Efficient aerating device for water treatment

An aeration device and water treatment technology, applied in biological treatment devices, water aeration, biological water/sewage treatment, etc., can solve the problems of low work efficiency, poor aeration effect, complex structure, etc., and achieve low production cost, Excellent cycle effect and simple operation management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

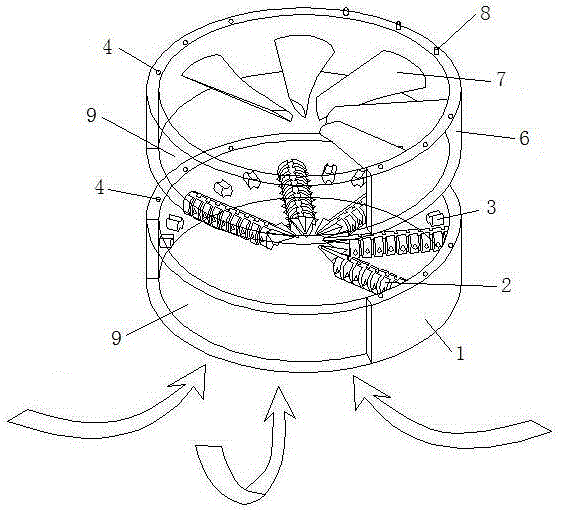

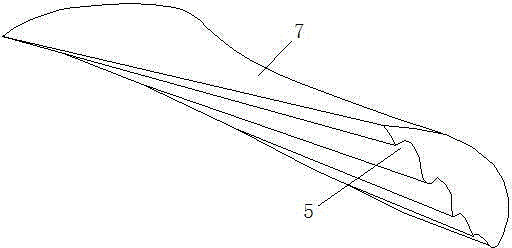

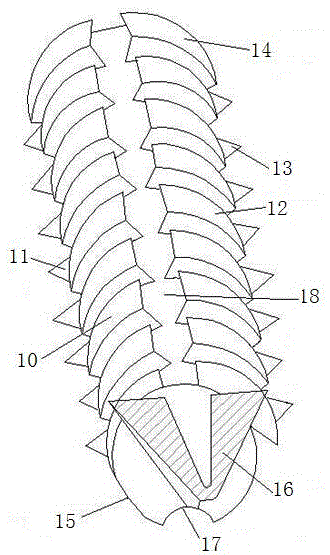

[0026] further as figure 1 After the components are assembled sequentially as shown, the air enters from the bottom of the first housing 1, and is firstly cut efficiently by the air bubble cutting structure 2 to form a plurality of small air bubbles, that is, the gas enters from the bottom of the circular aeration device during operation, and the first The first triangular cutting groove 11 and the second triangular cutting groove 13 provided on the cutting body 10 and the second cutting body 12 cut the gas, and at the same time, the gas enters through the diversion groove 17 and floats up from the water outlet 18. During the floating process, the first The polygonal structure formed between the cutting body 10 and the second cutting body 12 also cuts the gas, and the air bubbles continue to move upwards, and are effectively blocked by the air bubble barrier sheet 7 in the second housing 2, and pass through the strip groove 5 to The air bubbles are cut twice to further improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com