A large pvc plastic pipe fitting injection mold hot runner disc pouring device

A technology of plastic pipe fittings and hot runners, which is applied in the field of large-scale PVC plastic pipe fittings injection mold hot runner disc pouring devices, can solve the problems of not meeting the requirements of injection molding, waste of condensate in the pouring system, complex structure of the pouring system, etc. Achieve the effect of reducing the overall size of the mold, low manufacturing cost, and avoiding thermal decomposition of the melt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

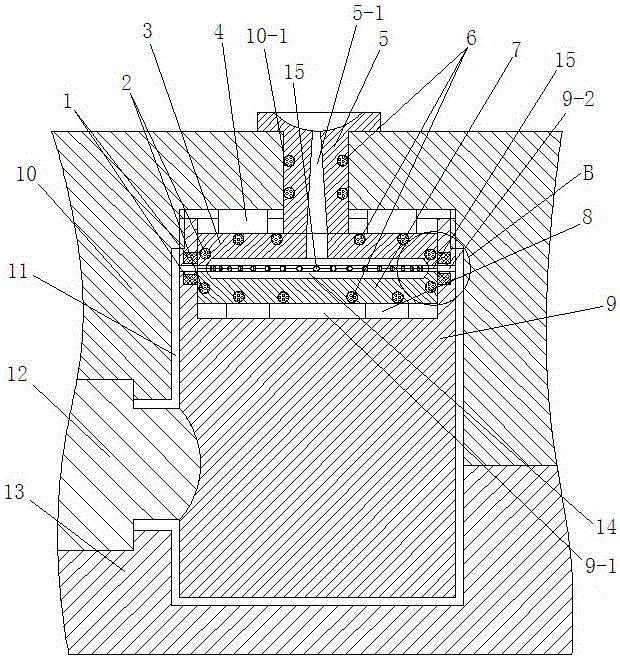

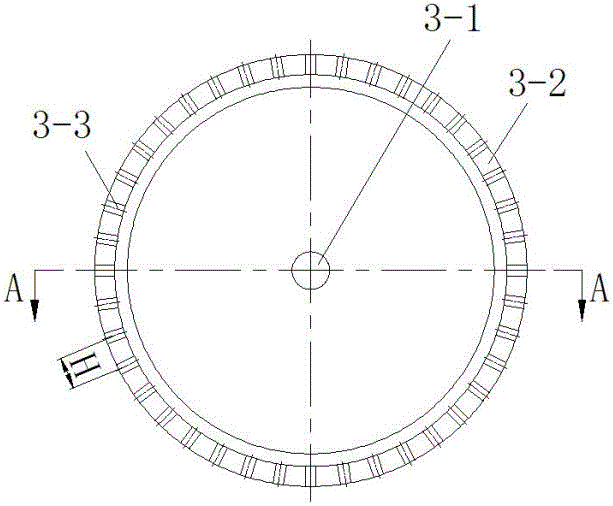

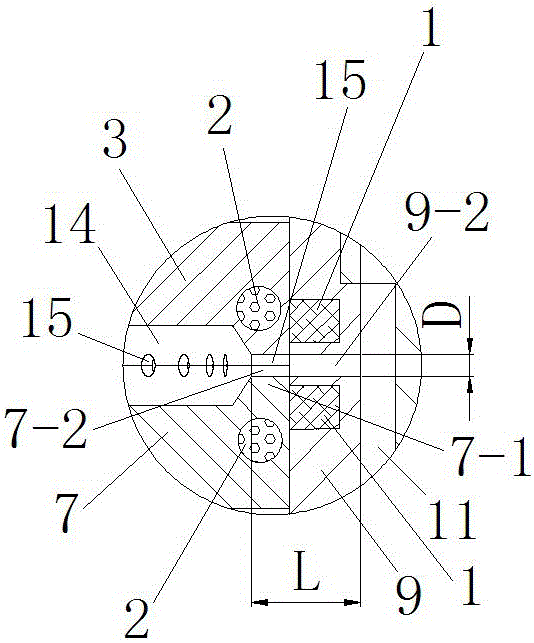

[0030] Example: see attached figure 1 ~ attached Figure 6, a large-scale PVC plastic pipe fitting injection mold hot runner disc pouring device, including a fixed template 10, a movable template 13, a mold core 9, a side-drawn core 12 and a hot runner system, and the mold core 9 is located between the fixed template 10 and the movable template. Between the templates 13, a mold cavity 11 is provided between the mold core 9 and the fixed template 10, the movable template 13, and the side-drawn core 12, the side-drawn core 12 is located between the fixed template 10 and the movable template 13, and the side-drawn The core 12 is adjacent to the mold core 9, and they are in close contact, and the fixed plate 10 is provided with a through cavity 10-1.

[0031] The hot runner system includes the main channel sleeve 5 embedded in the through cavity 10-1 of the fixed template 10, the upper disc-shaped runner plate 3, the lower disc-shaped runner plate 7, a heater, and a radiator. 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com