'Pineapple-shaped' milling cutter applicable to high-speed machining for end surface, side surface and inclined surface in situ

A high-speed cutting and milling cutter technology, applied in milling cutters, metal processing equipment, manufacturing tools, etc., can solve problems that affect cutting efficiency or cutting accuracy, small diameter, limit cutting efficiency and cutting quality of machining centers, and reduce cutting The effect of increasing force, improving stability, improving cutting efficiency and cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

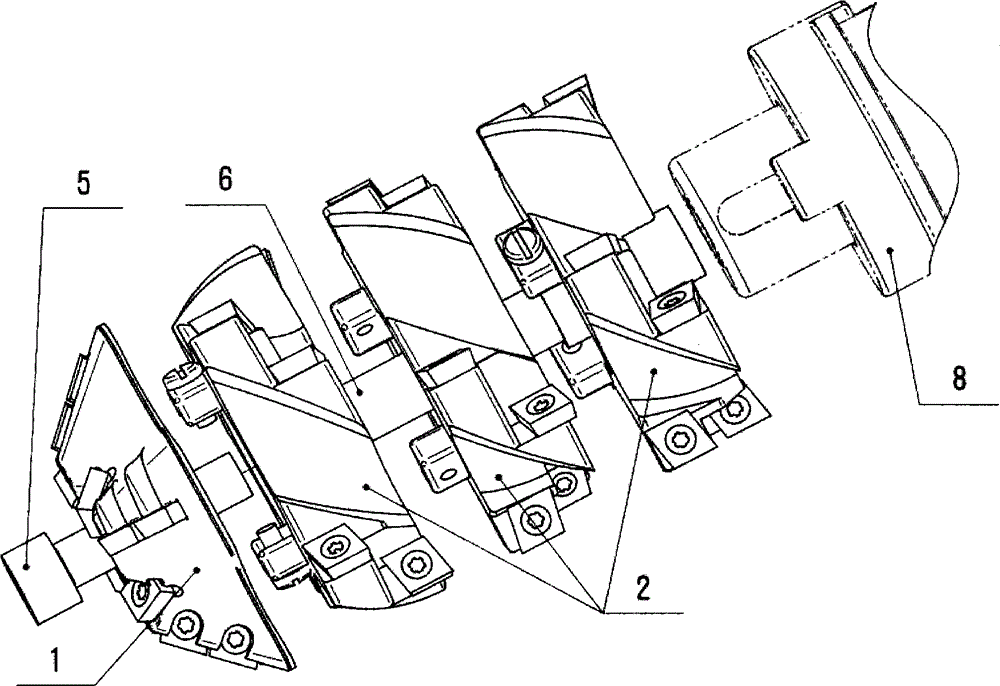

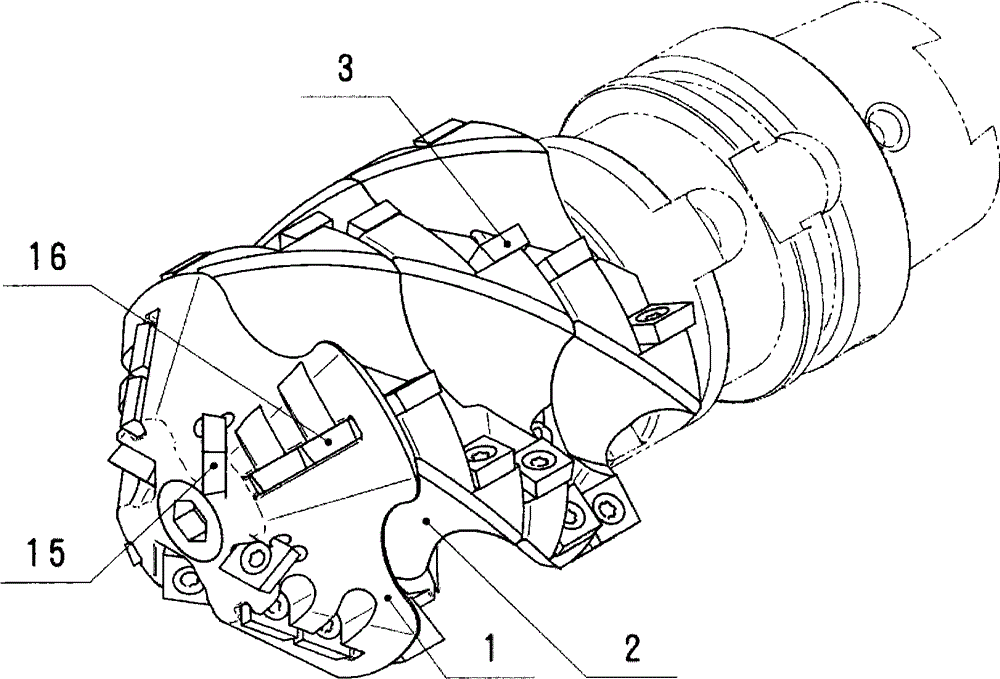

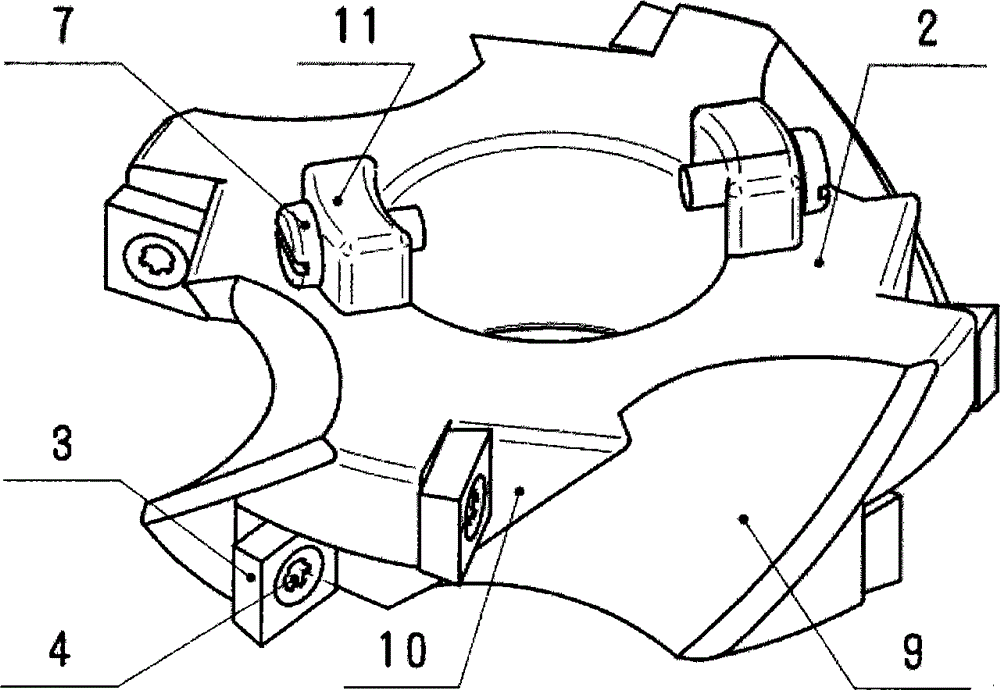

[0026] as attached figure 1 And attached figure 2 As shown, the present invention provides a "pineapple-shaped" milling cutter suitable for in-situ high-speed cutting on three sides of the end side. The milling cutter includes a milling cutter bottom support 1 and a cutter body. It is fixed with the connecting bolt 6, and installed on the peripheral machining center spindle through the tool handle 8 as a whole. The cutter body includes at least one milling cutter side cutter body 2. In this embodiment, the milling cutter side cutter body 2 adopts three coaxial arrangements and is recorded as the top layer, the middle layer and the bottom layer, and its number can be increased or decreased according to actual needs. The shape of the milling cutter is similar to that of a pineapple, that is, the arrangement of the cutters is like a "pineapple", and the cu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap