Reciprocating manipulator for machining punching machine

A reciprocating, manipulator technology, applied in the field of mechanical processing, can solve the problems of workers' safety cannot be guaranteed, low degree of automation, high labor intensity, etc., and achieve the effect of easy promotion and use, high degree of automation and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

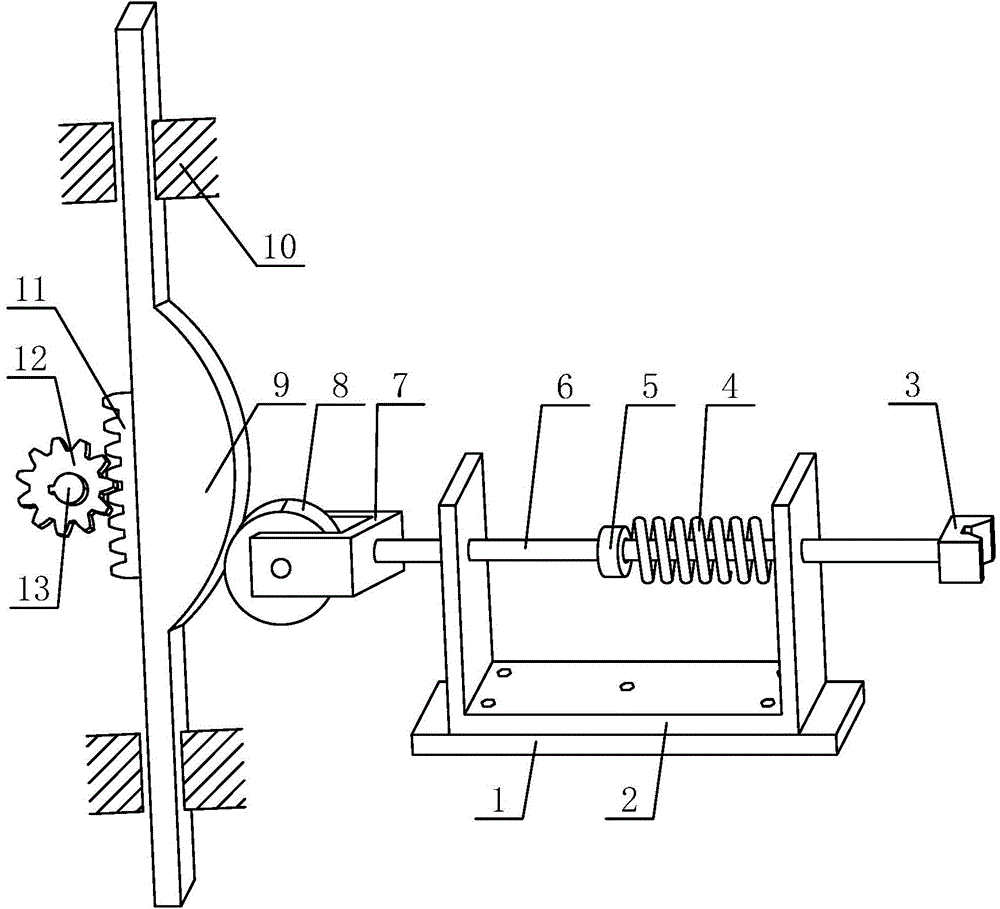

[0017] Such as figure 1 The shown reciprocating manipulator for punch processing includes a base 1, a U-shaped bracket 2 fixed and installed on the upper side of the base 1 by a plurality of bolts for supporting the push rod 6 to move left and right in the horizontal direction, slidingly arranged on the mounting The disc cam 9 used to drive the push rod 6 to slide forward on the frame 10, the return spring 4 used to drive the push rod 6 to reset, and the power shaft 13 used to provide power; the middle part of the push rod 6 is fixed A spring stopper 5 is provided, and the return spring 4 is arranged between the spring stopper 5 and the U-shaped bracket 2, and one end of the push rod 6 is welded or screwed and fixedly installed with a handle for removing the workpiece from the punching machine for processing. Elastic pusher 3, the other end of the push rod 6 is welded or fixed with a roller frame 7, and the roller frame 7 is rotated by a pin to install a roller that cooperates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com