Method for producing electrolytic nickel and recovering tin and iron from tin-nickel-iron alloy waste materials

A technology of iron alloy and electrolytic nickel, which is applied in the field of alloy waste recycling, can solve the problems of high price, achieve low loss rate, realize resource utilization, and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0051] Example 1

[0052] The raw material of the waste tin-nickel-iron ternary alloy in this embodiment comes from a technical production line of an electronic industry, and the output of the waste is about 100 tons / year, and its composition analysis is shown in Table 1.

[0053] Table 1

[0054] element

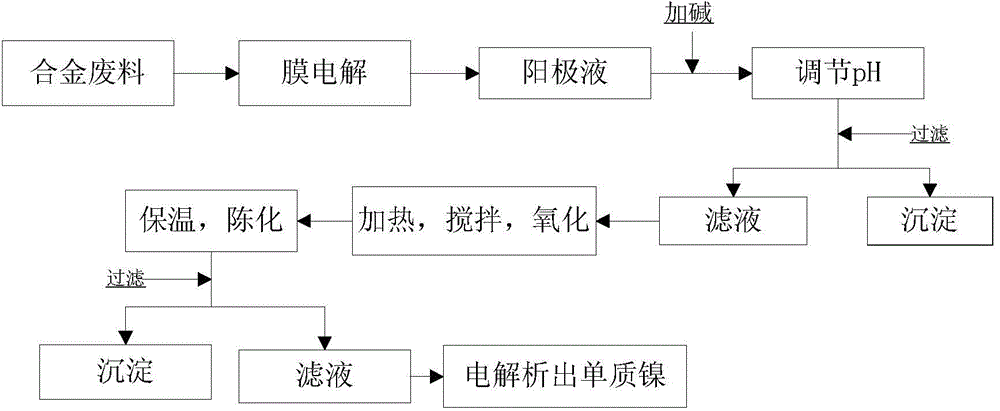

[0055] A method for producing electrolytic nickel from tin-nickel-iron alloy waste and recycling tin and iron, the method comprises the steps:

