Paper surface straw plate cutting device

A cutting device and grass board technology, which is applied in metal processing and other directions, can solve problems such as poor flatness of the grass board section, low degree of automation, and potential safety hazards, and achieve the effects of comprehensive functions, reducing manpower, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

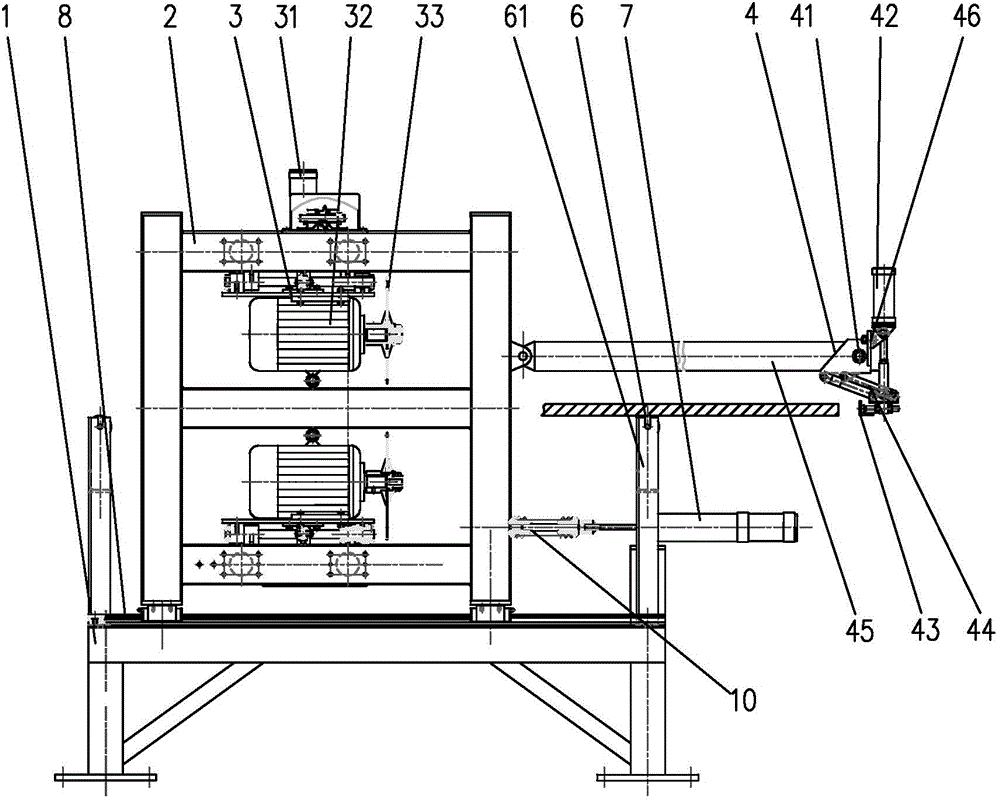

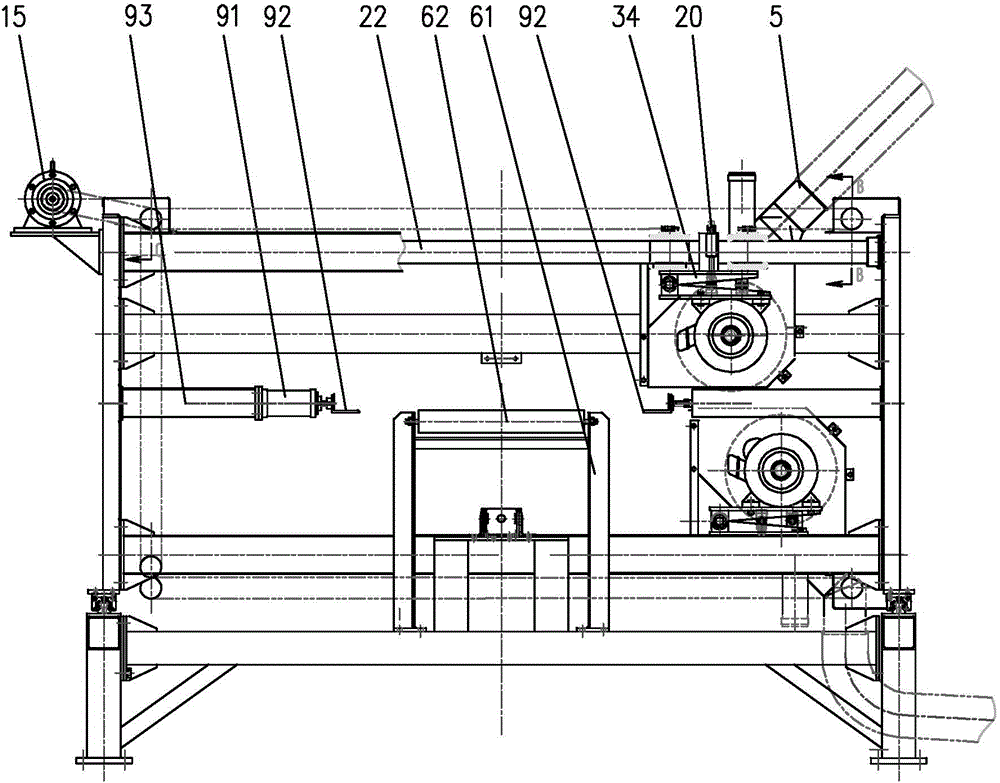

[0021] Specific implementation mode one: combine Figure 1 to Figure 7 Describe this embodiment, a kind of grass board cutting device of this embodiment comprises frame 1, follow-up clamping frame 2, cutting device 3, length measuring device 4 and dust collecting device 5, described frame 1 is The support frame structure is made of steel welded, screwed or riveted. The frame 1 is fixedly installed on the foundation. Idler devices 6 are installed on both sides of the frame 1. A horizontal push cylinder 7 is installed on one side of the frame 1. The push cylinder 7 is fixedly connected with the follow-up clamping frame 2, the follow-up clamping frame 2 is installed on the frame 1 through two linear slide rails 8, and the cutting device 3 is installed on the straight line of the follow-up clamping frame 2 through a linear bearing 35. On the guide rail 22, a draft clamping device 9, a length measuring device 4 and a dust collection device 5 are also installed on the follow-up clam...

