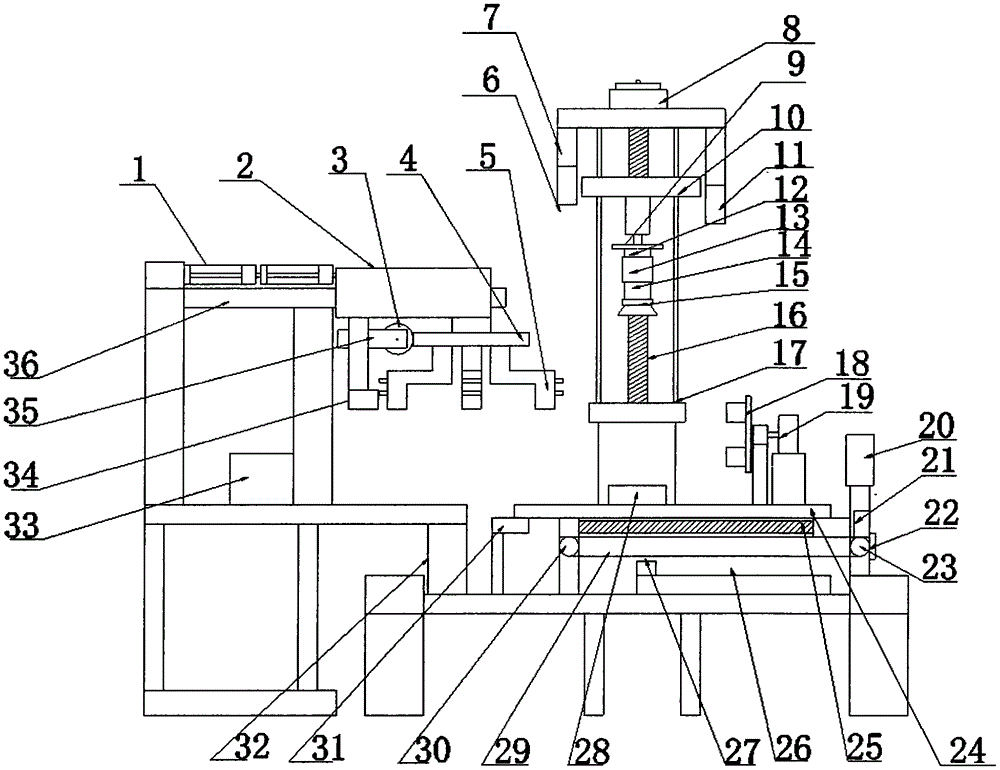

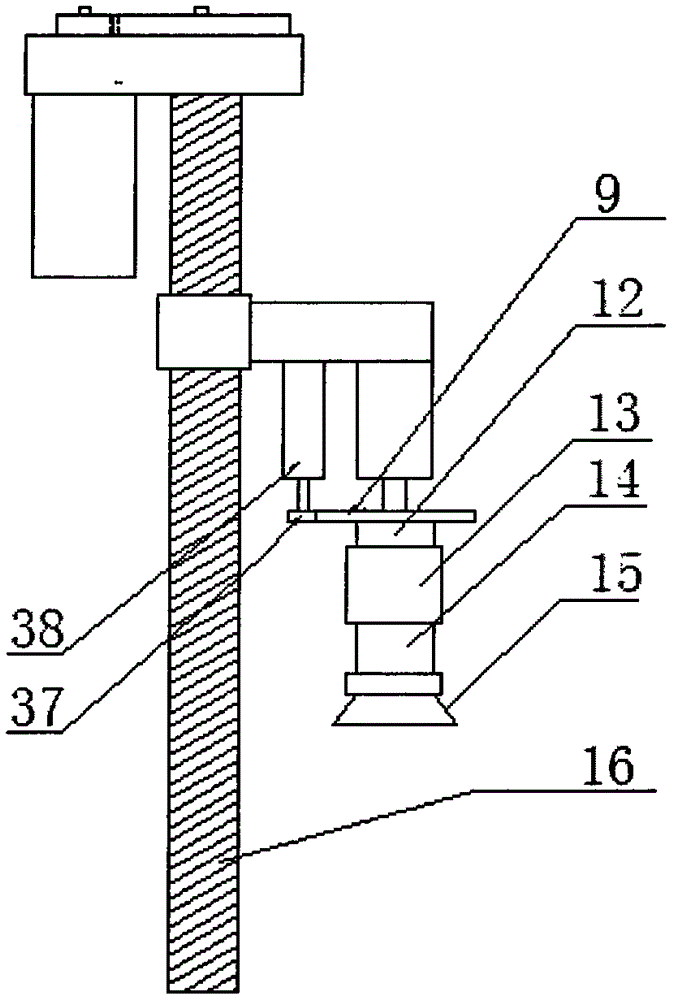

[0016] 1. Return to the origin: Press the switch a on the console 26, the motor A8 drives the worm B16 to rotate, the main shaft moves upwards driven by the worm slider 10, and stops after touching the travel switch B7. The workbench 24, under the action of the worm slider driven by the motor C20 and the motor D22, is limited by the travel switch D21 and the travel switch E31, and reaches the origin position specified by the x and y axes, and the indicator light 27 on the console 26 lights up to realize Demonstration of the process of returning to the origin;

