FFC (flexible flat cable) connector, direct-lit backlight module and wiring device

A technology for backlight modules and connectors, which is applied to the components, connections, coupling devices and other directions of connection devices, can solve problems such as low assembly efficiency, cumbersome connection processes, and complicated connection wire access methods, so as to improve assembly efficiency, Simple wiring method, fixed and reliable wiring method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

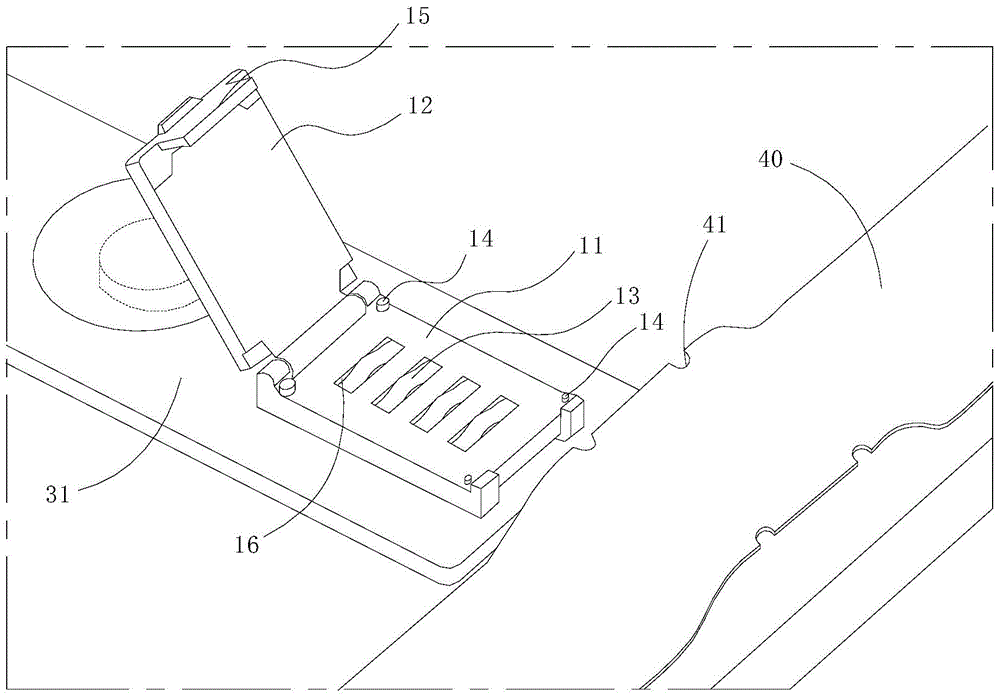

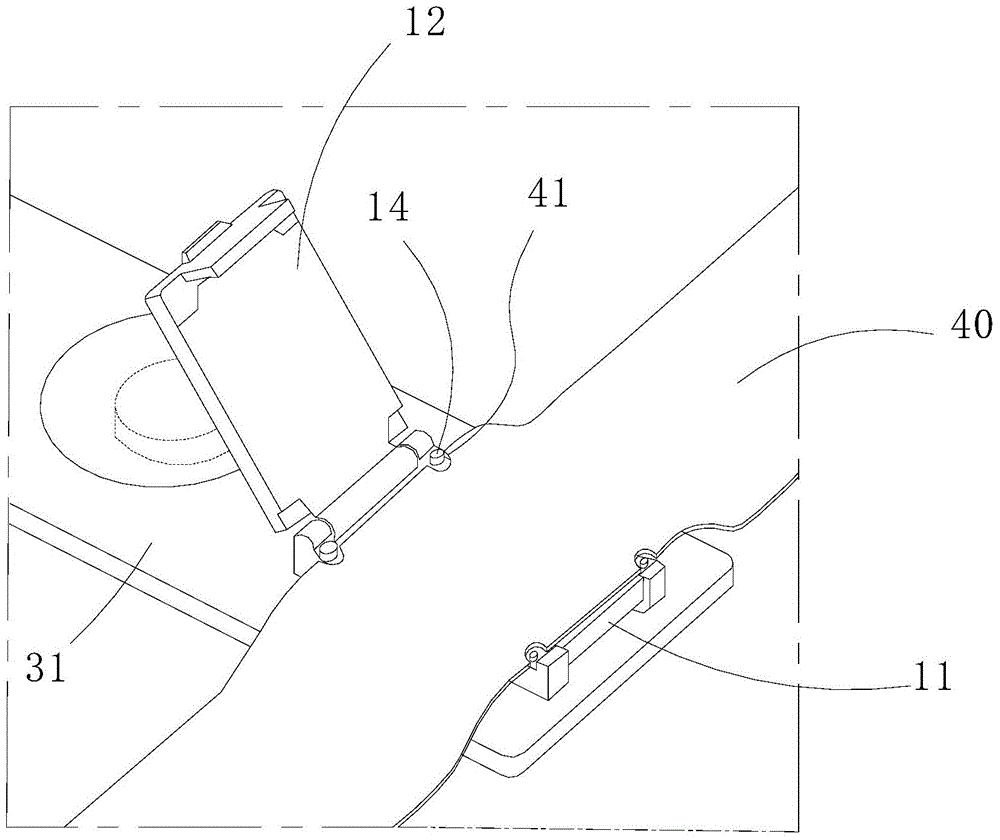

[0028] refer to figure 1 , the FFC (Flexible Flat Cable, flexible flat cable) connector of the present invention includes: a base 11, an upper cover 12, a shrapnel 13 and a positioning piece 14, wherein the base 11 is used to be fixed on the light bar assembly, and the upper cover 12 is rotatable Hinged on the base 11, the shrapnel 13 is mainly used to conduct the external power supply and the light bar assembly. The shrapnel 13 is set on the base 11 and the top of the shrapnel 13 protrudes from the upper surface of the base 11, and the bottom end of the shrapnel 13 protrudes from the base. 11 The lower surface is electrically connected to the light bar assembly. The top of the shrapnel 13 is higher than the upper surface of the base 11, and the surface of the FFC cable 40 opposite to the shrapnel 13 is provided with a conductive terminal in electrical contact with the shrapnel 13, which plays a conductive role and can also connect the FFC row placed on the base 11. The wire ...

Embodiment 2

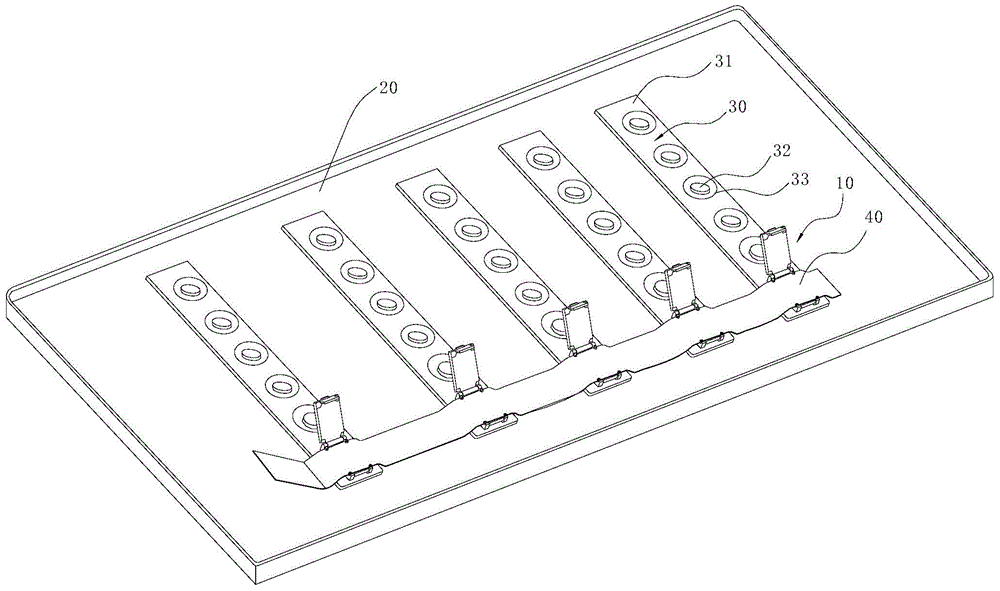