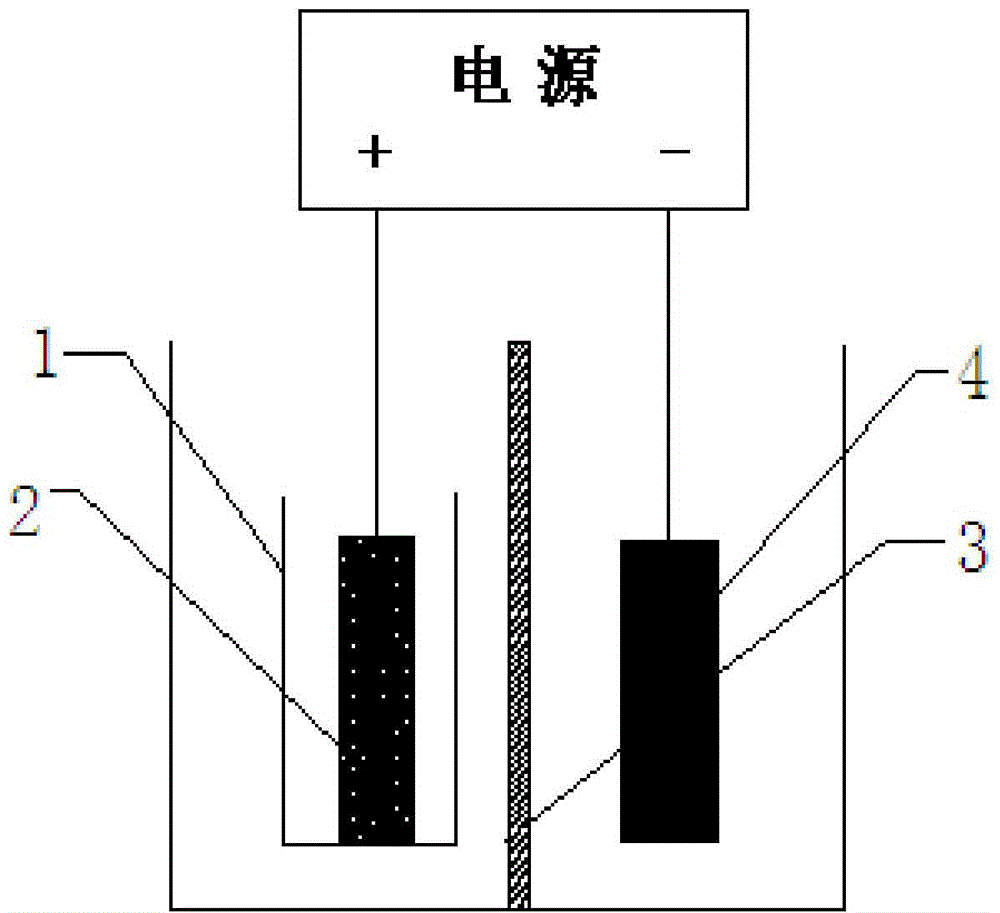

[0056] (1) Electrochemical dissolution

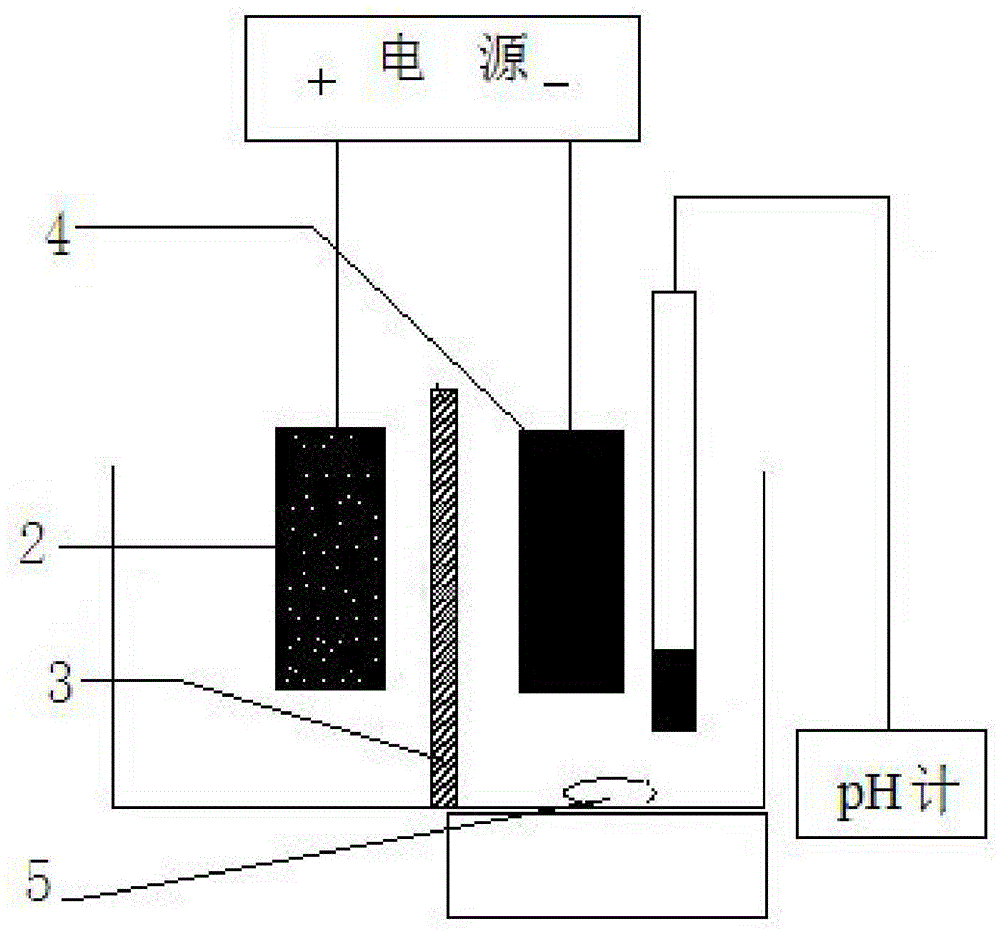

[0057] like figure 2 As shown, the activated carbon fiber bag 1 sewn with activated carbon fiber felt is used as a container, the alloy waste is a soluble anode, a graphite rod 4 is a cathode, a platinized titanium mesh 2 is a contact anode, an anion exchange membrane 3 is used as a diaphragm material, and the anolyte is composed of It is: 1.0mol / L HCl, 1.5mol / L NaCl, catholyte 1.0mol / L HCl, electrolysis voltage 1.5V, electrolysis for 8h, to obtain anolyte containing tin, nicke...

Example Embodiment

[0068] Embodiment 2

[0069] The raw material of the waste tin-nickel-iron ternary alloy in this embodiment comes from a technical production line of an electronic industry, and the output of the waste is about 100 tons / year. The composition analysis is shown in Table 2.

[0070] Table 2

[0071] element

[0072] According to the steps of Example 1, the electrolysis efficiency was 95.5%, the power consumption was 3.26kW·h / kg, and the purity of the nickel powder was 99.13%.

[0073] The XRD diffraction pattern of the cathode deposit of this example is shown in Image 6 , according to the detection method of Example 1, the spectrum at 2θ is 42.9°, 52.1°, 76.9°, and sharp diffraction peaks appear, which are consistent with the characteristic peaks of elemental nickel through computer retrieval, and Ni(OH) does not appear. 2 The characteristic peaks of 22.79°, 33.486°, 34.507°, 38.861°, 60.036°.

[0074] The deposits scraped on the cathode plate were observed by scann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap