A pick-and-place tool for hot-pressing shells

A technology of tooling and housing, applied in the field of servo motors, can solve the problems of unsafety and low efficiency of manual picking and placing of housings, and achieve the effects of low cost, large room for material selection, and reduced labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

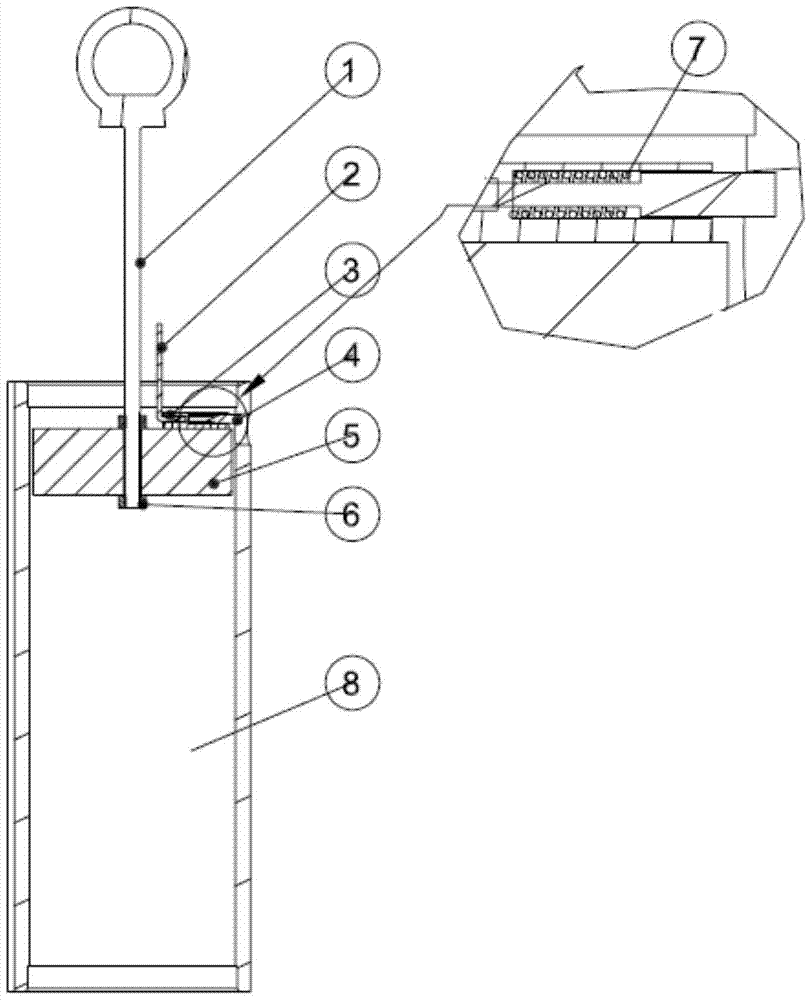

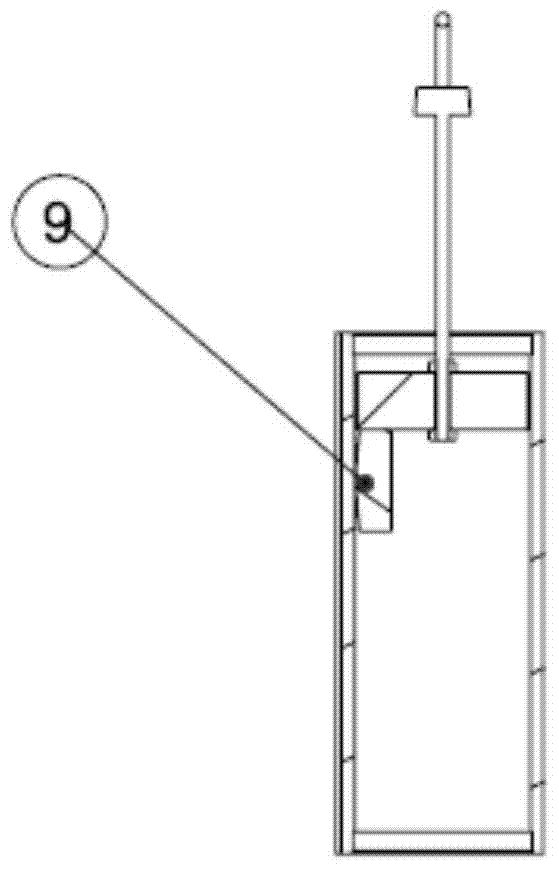

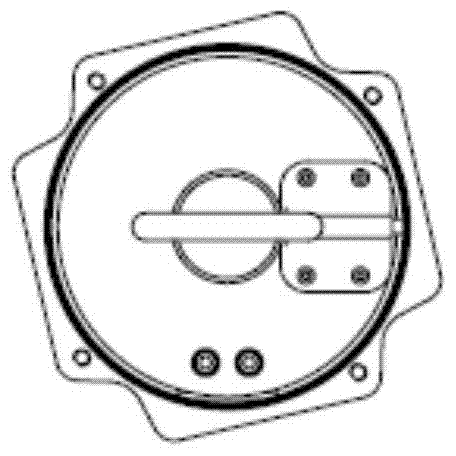

[0017] Such as Figure 1 ~ Figure 3 As shown, the present invention comprises ring screw rod 1, spring pull rod 2, hinge 3, spring push rod 4, round piece 5, nut 6, spring 7, stator housing 8, balance weight 9, and the principle of the present invention is through spring 7 When the housing is telescopically taken and placed, the spring 7 is in an extended state when the housing is taken, and the spring pull rod 2 is compressed by hand, and the spring 7 will shrink under the pressure of the spring push rod 4, so that the present invention can be put into the housing and placed After entering the corresponding position of the housing, release the spring pull rod 2 by hand, so that the spring 7 is in a stretched state, and the spring ejector 4 will be partially pushed out by the spring 7 through the tension to clamp the outlet hole of the main housing. The function of the balance weight 9 is to play a balancing role when picking and placing the housing, which is beneficial to blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com