[0034] Such as figure 2 and image 3 As shown, the direct-lit backlight module of the embodiment of the present invention includes a rear case 20, a plurality of parallel and spaced light bar assemblies 30, FFC cables 40 and FFC connectors 10, and the light bar assemblies 30 are fixedly arranged on the rear case 20. Inside, each light bar assembly 30 is correspondingly provided with an FFC connector 10 . The FFC cable 40 is sandwiched between the base 11 and the upper cover 12 of the FFC connector 10, combined Figure 4 , the FFC cable 40 is provided with a conductive terminal 42 electrically connected to the elastic piece 13 , and the bottom end of the elastic piece 13 is electrically connected to the light bar assembly 30 .

[0035] The light bar assembly 30 includes a substrate 31 , an LED light bead 32 and a lens 33 . A notch 41 is formed in the width direction of the FFC cable 40 , and a positioning member 14 protrudes from the upper surface of the base 11 , and the p...

Embodiment 3

[0040] Such as Figure 4 and Figure 5 The FFC cable 40 includes a notch 41, a conductive terminal 42, a plug terminal 43, an adhesive part 44, and a release film 45. The plug terminal 43 is located at both ends of the FFC cable 40 in the length direction, and the conductive terminal 42 is located at multiple Between the plug terminals 43 , each of the conductive terminals 42 and the plug terminals 43 includes a plurality of contacts to ensure reliable contact with the light bar assembly 30 . After the release film 45 is peeled off, roll the winding wheel 100, and the elastic buffer shaft 102 elastically presses the rolling wheel 101 under the action of an external force, thereby pressing the FFC cable 40, and using the sticking part 44 to stick the FFC cable 40 on the rear case 20 and on the base 11 of the corresponding FFC connector 10 .

[0041] The wiring device of the embodiment of the present invention can be applied to the direct type backlight module of the second em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com