A kind of nickel hydroxide/carbon nanocomposite material doped with zinc and cobalt and its preparation method and application

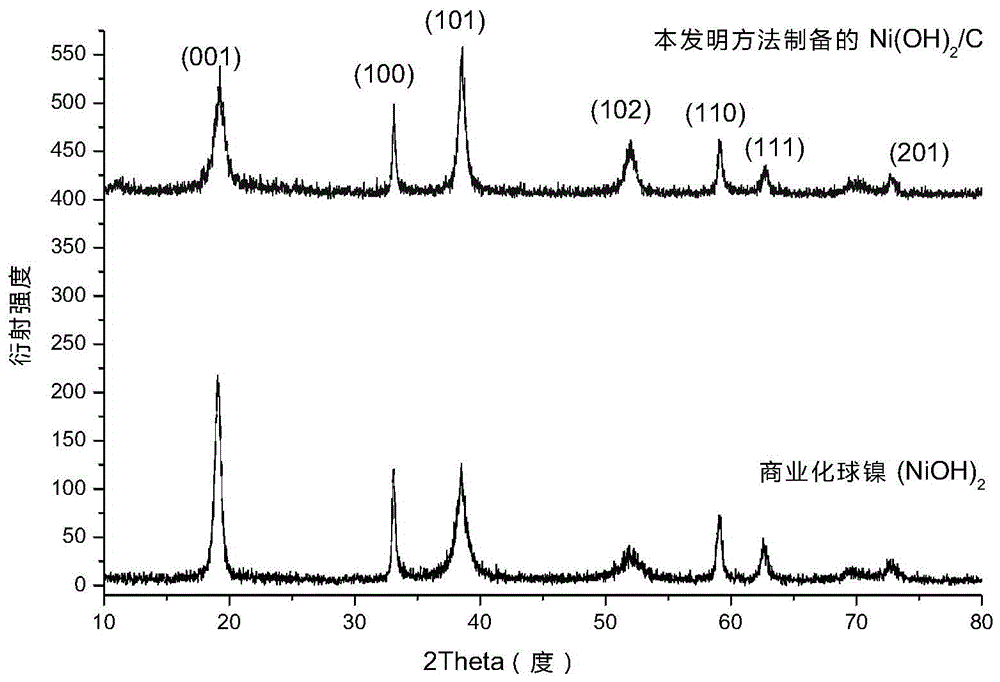

A technology of nickel hydroxide and composite materials, which is applied in the field of materials, can solve the problems of low actual utilization efficiency, uneven distribution of dopant element deposition, and restricted application, achieve excellent high-current charge and discharge characteristics, avoid uneven deposition reactions, Avoid the effect of co-deposition unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

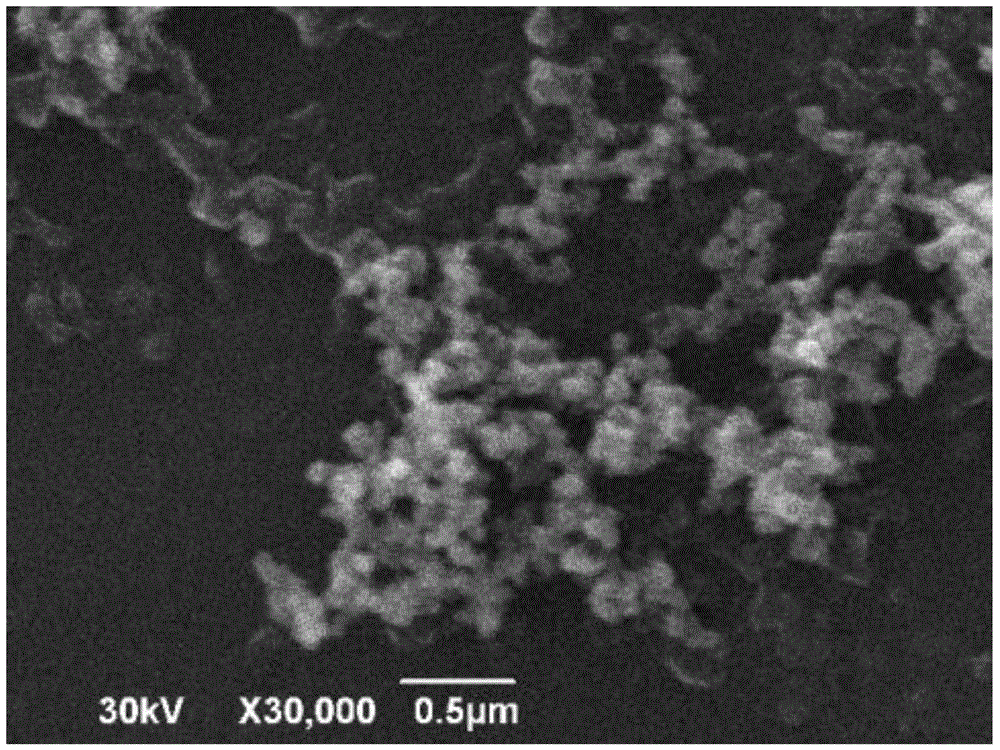

[0053] In this embodiment, acetylene black is selected as the base nano-carbon material, and the carbon mass ratio is 9.1wt.%, and the doped nickel hydroxide mass ratio is 90.9wt.%. Doped with 3% molar ratio of zinc and 1.5% molar ratio Cobalt in nickel hydroxide / carbon nanocomposites. The specific implementation process is:

