Sliding contacts for high voltage appliances

A technology of sliding contacts and high-voltage electrical appliances, which is applied in the direction of contact engagement, etc., can solve the problems of easy deformation of contacts, no isolation, low carrying capacity, etc., and achieve reliable and stable motion structure, good dynamic and thermal stability, and improved stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

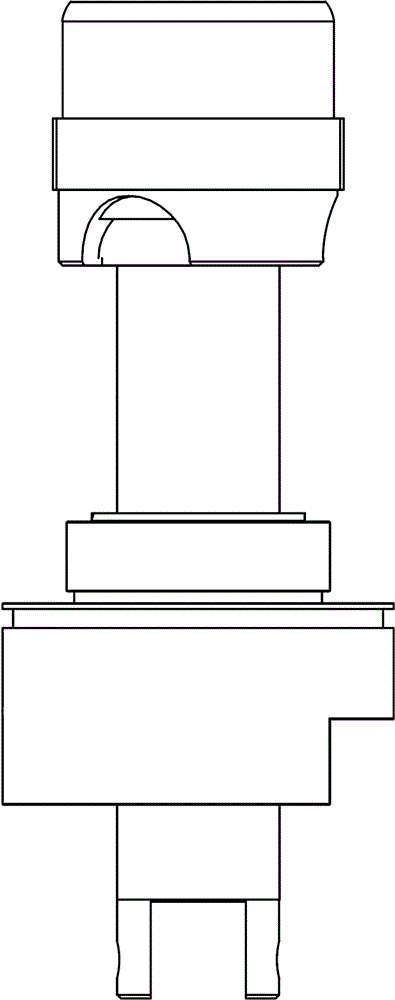

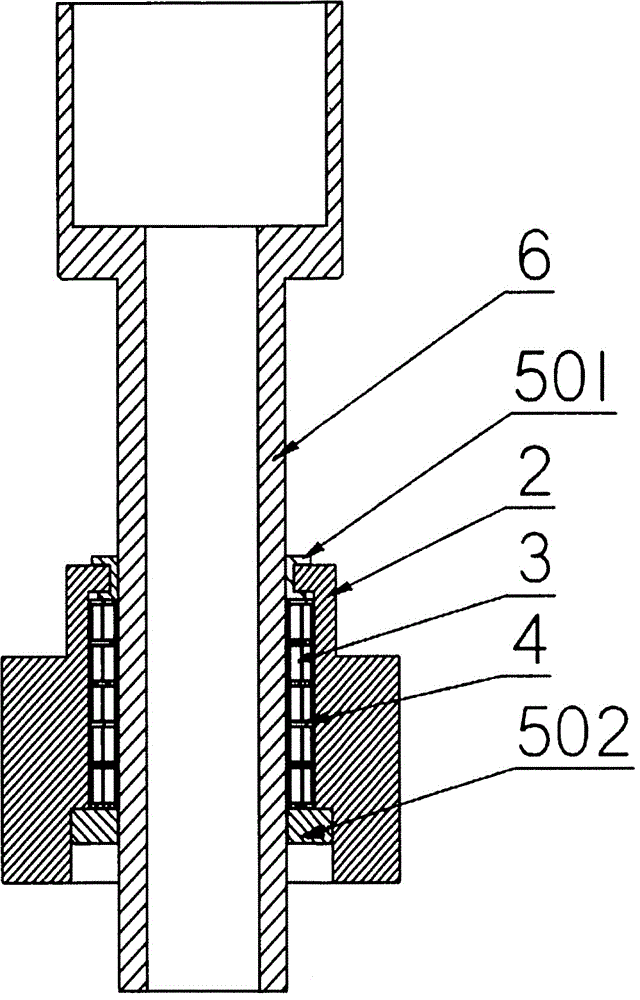

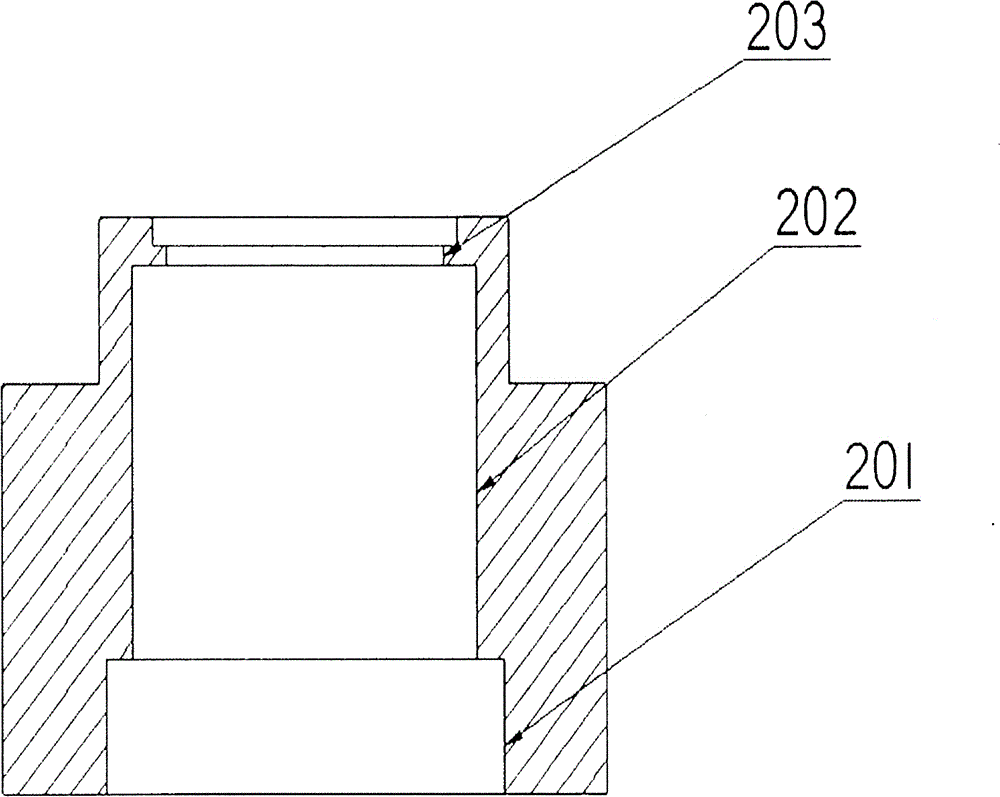

[0021] Such as Figure 1-7 As shown, the sliding contact used for high-voltage electrical appliances in this preferred embodiment includes contact finger placement block 2, sliding contact finger 3, contact finger separator 4, upper lubricating guide sleeve 501, lower lubricating guide sleeve 502, active drive The contact 6, wherein the contact finger placement block 2, the moving main contact 6 and the sliding contact finger 3 are in contact with each other.

[0022] The sliding contact is composed of a contact finger placement block 2, 5 sliding contact fingers 3, 6 contact finger partitions 4, an upper lubricating guide sleeve 501 and a lower lubricating guide sleeve 502, and all the sliding contact fingers 3 are rolled into a ring Insert into the hole 202 in the contact finger placement block, pad the contact finger separator 4 between two sliding contact fingers 3, and finally form a hollow sleeve, the outer diameter of the sliding contact finger 3 is in contact with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com