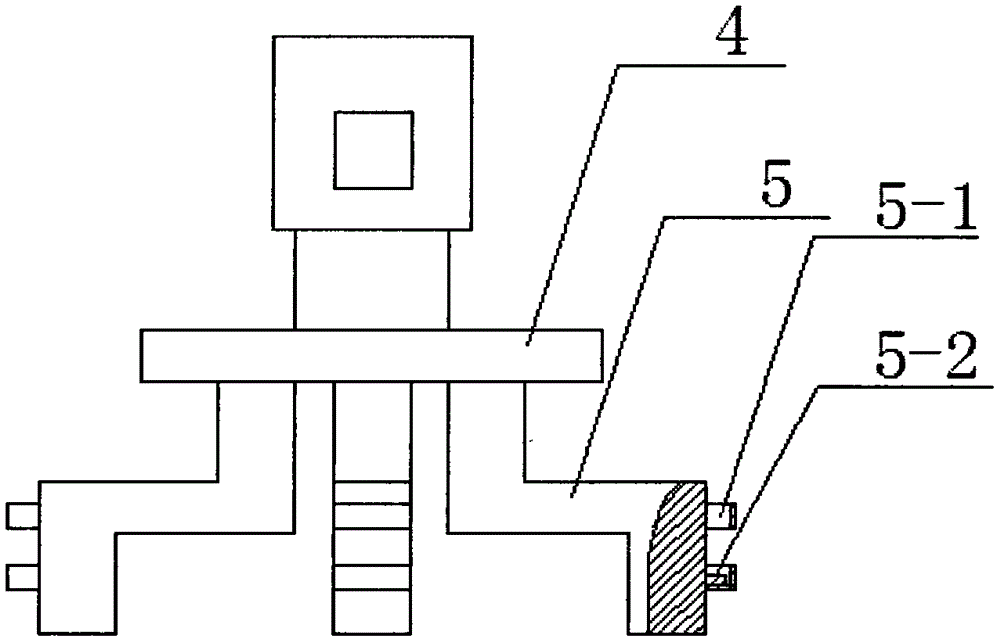

[0017] 2. Tool clamping: press the switch b on the console 26, the air pump 33 starts, the tool magazine reaches the bottom of the main shaft driven by the cylinder 1, the worm A3 rotates under the drive of the motor E35, and drives the disc-shaped gear 4 to rotate, and the The tool to be clamped moves directly below the main shaft, the motor A8 drives the worm B16 to rotate, the main shaft moves downwards driven by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com