[0054] 1. The mass ratio of acetylene black is 9.1wt.%, and the mass ratio of nickel hydroxide doped with zinc and cobalt is 90.9wt%. Take acetylene black and place it in an ultrasonic reactor, add an appropriate amount of ethanol as a wetting Dispersant (the amount of ethanol is the basic requirement to fully wet the carbon powder), ultrasonic treatment for 60 minutes.

[0055] 2. Nickel chloride (NiCl 2 ), cobalt chloride (CoCl 2 ) and zinc chloride (ZnCl 2 ) as raw material preparation (Ni 2+ +Zn 2+ +Co 2+ ) a mixed solution with a total concentration of 2.0mol / L as a reaction solution, wherein the molar ratio of nickel, zinc and cobalt is 95....

Embodiment 2

[0061] In this example, acetylene black is used as the carbon material to prepare nickel hydroxide doped with 3% molar ratio of zinc and 1.5 molar ratio of cobalt with a carbon mass ratio of 1wt.% and a doped nickel hydroxide mass ratio of 99wt.%. / carbon nanocomposites.

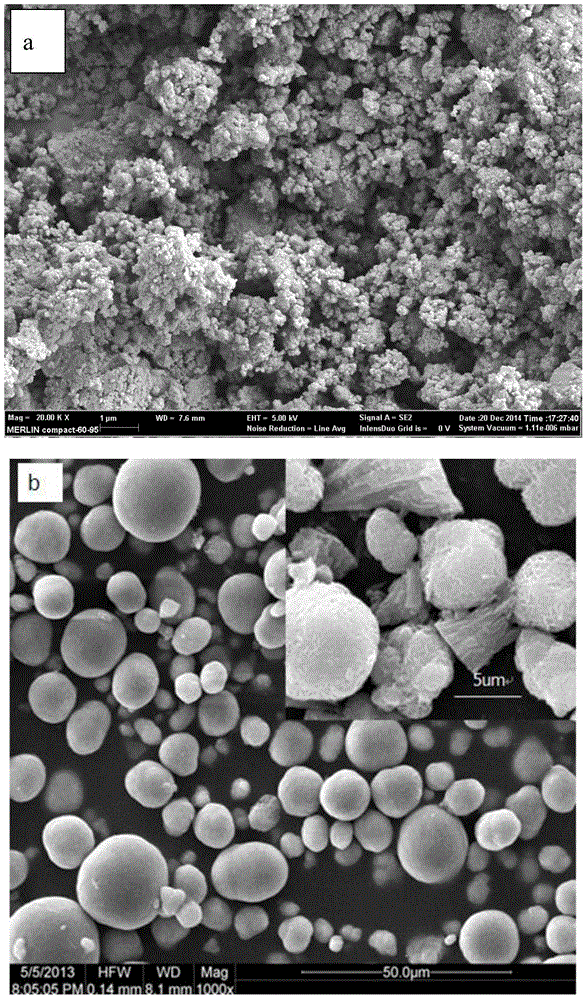

[0062] The types of raw materials used in this example and the preparation process of the composite material are the same as those in Example 1. The difference from Example 1 is that the ratio of carbon and (nickel+cobalt+zinc) salt reactants required in the preparation process is different, that is, the mass ratio of acetylene black in this example is 1wt.%, doped with hydrogen The mass proportion of nickel oxide is 99wt.%. The results of different rate discharge curves of the nickel hydroxide / carbon nanocomposite material doped with zinc and cobalt prepared in this example are as follows Image 6 shown. and Figure 5 Compared with the test results of the commercial spherical nickel hydroxide doped in ...

Embodiment 3

[0064] In this example, acetylene black was used as the carbon material to prepare a nickel hydroxide / carbon nanocomposite material doped with zinc and cobalt with a carbon mass ratio of 33.3 wt.% and a nickel hydroxide doped mass ratio of 66.7 wt.%.

[0065] The types of raw materials used in this example and the preparation process of the composite material are the same as those in Example 1. The difference from Example 1 is that the mass ratio of carbon and (nickel+cobalt+zinc) salt reactants required in the preparation process is different. In this example, the mass ratio of acetylene black is 33.3wt.%, doped with hydrogen The mass proportion of nickel oxide is 66.7wt.%. The results of different rate discharge curves of the nickel hydroxide / carbon nanocomposite material doped with zinc and cobalt prepared in this example are as follows Figure 7 shown. Compared with the performance of the doped commercial spherical nickel hydroxide positive electrode material, the bigges...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com