Remelting process of Ni-Cr-Mo anti-corrosion alloy stripping electroslag containing Ti

A technology for electroslag remelting and corrosion-resistant alloys, which is applied in the electroslag remelting process of ingot-drawing Ni-Cr-Mo corrosion-resistant alloys containing Ti, and the field of electroslag remelting technology, which can solve the problems of melting speed, production efficiency and finished product Low production rate, incapable of production and other problems, to achieve the effect of eliminating billet opening process, high production efficiency and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

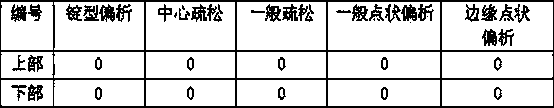

[0026] Example: 285mm×285mm×6000mm Ti-containing Ni-Cr-Mo corrosion-resistant alloy square billet electroslag remelting;

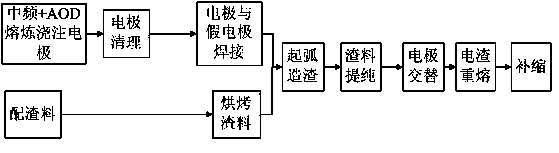

[0027] 1. Electrode preparation

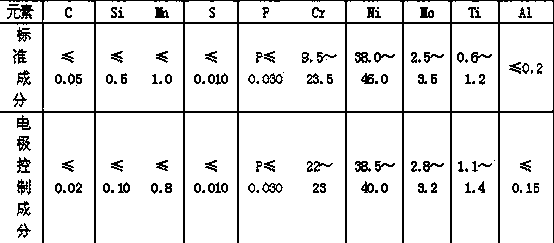

[0028] According to the requirements in Table 1, use intermediate frequency furnace + AOD smelting, cast consumable electrode, electrode size: Ф400×3880mm, weight about 3900kg, one piece. Grind off the oxide skin, slag inclusions, stuttering, oil stains, etc. on the surface of the electrode, and then weld it with the dummy electrode. The chemical composition (wt%) of the electrode is shown in Table 3.

[0029] table 3

[0030] element C Si mn S P Cr Ni Mo Ti Al Content (wt%) 0.015 0.10 0.48 0.01 0.022 22.24 39.04 3.09 1.11 0.137

[0031] 2. Electroslag remelting process

[0032] Consider comprehensively the electrode insertion depth, the safety height between the electrode end surface and the inner cone surface of the mold, the viscosity, strength, toughness, melting point a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com