Harvesting machine for root-tuber crop in deep soil layer

A technology for rhizomes and harvesters, applied in excavating harvesters, harvesters, excavators, etc., can solve the problems of high labor intensity, cumbersome operation, low work efficiency, etc., so as to increase the depth of excavation operations and avoid the accumulation of floating soil. , the effect of reducing the cost of harvesting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

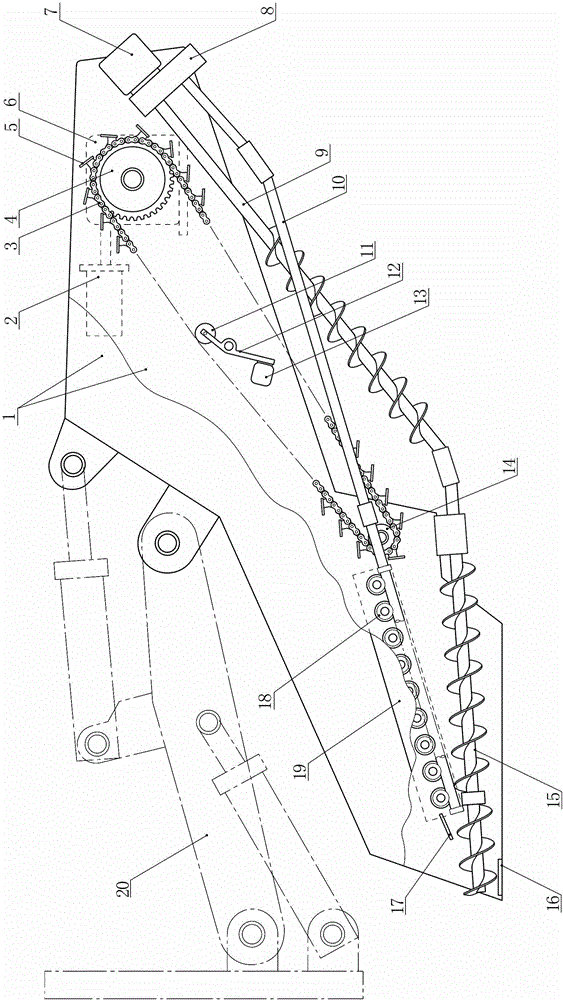

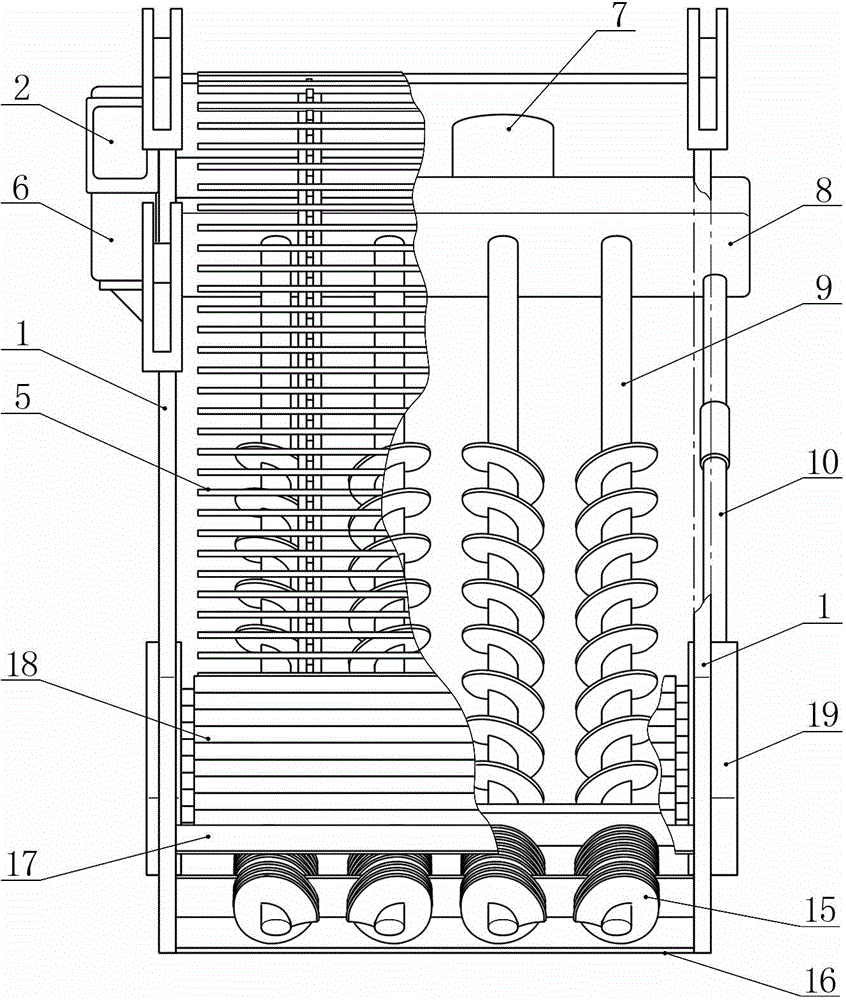

[0028] from Figure 1 to Figure 2 It can be seen that the technical solution of the present invention is: including a power device, a main gearbox 8 with multiple outputs, a reducer 6, and a boom 20; the power device includes a conveyor belt motor 2 and a main power motor 7 connected to the input end of the main gearbox;

[0029] The invention also includes a frame, an auger rod 15, a front conveyor, a conveyor drive shaft, a multi-output roller gearbox 19, a conveyor belt mechanism, and a soil-discharging auger 9; rear.

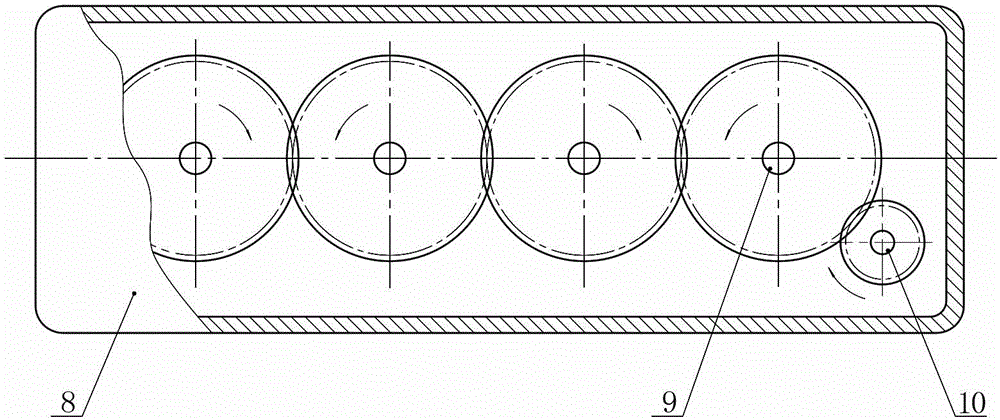

[0030] Side baffles 1 are fixed symmetrically on both sides of the frame, and the side baffles 1 are arranged in a wedge shape with a low front and a high rear, and a conveying narrow channel is formed between the baffles on both sides; The auger rod 15 of soil is provided with a helical blade on the rod body, and the auger rod 15 is arranged in pairs with a low front and a low height and a small angle at the back. The angle between the rod body and the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com