Novel hand-slip preventive brake pull rod for railway truck

A technology for railway wagons and brake rods, which is applied in the railway braking system, the operating mechanism of railway vehicle brakes, railway car body parts, etc. It can solve the problems of affecting driving safety and breaking of hand brake parts, etc., and achieve integrity Good, beautiful appearance, and the effect of improving the degree of commercialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings.

[0022] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

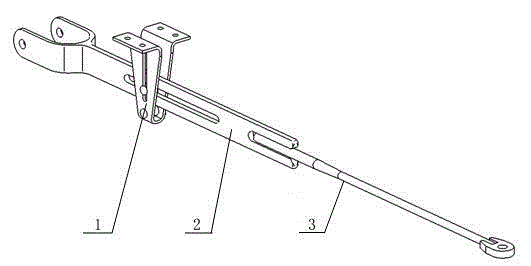

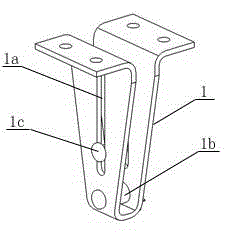

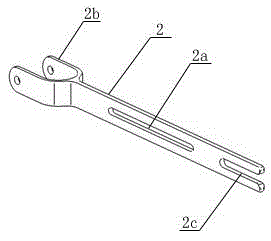

[0023] like Figure 1-5 As shown in the figure, a new type of anti-drop hand brake pull rod for railway freight cars includes a pull-off guide frame 1, a pull rod head 2 and a pull rod 3. A guide groove 1a is provided on the anti-falling guide frame 1 along its vertical direction, and the vertical freedom of the tie rod head is released through the guide groove. The head 2 is provided with an anti-separation groove 2a along its horizontal direction. The tie rod head 2 is placed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com