Laser cutting device

A technology of laser cutting and laser cutting head, applied in laser welding equipment, optics, nonlinear optics, etc., can solve the problems of liquid crystal panel cannot be found, liquid crystal panel inflow, and laser cutting device cannot detect the edge of liquid crystal panel, etc. The effect of simple structure, easy assembly, and easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

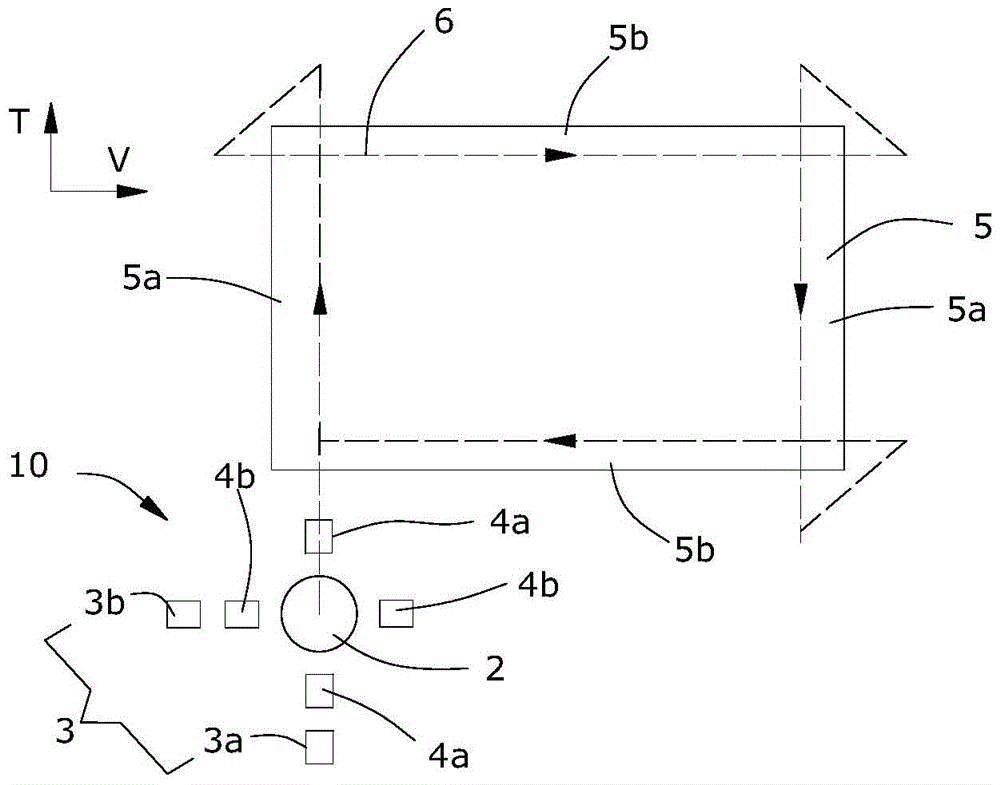

[0024] figure 1 Shown is a laser cutting device 10 according to the present invention, which is commonly known as a liquid crystal screen short-circuit ring laser cutting machine. The laser cutting device 10 can be used for cutting short-circuit rings of TFT-LCD liquid crystal panels (that is, liquid crystal panels of thin film transistor liquid crystal displays). exist figure 1 In the coordinate system shown, the T-axis represents the horizontal direction, and the V-axis represents the vertical direction.

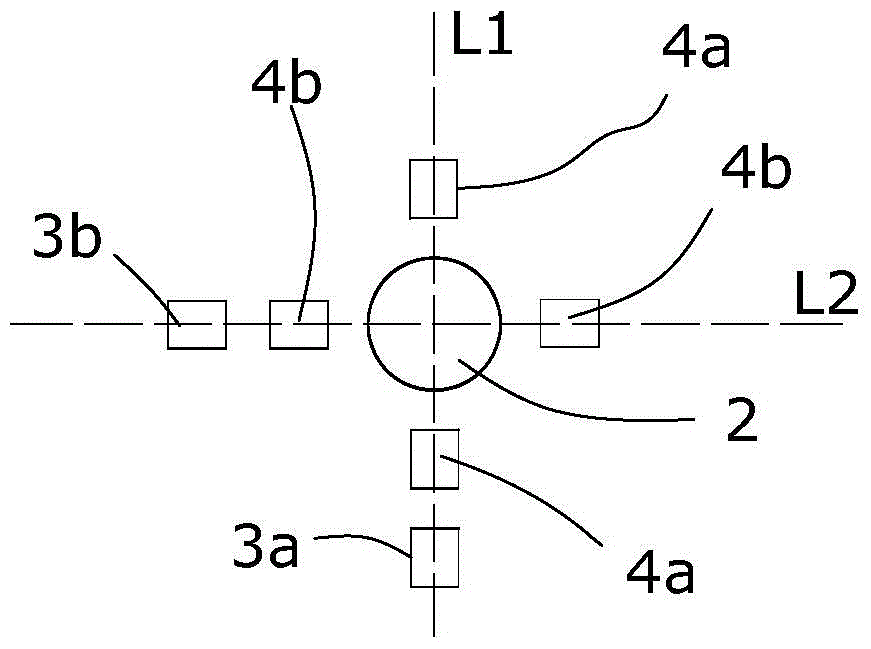

[0025] The laser cutting device 10 includes a laser cutting head 2 capable of emitting a laser beam. The pulsed laser light emitted by the laser cutting head 2 can reach an appropriate energy density after beam expansion and focusing, and cut the short-circuit ring connection line at the edge of the liquid crystal panel 5 along the moving path 6, prompting the instan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com