specific Embodiment approach 2

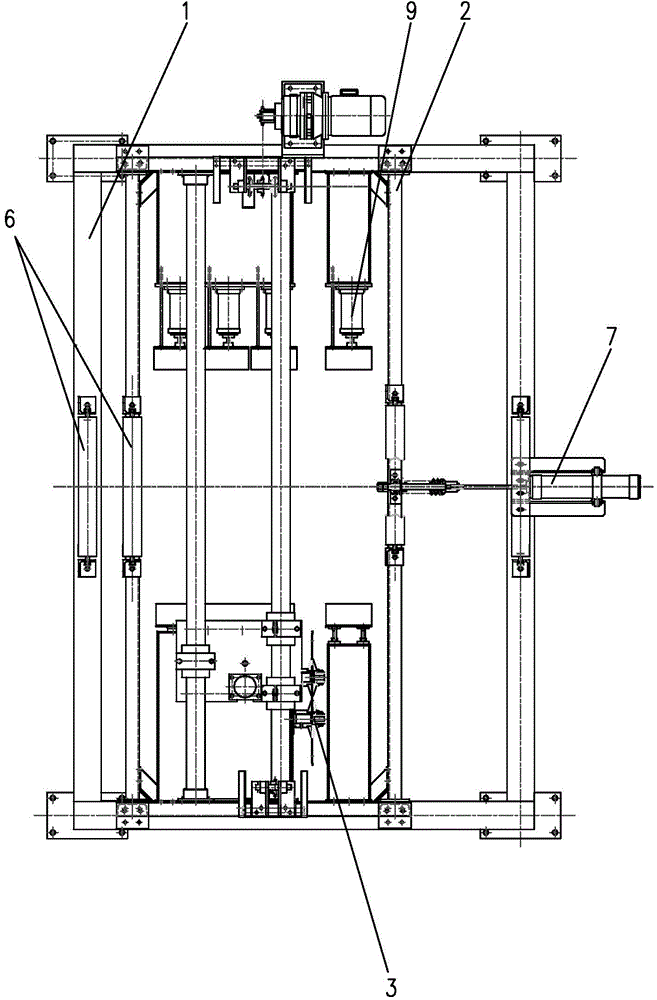

[0022] Specific implementation mode two: combination Image 6 Describe this embodiment, the described cutting device 3 of a kind of grass board cutting device of this embodiment comprises cutting cylinder 31, cutting motor 32, saw blade 33, slide plate device 34 and linear bearing 35, described slide plate device 34 The fixed slide plate 36 and the movable slide plate 37 are combined and installed by the pin shaft 38, the cutting motor 32 is installed on the movable slide plate 37, the saw blade 33 is installed on the cutting motor 32, the cutting cylinder 31 is installed on the fixed slide plate 36, and the cutting cylinder The piston rod of 31 is connected with mobile slide plate 37. In this way, the cutting saw is installed on the linear slide rail 22 on the follow-up clamping frame 2 through the linear bearing 35, the cutting saw can do translational movement, and the grass cutting saw can adjust the movement of the upper and lower saw blades by means of the telescopic mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com