High temperature resistant yarn feeder yarn guiding tube

A wire feeding machine, high temperature resistant technology, applied in the field of wire conduit, can solve problems such as blockage, wire feeding interruption, cost increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

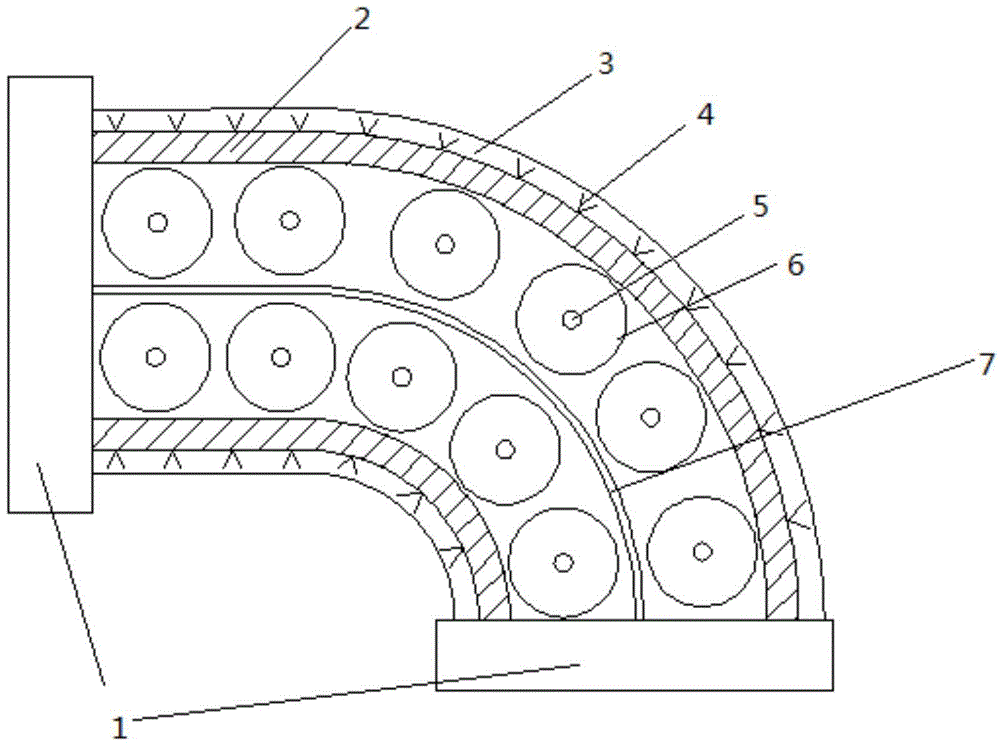

[0010] Reference figure 1 , The conduit of the high-temperature resistant wire feeding machine includes a shell 2, flanges 1 are installed at both ends of the shell 2, and the outer wall of the shell 2 is welded with V-shaped nails 4, and the welding nails 4 are partially knotted. There is a fire-resistant protective layer 3, and rollers 6 are fixedly installed on the inner wall of the casing 2. The rollers 6 are arranged in two rows, and the thickness of the fire-resistant protective layer 3 is 40mm-50mm. The roller 6 is mounted on the shaft 5 and the shaft 5 is fixedly connected to the housing 2.

[0011] Because the outer wall of the conduit is knotted with a refractory protective layer, the burning of the conduit is effectively controlled, the use time of the conduit is prolonged, the number of replacements is reduced, and the cost is saved. The rollers on the inner wall of the conduit can remove The cored wire is smoothly transported into the molten steel, especially for th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com